Good News for the Climate

May 26, 2020 Read time: approx. MinutesMinute

Mass Balance Accounting: Greater Sustainability

WACKER supplies silicone and polymer products that are made entirely from renewable resources. The underlying mathematical method is called mass balance accounting. This calculation is complicated only at first glance.

So far, chemical companies have made most of their products from raw materials based on natural gas, coal or crude oil. Should any of them wish to make products which have the same properties but are made from renewable resources instead, the solution seems obvious. All they have to do is construct a second, identical production plant alongside the existing one. They then make the products using raw materials such as methanol or acetic acid obtained from plant residues – instead of methanol or acetic acid from petrochemical feedstocks. After that, they put a label on the product certifying that what the end customer is buying has come from renewable raw materials and thus is climate neutral.

Trusting that the certificate is reliable is one thing, being certain about its authenticity, however, is another – in this example, radiocarbon-14 dating could ultimately be used to verify whether all the carbon atoms in the product originate from renewable raw materials. This analytical method exploits the fact that carbon atoms in the dead organisms which gave rise to natural gas and crude oil have a low carbon-14 content as a result of radioactive decay. By contrast, living organisms continually assimilate new carbon of higher carbon-14 content from the environment. This carbon, too, follows the law of radioactive decay, but because that is a slow process and because carbon is constantly being formed in the upper atmosphere, it remains at a more or less constant high level

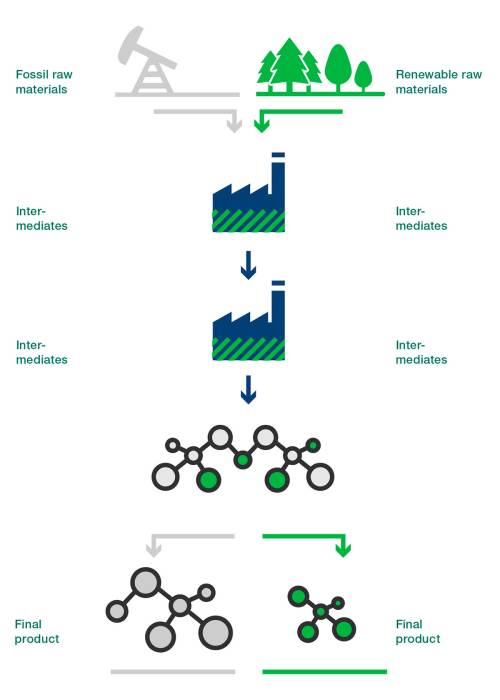

The drawback of carbon-14 dating is the substantial costs associated with constructing and running a second, “eco” plant, which would take time to reach full operating capacity. These considerations can make the “eco” product more expensive and thus less attractive. Consequently, until demand for “green” products is high enough to render a second plant economically viable, the alternative is to process bio-based and fossil-based feedstocks together in the existing plant (see diagram). The initial outcome in that event is a product which is homogeneous in terms of materials and contains carbon atoms from the renewable resources and carbon atoms from the fossil-based feedstocks.

The product is now divided into two fractions. One is given the conventional name and a conventional label while the other is assigned a modified name and a “bio-based” label. This is the approach adopted by WACKER as regards its BELSIL® eco and VINNAPAS® eco (formerly VINNECO®) product lines. The size of the specific “bio-based” fraction is anything but arbitrary. It is chosen to accurately reflect the quantity of renewable raw materials which were input into production. At WACKER, this is verified independently by the South German branch of the TÜV inspection authority.

2,000 °C is the temperature needed to reduce silicon dioxide using coke in a furnace. The coke used is offset by incorporating more biomethanol than is mathematically necessary into production.

It's the Customer That Decides

Were radiocarbon-14 dating to be used for the verification, the conclusion would be that the two product fractions contain the same number of bio-based carbon atoms. However, when the product certified as being bio-based is purchased, a corresponding quantity of renewable raw materials is then included in the production sequence. This situation is akin to what happens when consumers choose a provider of green electricity. The usual regional mix of electricity still comes into their houses. However, through their choice, the provider is then obligated to purchase an equivalent amount of green electricity.

Mass balance accounting also avoids another problem. Not all the starting materials needed by the chemical industry are available from renewable sources. If they were, they would be extremely expensive.

For example, there is no renewable equivalent for the silicon contained in the BELSIL® eco brand of silicones. The reason is that silicon simply does not grow in fields, but instead is obtained by purifying metallurgical-grade silicon. This is a reduction process in which silica is converted with coke in a submerged-arc furnace at temperatures of around 2,000 degrees Celsius.

Mass balance accounting affords the producer the possibility, under a certain proviso, of continuing to use the corresponding fossil-based feedstocks if a bio-based starting material is unavailable or is difficult to source. It allows manufacturers to basically offset the coke used in the production of silicon. And that is the proviso. The quantity of the fossil-based feedstocks used must be offset somewhere else in production by a corresponding quantity of a different, bio-based raw material. That does not mean, however, that producers have to use the exact same quantities of fossil-based and bio-based raw materials in terms of kilograms or liters. What matters is that the calorific values are equivalent, i.e. the quantity of useful heat released when materials are combusted.

The mathematics, then, are only complicated at first sight. Ultimately, mass balance accounting conserves petrochemical feedstocks and reduces the ecological footprint of a given production operation – the more the bio-based product is purchased by buyers, the more pronounced these effects are. This is also good news for the climate.

Buyers of the mass-balanced green product who previously bought the corresponding conventional product have no need to alter their recipes or their conversion processes: chemically, the two products are, after all, identical.

One product, two sources of raw materials: Chemical products from renewable raw materials follow the same logic as green electricity. The product is identical, but purchasing it ensures that production receives an equivalent amount of renewable raw material.