Silicone rubber

Oct 19, 2022 Read time: approx. MinutesMinute

Personalized Prostheses

The startup Newteam Medical from Toulouse in the South of France manufactures breast prostheses from silicone rubber that can be individually adapted to the patient’s anatomy. They are amazingly life-like and give cancer patients back some of their quality of life.

Where can I find Newteam Medical? Down at the end, the second to last door on your left!” The caretaker behind the high railing fence holds the gate open and points the way through several austere-looking office buildings and warehouses. The Saint-Jory industrial estate, roughly half an hour’s drive from the southern French city of Toulouse, is the epitome of functionality, though you soon forget your surroundings when the head of Newteam Medical, Leonarda Sanchez, opens the door. Sanchez exudes South American warmth, energy and zest for life: she vivaciously greets her visitors and straight after the first “bonjour” apologizes for the startup’s humble abode. “We’re a very small team, a real startup,” she says, all smiles.

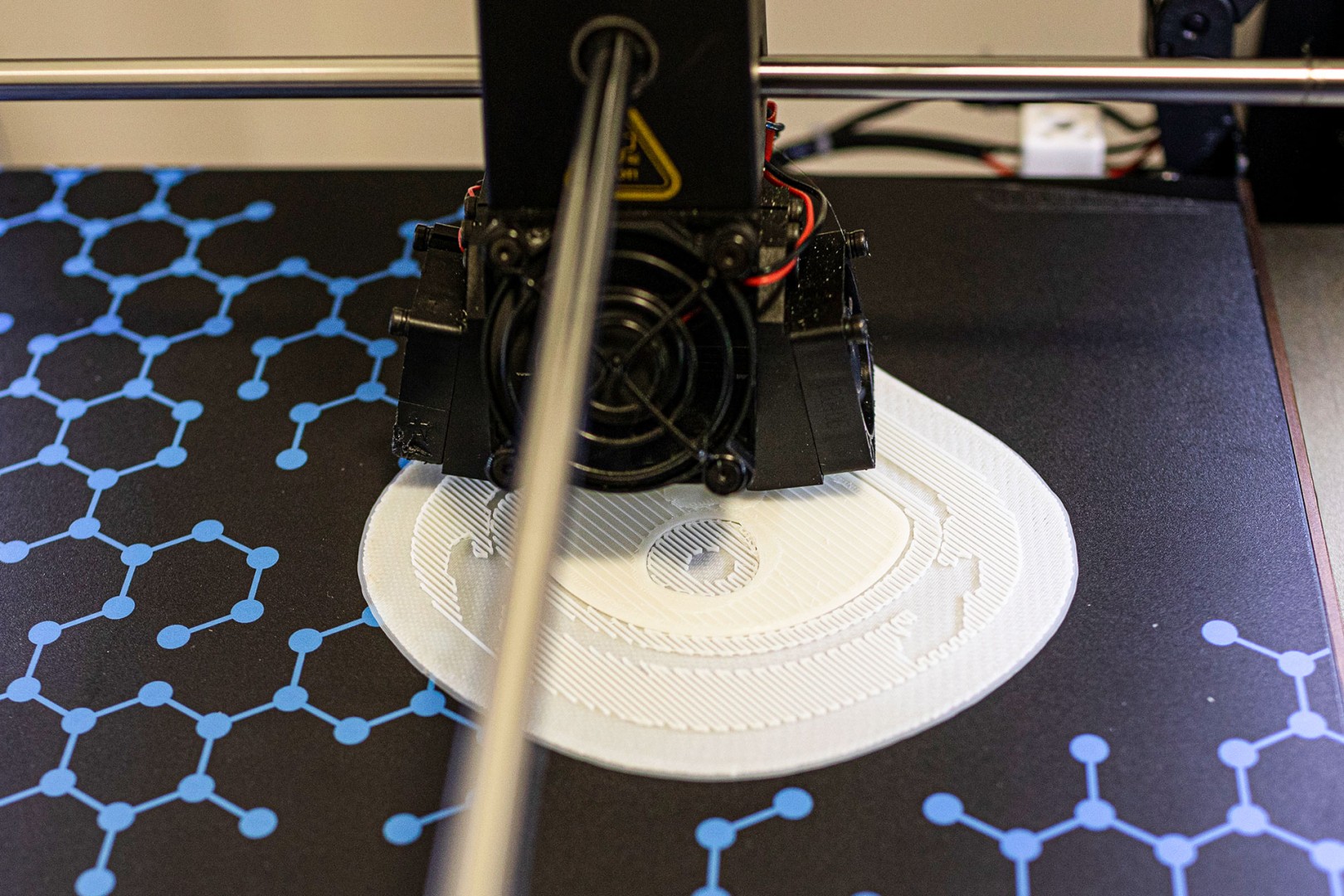

The primer is dabbed onto the slightly translucent prosthesis.

Ten Years in Development

The premises are indeed limited. So much so that the few employees work shifts as there is not enough space for them all to be there at the same time. The functionality found outside is mirrored here indoors on a smaller scale: a polished metal table is the focal point of the first room. On the table are scales and a few amazingly life-like breast prostheses laid here to dry as the temperature-controlled drying cabinet next door is already full. Under the large table there is a stack of trash cans to mix silicone in, on the shelf opposite are metal molds, all carefully arranged according to size. The next room is somewhat cozier where two employees are sat concentrating on their work.

Leonarda Sanchez excitedly gives us a tour of her small realm, alternating between being communicative and remaining reserved for fear of inadvertently disclosing company secrets. This is because these products, which have only been on the market since 2021, are the result of a decade of research and several patents. The three product groups offered by Newteam Medical are called Air’avanti, Meavanti and Suitavanti and they differ in many respects from the standard prosthetics on the market. “Our prostheses are personalized and always state-of-the-art. We have patents in France, the EU and even one in the USA. Three unique aspects have been acknowledged,” she explains with great pride and joy with regard to what has been achieved. It all began with a personal stroke of fate.

Prostheses in Days Past: Heavy and Uncomfortable

Sanchez got thyroid cancer in 2010, while her friend came down with breast cancer. Confronting the illness completely changed the life of this mother of three. While she beat the cancer, her friend had to undergo a mastectomy, i.e., have her breast removed. “She was not the only one in my circle of friends. To lose such an intimate part of the body is unbearable.” Sanchez experienced the difficulties women face afterwards, both psychologically and on a practical level with conventional prostheses. “Standard prostheses were very heavy back then and caused acute back problems for most women due to the imbalance of the two breasts, not to mention the volumes that were often wrong and failed to produce visual harmony.”

The prostheses shown are called AIR’AVANTI. They are being cleaned in the tunnel on the right. Quality control is the next stage.

An AIR’AVANTI prosthesis is sanded by hand.

Wearing Comfort and Aesthetics

Leonarda Sanchez told herself that there had to be a better way of doing things and set to work without any prior knowledge of medicine, chemistry or materials science. “I am a tinkerer and my mathematical background during my early career has always helped me. When I come across a problem, I look for a solution and keep going until I have found one.” For three years the 51 year old experimented in her kitchen. She carried out the first tests with natural materials such as plants or corn and finally came across silicone. “Our products have to meet stringent health standards and regulations, which have become stricter since 2017. Only silicone can meet these requirements.”

But on this point, she was not satisfied with commercially available products either. Sanchez quickly realized that she needed her own formula. “I first contacted chemists because I didn’t even know that you have to mix the A and B components when working with silicone,” she smiles in retrospect. She regularly exchanges information with experts and works closely with clinics, but over the last ten years she has acquired a vast amount of knowledge herself. At the outset, the goal was only to make the prostheses lighter and fit in terms of volume. Nowadays, Meavanti and Suitavanti prostheses take that much further by trying to imitate the amputated breast as regards weight, volume, shape, skin color and nipple, down to the smallest blemishes such as moles, visible veins and blood vessels. The prostheses are also adapted to the thorax, the rib cage, to ensure maximum comfort.

“Our products have to meet stringent health standards. Only silicone is able to fulfill these requirements.”

Leonarda Sanchez

Customization takes parameters such as skin tone and individual pigmentation into consideration.

Proprietary Software

Several individual steps are required to achieve this. “Each breast has its own weight. Regardless of cup size or volume.” Newteam Medical uses its own program based on AI, a scanner and its own algorithm to measure the weight of the breast. The margin of error is minimal with discrepancies of 10 grams at most. Initial data is collected by trained contractors who use performance specifications to gather information from customers regarding weight, shape, volume and skin color. Once the data has been anonymously transferred to the headquarters in Toulouse, production can begin. A Meavanti prosthesis consists of several individual parts which are pieced together in the course of production. Newteam Medical uses WACKER’s room-temperature-vulcanizing silicone rubber compounds from the ELASTOSIL® and SILPURAN® ranges.

The Key to Success? Silicone!

“I have been experimenting for a long time to find the perfect formula. Each type of silicone has different properties. Both the WACKER silicones I use today have properties other manufacturers are unable to supply,” Sanchez explains without going into any more detail so as to protect intellectual property.

Few operators have been working on the painstaking job of painting silicones. Newteam Medical has invested many years of R&D in developing customized painting procedures. The first step is mixing the matching skin color from silicone paints. Due to the low surface tension, silicones can only be painted using special paints which are also based on silicone. For the sake of skin compatibility and wearing comfort, Newteam Medical only uses the best paints available on the market.

What is more, Newteam Medical employs art college trained students specialized in realistic painting, such as Laurent Cartier. The painting techniques developed by Newteam Medical allow Cartier to dab on the silicone paint with a cloth and then carefully paint on small blood vessels, veins, freckles, moles and the nipple with a brush. The result reproduces a real breast very closely. Laurent Cartier says, “Painting on silicone is completely different from painting on canvas. You have to be very quick as the paint dries fast. The customization lasts for two years, thanks to our technique.” Once the prosthesis has been painted, the appropriate weight is inserted and the rear side is sealed with a silicone backing.

It takes 10 minutes for the WACKER silicones used in the MEAVANTI prostheses to cure in the drying oven.

The individual parts of the prosthesis are cured in the drying oven.

Leonarda Sanchez founded Newteam Medical, a company dedicated to the highest quality and the needs of women affected by breast cancer.

Innovations for Highly Sensitive Skin

External prostheses may be supplied as padding in a special bra or as prostheses which adhere to the skin. In this case, another layer of silicone is applied. “We also use a product from WACKER for this. It is fantastic. It adheres to the skin and is not painful at all when you remove the prosthesis,” she enthuses.

Newteam Medical has also come up with a solution for women with particularly sensitive skin or for those who have been recently operated on where the scar tissue has not yet formed. The Airavanti model is also made of silicone but has a mesh structure which allows the skin to breathe and does not touch the scar at all. This is a real breakthrough as women are not normally able to wear silicone prostheses directly after having had a mastectomy. For patients who are unable to wear any kind of standard prosthesis, for instance because their rib cage is uneven, there are even customized designs: Sanchez calls this range of custom-designed prosthetics Suitavanti.

“The feedback we get from women shows that our effort is all worthwhile. Some women write telling us that they have been back to the beach for the first time or that they finally have the confidence to be photographed again.” Several women sent unsolicited photos of their breast. Although the products cost almost three times as much as standard prostheses and there is up to one month’s wait for a prosthesis, demand is continuously increasing.

“But what really counts for me are women and the quality of life we give back to those affected by breast cancer.”

Leonarda Sanchez

Positive Result

To date, there have been virtually no complaints. There is a two-year warranty on Newteam Medical’s products. These prosthetics are not yet subsidized by French health insurers. However, Leonarda Sanchez is hopeful that this will change. She is conducting a long-term study with IUCT Oncopole Toulouse, a university cancer institute, to prove the positive impact personalized prosthetics have on the psyche, as well as wearing comfort and health aspects.

The small company is growing more quickly than expected. Two new employees have been hired and the company also plans to move to newer and larger premises. “But what really counts for me are women and the quality of life we give back to those affected by breast cancer,” Leonarda Sanchez emphasizes. “I know every woman I have sent a prosthesis to, every single one. Everything else can wait.”

To give the skin a natural look, the silicone-based paints are mixed individually.