Binders and silicone resins for external thermal insulation composite system (ETICS) applications

Modern external thermal insulation composite systems are multilayer composite materials consisting of insulation panels, mortar, fiberglass mesh, plaster and a coating. Factors that determine ETICS longevity and functionality are the mortars, renders and paints used.

An external thermal insulation composite system (ETICS) is under constant strain: temperature fluctuations, moisture and mechanical influences can compromise its insulating properties and even damage the system as a whole. Powerful adhesive mortars and base coats are key tools for meeting these challenges, as are durable renders and paints.

For construction material manufacturers and producers of paints and renders, our polymeric binders and innovative silicone resins offer solutions for making external thermal insulation composite systems tougher and longer lasting. That results in robust, energy-efficient systems that reduce heating and cooling costs and improve buildings’ carbon footprint.

External thermal insulation composite systems – challenges and solutions

Typical challenges:

This animated video demonstrates how polymeric binders improve the adhesion, flexibility and impact resistance of the cement matrix of an adhesive mortar or base coat.

Our solution:

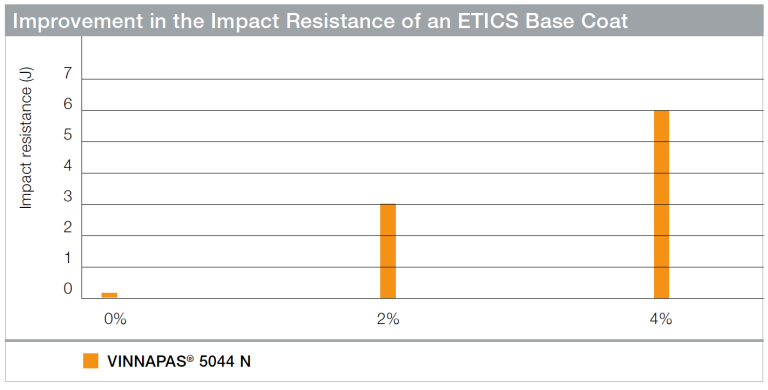

VINNAPAS® polymeric binders ensure excellent adhesion in adhesive mortars and base coats, lending them the flexibility they need to offset the stress caused by temperature changes. The outstanding elasticity and impact resistance of VINNAPAS® formulations provide external thermal insulation composite systems with lasting protection from mechanical stress and reduce crack formation.

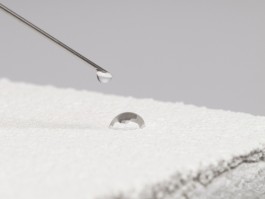

SILRES® BS silicone resins allow manufacturers to create water-repellent, vapor-permeable exterior paints that keep moisture at bay without compromising breathability.

ETICS FAQs

Why are polymeric binders used in external thermal insulation composite systems?

Polymeric binders like VINNAPAS® dispersible polymer powders and dispersions improve the adhesion, flexibility and impact resistance of adhesive mortars and base coats in ETICS applications, where they deliver longevity and resistance to moisture, temperature changes and mechanical stress.

Which VINNAPAS® product classes are available for ETICS applications?

WACKER offers three VINNAPAS® product classes for ETICS applications:

What advantages do SILRES® BS silicone resins confer in external thermal insulation composite systems?

SILRES® BS silicone resins allow manufacturers to formulate weather-resistant exterior paints that combine considerable water-vapor permeability with exceptionally low water absorption. This kind of silicone resin emulsion paint (SREP®) serves as an ideal finishing plaster for external thermal insulation composite systems: it keeps facades dry, does not compromise insulating capacity and improves the potential energy savings of an ETICS over the long term.

Brochures

VINNAPAS® | Construction with External Thermal Insulation Composite Systems

Download