Room-Temperature-Vulcanizing Silicone Rubber (RTV-1/RTV-2)

Room-temperature-vulcanizing (RTV) silicone rubber compounds are a traditional core competence of WACKER. The range of ready-to-use products focuses on numerous applications in the fields of bonding, sealing, potting, encapsulation, coating and casting.

Equally broad is WACKER’s experience in processing techniques and material requirements specific to these applications – from DIY-scale projects right up to industrial production lines.

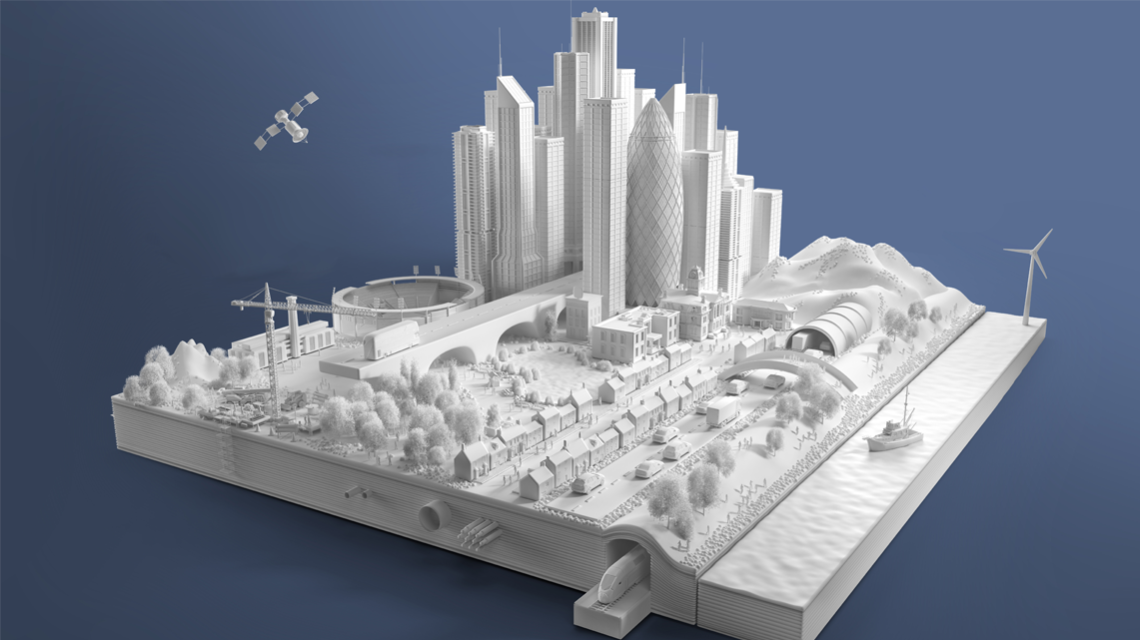

Important Applications of RTV Silicone Rubber Products

Aerospace

WACKER’s room-temperature-vulcanizing (RTV) silicone rubber products can be found in satellites and aviation.

E-Mobility

WACKER’s room-temperature-vulcanizing (RTV) silicone rubber products can be found in batteries, fuel cells, electric motors, cables and connectors.

Lighting

WACKER’s room-temperature-vulcanizing (RTV) silicone rubber products can be found in LEDs, secondary optics and luminaires.

Automotive

WACKER’s room-temperature-vulcanizing (RTV) silicone rubber products can be found in drive trains, seals, gaskets and dampers.

Appliances

WACKER’s room-temperature-vulcanizing (RTV) silicone rubber products can be found in steam irons, dishwashers, ovens, kitchen hoods and stovetops.

Energy Sector

Applications for WACKER’s room-temperature-vulcanizing (RTV) silicone rubber products can be found in the T&D, the oil and gas, and the solar, wind and hydroelectric power industries.

Electronics

WACKER’s room-temperature-vulcanizing (RTV) silicone rubber products can be found in automotive electronics, consumer electronics and power modules.

Health Care

WACKER’s room-temperature-vulcanizing (RTV) silicone rubber can be found in wound and ostomy care products, wearables, medical tapes, orthopedics, prosthetics and dental care applications.

Transportation

WACKER’s room-temperature-vulcanizing (RTV) silicone rubber products can be found in utility vehicles, the marine industry and railway systems.

Fire Safety Applications

WACKER’s room-temperature-vulcanizing (RTV) silicone rubber products can be found in seat cushions and in seals for cables and pipe ducts.

Mining & Exploitation

Applications for WACKER’s room-temperature-vulcanizing (RTV) silicone rubber products can be found in the mining and exploitation industry.

Food Industry

WACKER’s room-temperature-vulcanizing (RTV) silicone rubber products can be found in baking-tray coatings and as molds for chocolates and dessert decorations, etc.

Mold Making & Prototype Molding

WACKER’s room-temperature vulcanizing (RTV) silicone rubber is used in molding, prototyping and pad printing. Example applications include RTV molds in arts and craft, molds for concrete casting, molds in the tyre design and production process and the molding of composite parts.

One-Part Room-Temperature-Vulcanizing Silicone Rubber (RTV-1)

One-part room-temperature-vulcanizing (RTV-1) silicones are ready-to-use systems consisting of polysiloxane, a curing agent, fillers and additives. Immediately after application, the material starts crosslinking on contact with moisture in the air. Byproducts are released during curing. Crosslinking starts with the formation of a skin on the rubber surface and gradually progresses into the compound. Depending on the nature of the crosslinker, small amounts of acetic acid, amine or neutral byproducts, such as alcohol, are released during vulcanization.

RTV-1 silicones are ideal for sealing, bonding and coating applications in nearly all industries, such as

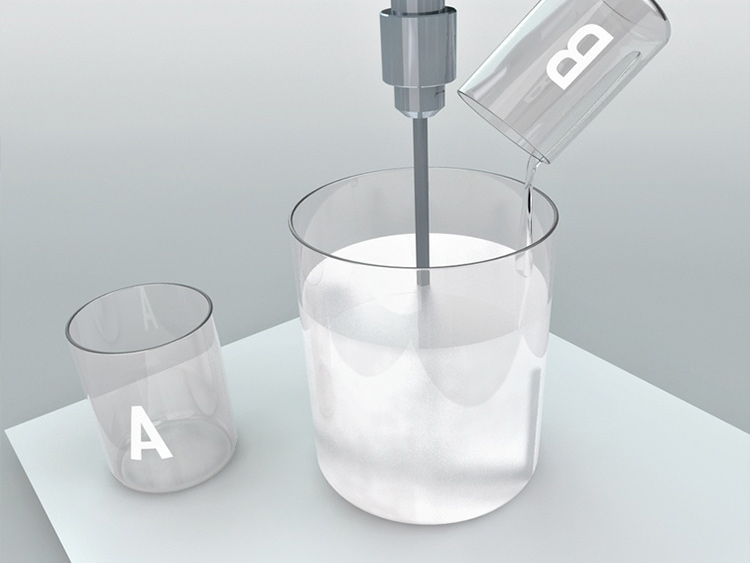

Two-Part Room-Temperature-Vulcanizing Silicone Rubber (RTV-2)

Two-part room-temperature-vulcanizing silicones (RTV-2) are pourable, spreadable or kneadable formulations that vulcanize after mixing. There are two different types of crosslinking reactions: by condensation or by addition. Condensation curing requires an organotin catalyst and always releases byproducts. Addition curing requires a platinum catalyst and does not generate any byproduct.

Special RTV-2 silicone rubber grades can be flash vulcanized using UV light. The vulcanization time can be controlled by adjusting the UV intensity and exposure time.

Like RTV-1 silicones, RTV-2 formulations are ideal for almost all sealing, bonding and coating applications, where they are used for the following:

Room-Temperature-Curing Silicone Rubber (RTV-2)

Thermally Curing Silicone Rubber (RTV-2)

Addition-Curing Silicone Gels and Silicone Foams (RTV-2)

Silicone Gels

Silicone gels are characterized by a particularly low crosslinking density and produce very soft cured rubber below the Shore hardness range. They are suitable for various applications in industries such as

Developed especially for the automotive industry, gels such as low-temperature flexible gels and fluorinated materials exert only minimal stress on encapsulated components exposed to temperature fluctuations.

Silicone Foams

Silicone foam formulations are characterized by a high concentration of an SiH-rich polysiloxane crosslinker. The basic function of this compound is to crosslink the liquid formulation and release hydrogen, which acts as a blowing agent as curing progresses. Silicone elastomer foams are typically used in applications such as

Brochures

ELASTOSIL® SEMICOSIL® | Silicones for Industrial Sealing and Bonding Applications

DownloadELASTOSIL® | Silicone Rubber for Industrial Coating or Sealing Applications

DownloadELASTOSIL® SEMICOSIL® WACKER Silgel® | Silicone Rubber for Industrial Potting, Encapsulation or Casting Applications

DownloadSILPURAN® | ELASTOSIL® | Silicone Rubber | Health Care | RTV Silicones for Medical Applications

DownloadELASTOSIL® Color Paste FL | Product Overview

DownloadELASTOSIL® M | Silicones for Moldmaking Compounds | Product Selection Guide

DownloadSILICONES – Definition and Properties

Want to know more about WACKER silicones?