Eastern Europe

Approx. 17.2 % (approx. 57 millionm2)

Climate change, energy shortages and rising heating costs have given a real boost to external thermal insulation composite systems (ETICS) in recent years. This technology for insulating facades from the outside with rigid polystyrene foam panels, mineral wool and the like is now commonly deployed around the world. In many countries, it even attracts government subsidies for being an efficient climate protection measure.

The first external thermal insulation composite system (ETICS) was applied to a residential building in Berlin in 1957. Initial reactions were somewhat subdued. It would be the mid-1960s before ETICS were installed on a large scale. Today, almost 70 years later, they can be found on facades all around the world, from America to China. How did it all come about?

Europe is a growth market for ETIC systems, with consumption there expected to exceed 205 million cubic meters in 2024. However, there are huge differences in terms of regional distribution. Densely populated Central Europe accounts for some 43 percent of all installed ETIC systems, while Northern and Western Europe represent only a small proportion. The reasons for this are many and varied. Demographic factors play a part, but so too do regional differences in construction methods, the ratio of new builds to refurbishments, statutory energy-saving requirements, and government subsidies.

Approx. 17.2 % (approx. 57 millionm2)

Approx. 0.6 % (approx. 2.1 millionm2)

Approx. 5.8 % (approx. 19.4 millionm2)

Approx. 42.8 % (approx. 142 millionm2)

Approx. 13.0 % (approx. 43.3 millionm2)

Approx. 20.6 % (approx. 68.2 millionm2)

One factor behind the spread of ETIC systems is growing awareness of the need for environmental and climate protection. Recent years have seen governments around the world committing to ambitious climate targets. Europe, for example, is seeking to become completely climate-neutral by 2050 under the EU Green Deal. This is targeting a reduction in greenhouse gas emissions of at least 55 percent by 2030, compared with 1990 levels. China, which accounts for nearly one-third of global emissions, is aiming for carbon neutrality by 2060. And the USA has also set itself climate targets with the promulgation of its Inflation Reduction Act (IRA).

These climate targets can only be achieved with efficient measures for insulating buildings. After all, buildings are responsible for 40 percent of primary energy consumption worldwide and account for for 33 percent of CO2 emissions. ETIC systems slash energy consumption and harmful emissions. Many countries, such as Germany, see energy-efficient building refurbishment with ETICS as an important component of climate protection and offer state subsidies accordingly.

Non-refurbished legacy buildings

* In Germany

Source: German Foreign Office

Refurbished legacy buildings

New buildings

Passive houses

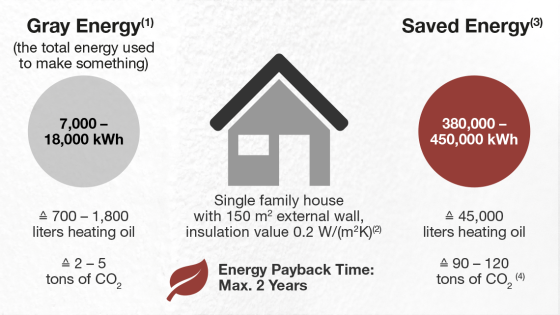

(1) Varies with material and recycling method; (2) minimum value for financial support in Europe; (3) within 30 years of installation, depending on building’s state of repair and climate; (4) for a heating system burning fossil energy (gas, oil)

Over 600 billion kWh of energy is consumed each year by German households. More than two-thirds of it goes on heating. Efficient facade insulation can reduce consumption of heating energy by up to 70 percent – and slash CO2 emissions.

Of course, energy is consumed and upfront costs incurred in the production and installation of an ETIC system. However, both can usually be amortized within 2 years at most. Given that an ETICS has a lifespan lasting decades, its benefits vastly outweigh the costs.

Even in warm regions, facade insulation is a hot topic – quite literally. For, insulation not only keeps out the cold, but also the heat. And the less a building heats up, the less energy is needed to cool it.

To measure this effect, WACKER built and tested two virtually identical model houses in Dubai. The interior temperature of both was kept at a constant 23 °C. But only one was fitted out with an external thermal insulation composite system. The results were unequivocal: the insulated house consumed 60 percent less energy and generated 60 percent lower CO2 emissions.

Learn more about the WACKER model house project in Dubai.

A number of different insulation materials are used in an ETIC system: from expanded polystyrene (EPS) and mineral wool to wood fiber and hemp. EPS and mineral wool account for almost 90 percent of the global market for ETICS. Both materials are excellent insulators, inexpensive and easy to handle. Mineral wool also offers a high fire-safety rating.

But no matter which insulation material is used, an ETICS must always be treated as a complete system. From adhesive mortar to base coat to plaster – all the components must be perfectly matched. That is the only way to ensure that the ETIC system performs reliably down through the years.

With an ETIC system, the insulation material is installed on the outside wall. Special adhesive mortars are needed to ensure that synthetic and mineral insulation materials, such as EPS and mineral wool, form a permanent bond to the substrate. This calls for versatility because every facade differs in terms of when, where and from which material it was built. The solution: VINNAPAS® dispersible polymer powders and dispersions from WACKER. These polymeric binders not only strengthen the adhesive bond between the insulation panels and the various substrates but also boost the flexibility and impact strength of the entire ETIC system.

WACKER offers a wide range of products to suit different applications, climate zones and substrates. Visit our product section for details.

To the product portal