PCIM Asia 2016: WACKER Presents Gap Filler for Electronics Applications and Heat-Resistant Gel in China

Shanghai, Jun 23, 2016

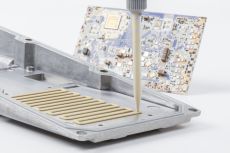

WACKER will showcase a new heat-conducting silicone-based gap filler material for the Chinese electronics industry at the Power Conversion and Intelligent Motion electronics tradeshow (PCIM Asia). Available under the trade name SEMICOSIL® 961 TC, the silicone rubber is characterized by good flow and processing properties. Furthermore, wear of the mixing and metering equipment used in its application is low. It is ideal as an interface material for thermally connecting electronic circuits, ensuring effective heat management. Meanwhile, WACKER will also present SEMICOSIL® 915 HT, a silicone gel which is heat-resistant up to 210 degree Celsius. It is ideal for encapsulating power electronic modules. This year’s PCIM Asia will take place in Guangzhou, China, from June 28 to 30.

SEMICOSIL® 961 TC is a highly filled, two-part silicone rubber that cures at room temperature via a platinum-catalyzed addition reaction to form a soft silicone elastomer with a tacky surface. The cured rubber achieves a thermal conductivity of two watts per meter kelvin and, at the same time, is electrically insulating. Its shear-thinning property is adjusted so that the silicone rubber can easily be fed by machine and applied as a bead. Processors can achieve a high metering rate and very high dosing accuracy.

In practice, SEMICOSIL® 961 TC forms a continuous film that conforms snugly to the surfaces of the two joining parts to ensure optimum heat transfer from the electrical circuit to a heat sink.

The film cures to form a silicone layer between the joining parts. Thanks to its soft consistency, it ensures a reliable, tight fit even if there are frequent temperature changes and vibrations. In addition, the new silicone gap filler can be used over a wide temperature range. Its properties remain unchanged between -45 and +180 degrees Celsius. High thermal and thermal-shock resistance and the ability to absorb vibrations are important for applications in automotive electronics and electromobility, for example.

SEMICOSIL® 961 TC is a two-component system. Despite its high filler loading, it has a comparatively minor abrasive effect on the mixing and metering equipment used to apply it. This means that there is less abrasive damage to feed pumps, for example, than is usually the case with highly filled silicone rubber. Consequently, significantly longer service lives of mixing and metering equipment and major cost advantages in processing are possible. Additionally, the new gap filler contains hardly any volatile components. In terms of fire-safety properties, tests show that the silicone product meets the specifications for classification V-0 as per UL 94 of Underwriters Laboratories.

During PCIM Asia 2016, WACKER will also present SEMICOSIL® 915 HT, a silicone gel that is characterized by extreme heat resistance after curing. This is evidenced by the fact that the mechanical properties of the cured rubber remains stable even after 2,000 hours’ exposure to 210 degrees Celsius. The gel is therefore ideal for encapsulating power electronic modules. When regulating high electrical power, these modules can become so hot that conventional silicone gels fail.

The gel is a two-component, addition-curing product. It is typically used to encapsulate power electronic modules employed in energy technology, high-speed trains and industrial plant. SEMICOSIL® 915 HT acts as a safeguard for manufacturers of power electronic modules against more exacting demands that will arise in the future, because the extremely heat-resistant encapsulant has the capacity to cope with much higher power densities than before.

Visit WACKER at PCIM Asia, Booth D21

Contact

Wacker China

Media Relations & Information

Jessica He

Phone:+ 86 21 6130 2588

Email jessica.he@wacker.com

Send Message