Medical Devices

ELASTOSIL® and SILPURAN® silicone elastomers have a unique property profile that makes them ideal for medical device applications. Three of the many good reasons for using this pure material are that it can be sterilized and offers both excellent chemical and physical resistance without the need for additional stabilizers.

Our ELASTOSIL® and SILPURAN® silicone elastomers each offer the perfect solution for the many diverse, highly sensitive requirements of medical device applications.

The following are some example applications of extrudable solid silicone rubber (HTV) grades, which are primarily used for tubing in the pharmaceuticals and medical industries:

Liquid and solid silicone rubber processed via injection or compression molding can be used for the following applications, among others:

Processing Technology for Medical Applications

Extrusion

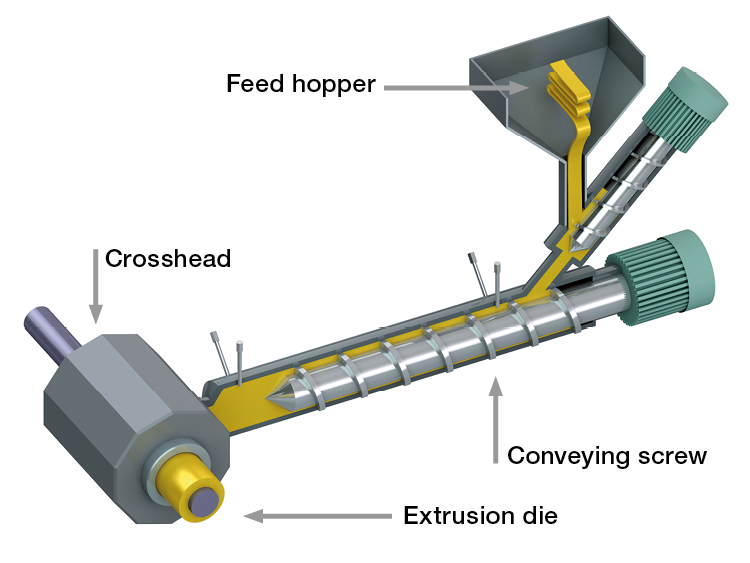

Schematic diagram of an extruder fitted with crosshead die.

This continuous production process involves forcing silicone rubber through a die to shape it, after which the material is cured. The necessary pressure is usually produced by a screw conveyor, in which the material is plasticized, homogenized, compressed and deaerated. This is the process for making medical and pharmaceutical tubing, among other products.

Injection Molding

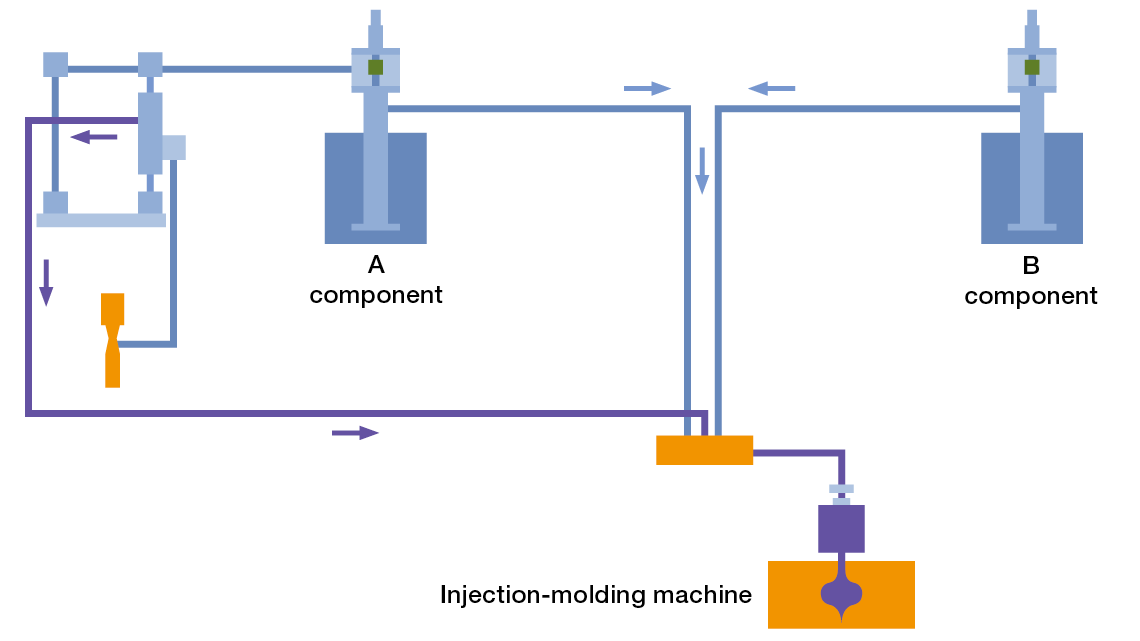

Injection molding is currently the key silicone processing method for producing large quantities of product while meeting high standards of consistent product quality. This method can be used for processing solid and liquid silicone rubber compounds to make products such as gaskets, membranes and valves. We sell liquid silicone rubber as a two-part system (A/B) in 20 kg pails and 200 kg drums. WACKER solid silicone rubber products for molding applications can be purchased as one- or two-part systems; addition- and peroxide-curing grades are available.

Mixing and metering equipment for liquid silicone rubber

ELASTOSIL® eco – Silicone Elastomers That Conserve Resources and the Environment

Through its use of renewable raw materials, WACKER has taken an initial step toward a climate-neutral circular economy – striving as always to increase the proportion of renewables in its production and to expand its line of eco products. The mass balance approach is the tool WACKER uses to achieve this aim.

Brochures

ELASTOSIL® | Silicone Rubber | Health Care | Silicones for Medical Technology

DownloadSILPURAN® | Small and Precise | Silicone Rubber | Health Care

DownloadELASTOSIL® | Liquid silicone rubber | ELASTOSIL® LR 3078 self-adhesive on high-performance plastics

DownloadELASTOSIL® eco | Silicone Rubber | Infosheet

Download