Engage the Experts

pDNA, mRNA, and LNP Solutions from Research to Commercialization

Wacker Biotech is your CDMO partner for the entire manufacturing chain of plasmid DNA (pDNA) and messenger RNA (mRNA) to lipid nanoparticle (LNP) formulations. We leverage our global team of development, process engineering, and manufacturing experts and a network of state-of-the-art facilities to accelerate our partners’ programs from research phase to the market.

Contact usYou benefit from our decades of experience in complex protein-based therapeutics, vaccines, and specialty chemicals sectors, including partnering with the German government to respond to the Covid-19 pandemic.

We invite you to explore this page and discover Wacker Biotech’s end-to-end services, including pDNA, mRNA and LNP capabilities and insights from our scientific leadership.

Insights from Our Experts

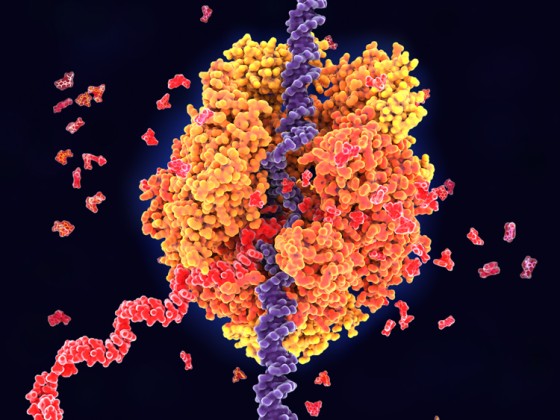

Overcoming pDNA Supply Challenges for mRNA Manufacturing

Mack Kuo, Associate Director of Process Development, Wacker Biotech US, explores the skyrocketing demand for pDNA as mRNA and gene therapy candidates continue to progress from preclinical to early- and late-stage clinical studies. Learn how experts are navigating obstacles such as sourcing challenges, quality issues, scaling difficulties, and lack of standardization. Download the file from the box below.

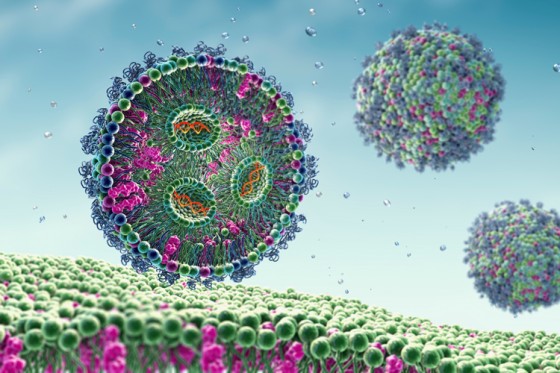

Navigating mRNA Manufacturing with Flexibility and Innovation

Michael Van der Horst, Head of BioProcess Development, Wacker Biotech, shares how Wacker Biotech is meeting the challenge of the complex, multistep processes involved in mRNA–LNP manufacture. Gain insights into how true end-to-end CDMOs can help coordinate raw material supply, scaling, and aligning steps across vendors. Download the file from the box below.

Technology Advances Needed to Drive Future mRNA Growth

Hagen Richter, Head of Nucleic Acids Research, Wacker Biotech, discusses how applications for mRNA are evolving beyond vaccines to therapeutics that treat large populations and personalized therapies tailored to individual patients. Richter also explores the opportunity for innovation in mRNA therapeutic manufacturing, such as continuous strategies and alternatives to pDNA, in vitro transcription, and LNP delivery. Download the file from the box below.

Engage the Experts in Nucleic Acid Therapies

Founded in 1914, WACKER was a key player in forging specialty chemistry advancements throughout the 20th century. In the 21st century, Wacker Biotech has leveraged our wealth of resources, scale, and deep expertise to help advance tomorrow’s life-saving therapies. In close collaboration with universities and research institutions, WACKER’s corporate R&D team of over 200 researchers continuously develops new production platforms and technologies for all types of biopharmaceuticals, including pDNA, mRNA and LNPs. Competitive, outstanding solutions are our trademarks.

Powered by our network of global facilities and commitment to excellence, Wacker Biotech continues to advance nucleic acid therapies, proving highly effective for treating, curing, and preventing diseases for patients worldwide.

Take advantage of this opportunity to shape the future of mRNA therapeutics. Contact us, your reliable mRNA CDMO partner, today for your next mRNA project.

Contact usFeatured Wacker Biotech`s GMP-Certified Facilities

Contract manufacturing plant specializing in the formative production of pDNA and extensive process development services. It has 6 L through 43 L flex-scale single-use bioreactors and a 650 L stainless-steel fermentation vessel, including continuous cell lysis. Corresponding primary recovery and downstream capabilities are available to suit various customer needs.

While today, the San Diego site is primarily dedicated to pDNA development and production, this facility will also offer mRNA process development and analytical capabilities.

Our Halle facility is in the heart of one of Europe's leading life sciences hubs. Halle has years of experience and expertise with the production of recombinant proteins and is Wacker Biotech’s competence center for in-vitro protein refolding, supporting all other sites in development and optimization projects. The site collaborates with the Halle TGZ (technology and startup center) and the many universities, companies, and institutes that innovate at the Weinberg Campus in Halle.

The site is now extended by a dedicated high-end mRNA manufacturing facility in collaboration with the German government as part of the “National Pandemic Preparedness Program”. The plant comprises four independent process lines with high production volume and process design capabilities. In this, pDNA supply, mRNA drug substance, and LNP formulation are enabled by the multipurpose character of this facility. Designated specific capacity is independent and is always available as a full CDMO in the mRNA field by offering services and capacities to customers from early clinical to commercial projects.

Home to our mRNA Center of Excellence, the Amsterdam facility provides capabilities for developing mRNA-based processes and GMP manufacturing of customized mRNA processes.

The site is also a full-service contract manufacturer of biopharmaceutical proteins based on microbial systems and it provides GMP production and manufacturing of biopharmaceuticals, live biotherapeutic products and vaccines for innovative therapies that treat or prevent serious illnesses.

Our Jena plant is a contract manufacturing facility for recombinant proteins and pharmaceutical actives for clinical testing and the commercial market.