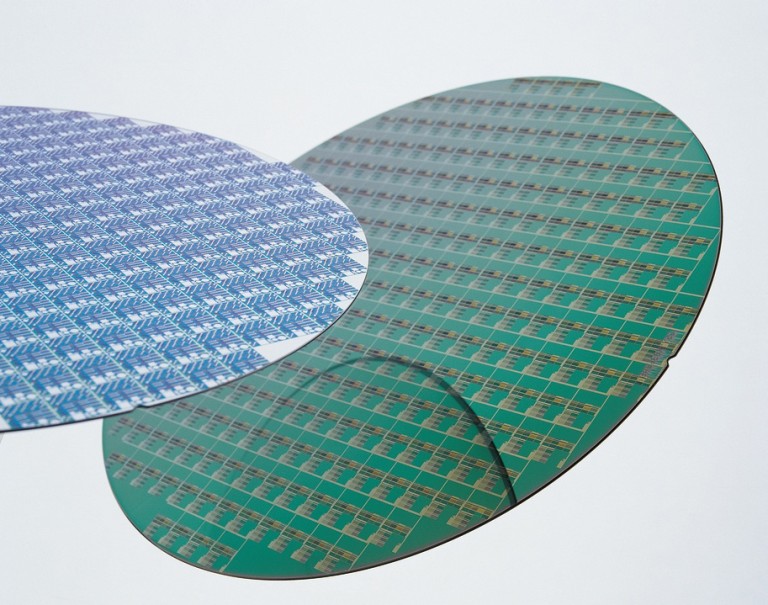

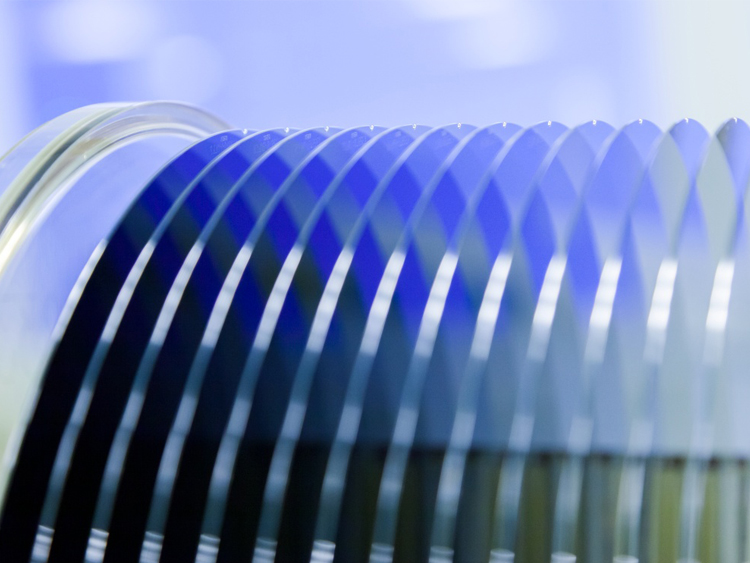

Electronic Chemicals for the Semiconductor Industry

High purity combined with extremely low metal contamination make SEMICOSIL® electronic silanes a key material for the semiconductor industry. As one of the world’s largest producers of silanes, WACKER boasts an innovative portfolio of additives for producing microelectronic components, raw materials for process optimization and precursors for depositing insulating layers in CVD chambers.

Silanes for Chemical Vapor Deposition (CVD) and Spin-On Dielectrics (SOD)

Benefits:

Applications:

Silanes for Photolithography

SEMICOSIL® silazanes are used as additives for microelectronic applications and as raw materials for process optimization in the field of lithography.

Benefits:

Applications:

Silica for Chemical-Mechanical Polishing (CMP)

HDK® I13 is used as an abrasive component in slurries for chemical mechanical polishing (CMP).

Benefits:

Applications:

Hyperpure Hydrogen Chloride for Etching

SEMICOSIL® HCl 5.5 is a hyperpure hydrogen chloride that meets the strictest quality requirements for semiconductor manufacturing.