Not just for Professionals

Mar 09, 2023 Read time: approx. MinutesMinute

New Silicone Additive for Silicate Paints

Silicate paints and plasters are proving to be a hit with ecologically minded property owners. New silicone additive SILRES® BS 338 makes them easier to use and boosts their storage stability.

Property owners want interior wall coatings that regulate the indoor climate naturally and combat mold growth. Silicate paints and plasters can do this. The problem is, they are not so easy to use: silicate coatings have to be applied quickly and wet-on-wet to obtain an even, attractive finish. “And that is why, unlike professional painters, DIYers have been reluctant to turn to silicate interior wall paints up to now,” says Lenine De Sousa Gomes, marketing manager in the Performance Solutions division of WACKER SILICONES.

Added to which, silicate paints often have poor storage stability. “That’s about to change, because WACKER has developed a new silicone additive called SILRES® BS 338 that can make silicate interior wall paints easier to use and boost their storage stability,” adds De Sousa Gomes.

Silicate paints must be applied quickly and wet-on-wet, which requires a certain amount of practice on the part of DIY enthusiasts.

Postassium Water Glass Binder

Silicate paints and plasters are mineral coating materials that contain potassium water glass, an aqueous solution of an alkali silicate, as a binder. Water glass sets in a chemical reaction called silicification, forming a permanent bond with other silicate materials, such as the fillers in the paint or plaster, or with the mineral surface to be coated.

The set, hard coating contains open pores and so it transmits water vapor. “This means that a silicate interior coating allows virtually unimpeded exchange of moisture between the wall and the indoor air,” explains Martin Sebald, who heads an applications laboratory in the Performance Solutions department of WACKER SILICONES in Burghausen. This breathability is considered to be a key advantage of silicate interior wall paints and one of the reasons why they are popular with ecologically minded property owners.

“Silicate interior paints allow virtually unimpeded moisture exchange between the wall and the indoor air.”

Martin Sebald, Technical Marketing, WACKER SILICONES

Alkalinity Inhibits Mold

Silicate paints and plasters have another advantage: by virtue of their water glass content, they are highly alkaline, often having a pH between 11 and 11.4. This high alkalinity inhibits mold growth. The combination of functions – alkalinity and breathability – acts to prevent the mold from establishing itself on painted walls. Moreover, silicate-based paints are odorless and contain neither solvents nor biocides. They yield attractive matte finishes that are extremely durable. “Silicate interior wall paints and plasters thus create a healthy indoor climate and are ideal for rooms used by people who suffer from allergies,” says De Sousa Gomes.

Increasingly, whenever a decision is made to use silicate coatings, painters are turning to silicate emulsion paints or – especially in recent years – to sol-silicates. Aside from their mineral constituents, these two types of silicate paint contain a polymer dispersion along with one or more additives. The polymer dispersion is typically added in a low proportion, as that ensures the dried coating is highly permeable to water vapor.

The additives are commonly composed of silicones. Their task is to provide the emulsion and sol-silicate paints with the property profile that best meets the needs of painters and plasterers. There are three key considerations here:

- Silicate paints have a fairly high viscosity. Unless they are modified with additives, they will not flow well off the brush or roller and will produce an uneven, streaked finish.

- Their viscosity typically rises sharply in prolonged storage, and that might render the paint unusable.

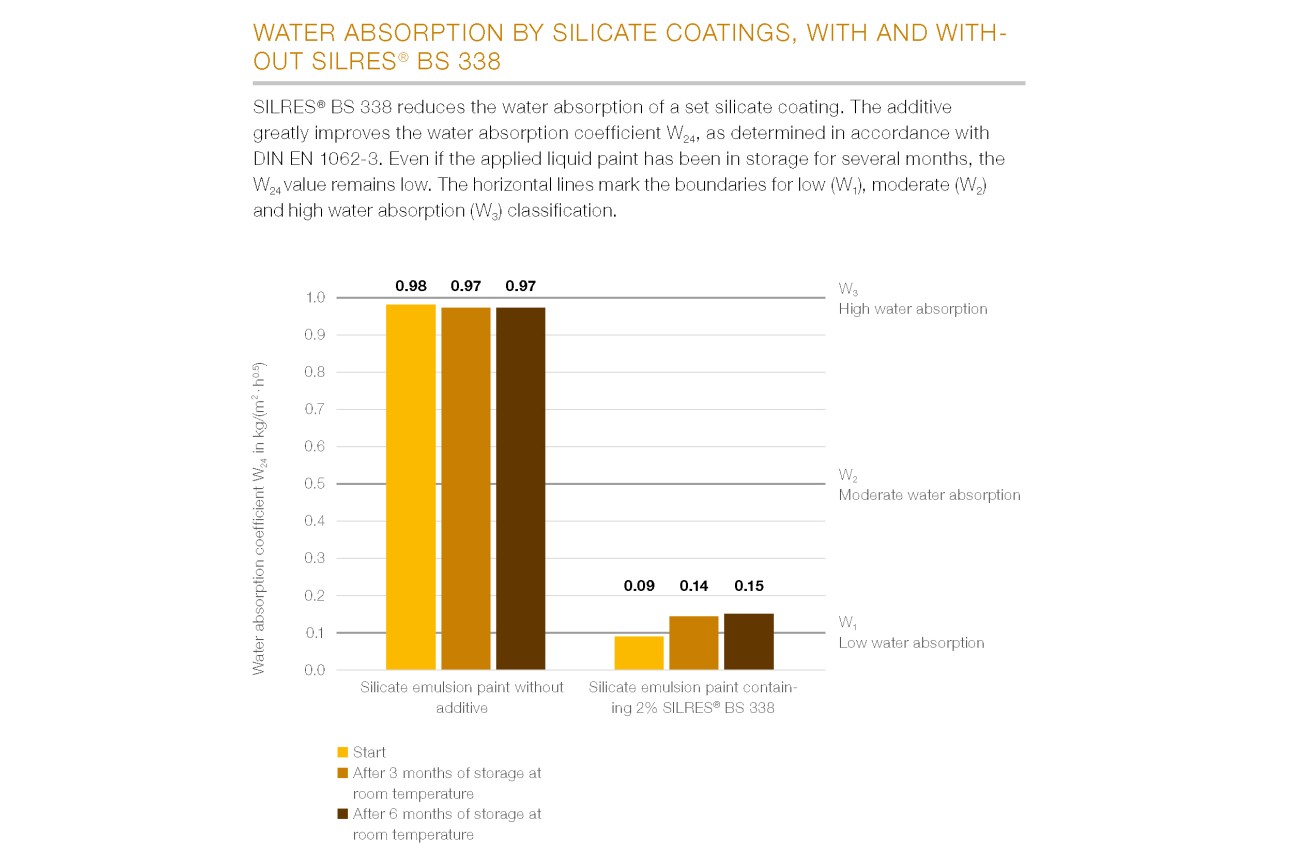

- Silicate systems are hydrophilic by nature, i.e., they absorb water. A suitable additive needs to be incorporated that produces a finish which is both insensitive to water and water-repellent, yet remains fully breathable.

And then there is their high alkalinity to consider. All the ingredients in silicate paints must be able to cope with high pH values during storage. “This has been a key stumbling block for the silicone additives used up to now,” says WACKER applications engineer Sebald. “Many commercial silicone additives are eventually rendered ineffective in alkaline medium.” When that happens, the properties of the silicate paint already start to deteriorate in the unopened original container during storage.

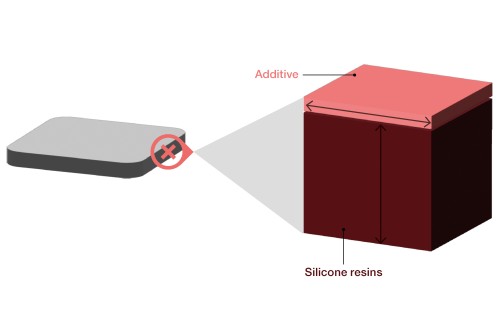

What Silicone Additives can do to a Coating Surface:

Silicone additives (active ingredients):

- Tend to migrate to the surface of the coating

- Partially penetrate the coating

- Their functional groups lead to the creation of a durable chemical bond

Silicone resins

- Are present in the structure of the coating (on fillers, pigments)

Extensive Testing

The remedy is to use SILRES® BS 338. This new silicone additive, developed in the Burghausen laboratory run by Martin Sebald, is an aqueous emulsion of a reactive, functionalized polydimethylsiloxane. “Thanks to its chemical structure, the chosen silicone – which serves as the active ingredient in the additive – can cope with the high alkalinity of silicate paints and thus remains effective for a long time,” says Sebald.

This means that a silicate paint stored for a prolonged period has the same properties as freshly manufactured paint. WACKER applications engineers verified this in extensive laboratory tests on sample formulations of emulsion and sol-silicate paints that were freshly made or had been kept in storage.

11 to 11.4 pH – that’s how alkaline average silicate paints are. This, combined with their breathability, inhibits mold growth.

Like a typical liquid silicone, SILRES® BS 338 contains an active ingredient that has a low surface tension. Its purpose is to ensure that the paint wets the substrate more extensively during application and that it also flows better as a result. The silicone lowers the viscosity of the liquid paint at the same time. The paint is then easier to apply and so even less-experienced users will be able to achieve an even, streak-free finish.

The new silicone additive confers various long-lasting effects on the paint. Durability is provided by the functional groups of the active ingredient, which react chemically with the surfaces of the fillers and pigments as the paint sets. The SILRES® BS 338 also imparts a hydrophobic, i.e., water-repellent, finish to the paint.

This slashes the coating’s capillary water absorption and thus its ability to absorb and be permeated by water – this is just as true for a freshly made silicate paint as it is for one stored at room temperature for three or six months. Measurements of the water vapor diffusion current density according to DIN EN ISO 7783 showed that modification with SILRES® BS 338 does not impair the coating’s breathability, i.e., the paint allows diffusion to occur.

Reduced Absorbency

As interior silicate paints are often applied in two coats, the water repellency also has an effect on the application of the liquid paint: because the first coat is itself hydrophobic, the substrate is now less absorbent and the second coat is less able to penetrate. Consequently, it remains wet for longer. This gives the user more time to touch up any unsightly spots in the second coat. Thus, the additive extends the open time of the second coat.

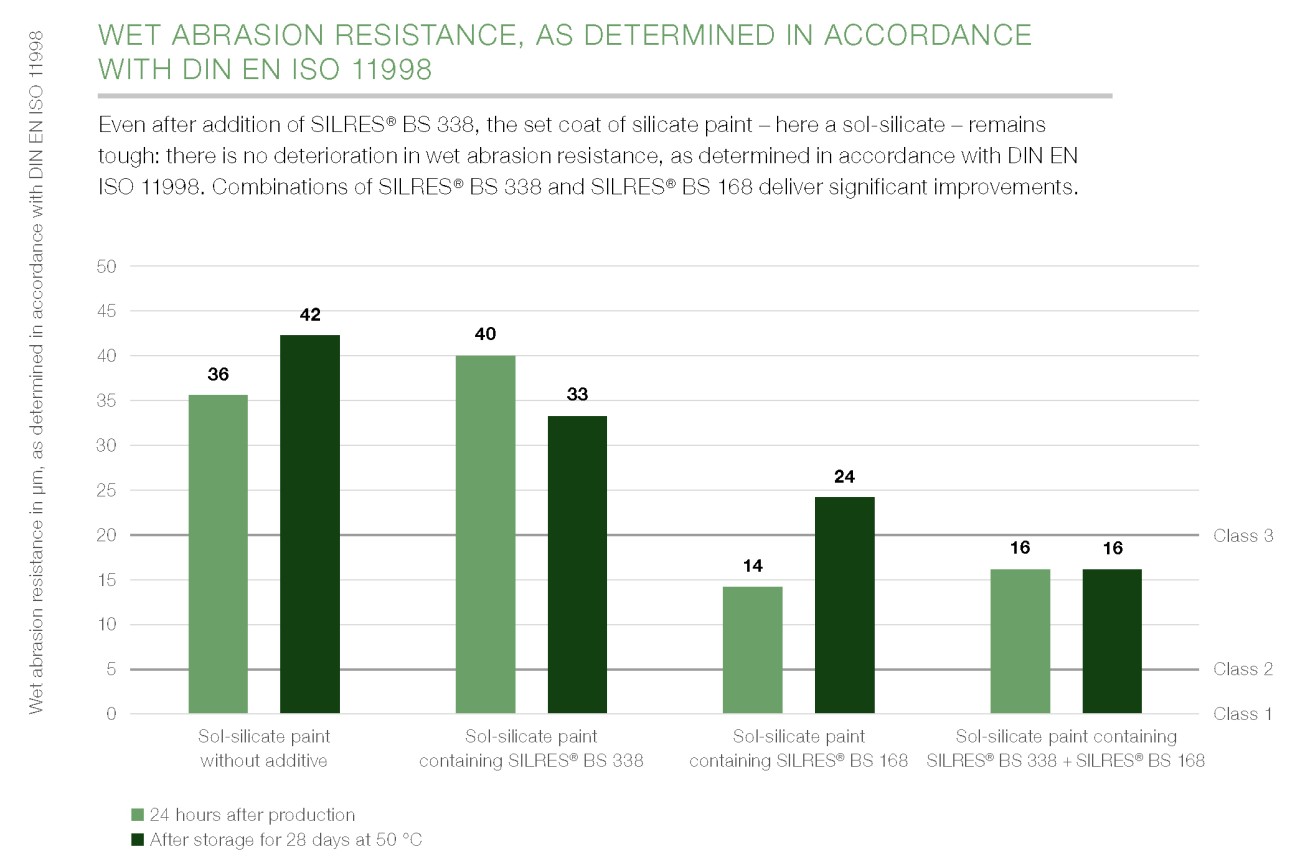

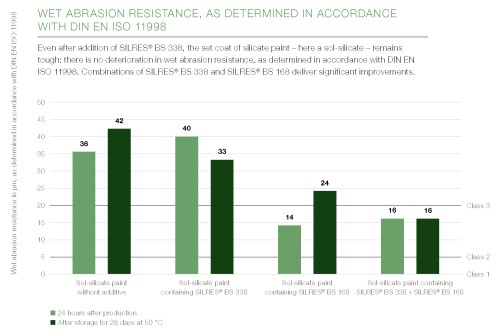

An important property of interior paints is their wet abrasion resistance. It shows how resistant a coating is to scrubbing and is thus a measure of toughness and mechanical strength. Determining wet abrasion resistance involves measuring, in millimeters, the reduction in the thickness of the coating when it is subjected to mechanical stress. The interior paint is then assigned to a wet abrasion class, as set out in DIN EN ISO 11988, on the basis of that loss of thickness. Class 1 indicates the highest toughness, and Class 5, the lowest.

An addition of SILRES® BS 338 imparts a hydrophobic surface to the coating. The applied second coat of silicate paint remains wet for longer and is therefore easier to touch up.

Laboratory tests conducted on a sol-silicate paint modified with the new silicone additive showed that it possessed roughly the same wet abrasion resistance as the unmodified reference paint. “SILRES® BS 338 offers significant improvements in mechanical strength, especially when it is combined with our SILRES® BS 168, a well-known product for adjusting the pH of silicate coatings,” says Sebald, who co-developed this silicone additive for WACKER.

The conclusion reached by WACKER’s construction coatings experts is positive all round: “In SILRES® BS 338, paint makers have an additive that enables them to formulate silicate interior paints that are more stable in storage and much easier to use than conventional silicate paints,” explains De Sousa Gomes. “The new silicone additive is thus paving the way for a new generation of silicate interior paints.”