Innovative Silicone Films

WACKER silicone films are ultrathin, high-precision films of crosslinked silicone rubber which are available as roll stock in various thicknesses from 10 to 400 μm, and in sheets. The silicone film is manufactured under cleanroom conditions entirely without solvents.*

Our patented process means that the maximum thickness variation across the film width is ±5%. This precision, combined with the proven properties of silicone rubber, opens up entirely new opportunities: it paves the way for applications that, until now, have been almost inconceivable, let alone realizable on an industrial scale.

*Thicknesses under 20 µm have an absolute thickness variation of +/- 1 µm.

The silicone film is available in two different forms:

ELASTOSIL® Film Applications

Marketed as ELASTOSIL® Film, the silicone film is ideal as a high-precision dielectric layer in innovative and pioneering electroactive polymers (EAPs) – for instance as actuators, smart sensors and generators. For example, it can be used to make artificial muscles or valves that convert energy into motion.

Thanks to its characteristic silicone properties, the film can also be used in smart textiles and in power plants to extract energy from sea waves. Of course, ELASTOSIL® Film can also be used in other applications, such as ultra-precision insulation layers or as a gas diffusion membrane.

What’s more, our range of silicone film products includes liquid silicone rubber (LSR) grades from WACKER’s standard portfolio. ELASTOSIL® 3003, between 400 and 1,000 µm, SILPURAN® 6000 and POWERSIL® XLR 630 are now available as fully crosslinked films and can be used in a great many industrial applications, such as in the automotive, medical and electrical engineering sectors. Major advantages of LSR films include their high transparency and their excellent mechanical and electrical properties.

Benefits:

SILPURAN® Film Applications

SILPURAN® Film from WACKER is an exceptionally skin-compatible, protective film made of crosslinked silicone rubber, specially developed for the health-care industry. Available in a variety of thicknesses (10 to 400 µm), this film is manufactured under cleanroom conditions using innovative production technology.

SILPURAN® is the perfect choice for manufacturing breathable, atraumatic wound dressings that provide optimum support for the healing process. This novel silicone film can also be used as a gas-permeable membrane in other medical devices, such as heart-lung machines.

Benefits:

Benefits:

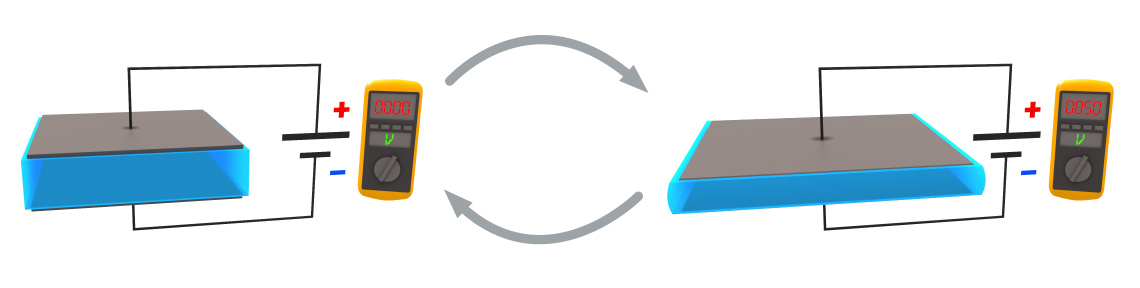

NEXIPAL® for Electroactive Polymer (EAP) applications

NEXIPAL® is an EAP laminate comprising layers of electrodes and ultrathin silicone films which act as permittivity layer. It can expand and contract on demand and therefore converts electrical energy into movement. Further, NEXIPAL® enables the production of capacitive sensors and actuators. This makes silicone laminates interesting not only for consumer electronics and the automotive industry, but also for sensor technology, robotics as well as athletic and lifestyle applications.

SILICONES – Definition and Properties

Want to know more about WACKER silicones?