Our system has noticed that you are based in , but the current country setting is . Select country

Press Photos

Please note our terms of use governing the use of press images.By downloading the images from our media database, you agree to these terms of use: Press images may only be used for press purposes (print, electronic media, online) and exclusively in the context of the associated press release and may not be edited. The picture credits (source: Wacker Chemie AG) are mandatory. Images deleted from the media database may no longer be used in the future. If a press photo is used, a copy of the publication or a link to the publication is requested. Otherwise, the copyright information www.wacker.com/disclaimer applies.

SICO Site Jining

Jining-based SICO Performance Material is one of China’s leading producers of specialty silanes. WACKER has held a majority stake in the company since 2022

(JPG, 4.2 MB) Download picture

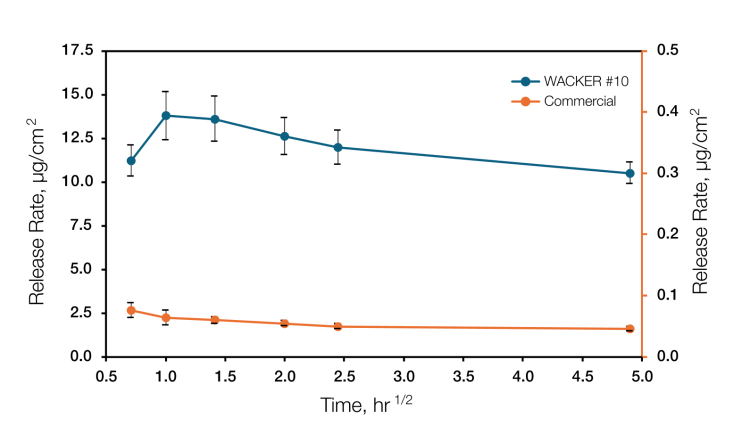

SILPURAN® Release Profile Retinol

WACKER SILPURAN® Release Profile Retinol

(PNG, 57 KB) Download picture