Fabric Care

Protect & Care – A winning team: As additives for different application areas, silicones support and optimize your fabrics in a myriad of different ways. Rise up to the next challenge by choosing a player from our winning team.

Multi-Faceted Silicones with Diverse Benefits for Your Application

Long gone are the days when clothes only had to be clean. Fabrics nowadays have to possess several properties: easy ironing, water repellency, softness and more besides. WACKER’s series of Protect & Care products makes it easy for formulators in the detergents industry to meet these requirements. Innovative silicones added to various end applications provide additional conditioning effects, without building up on the fabric. The best results are produced by a mix of silicones and conventional organic softeners.

We offer an innovative, market-driven range of high-end silicone fabric-care additives that can be used in any combination to meet your needs.

Silicone Products in Fabric Softeners

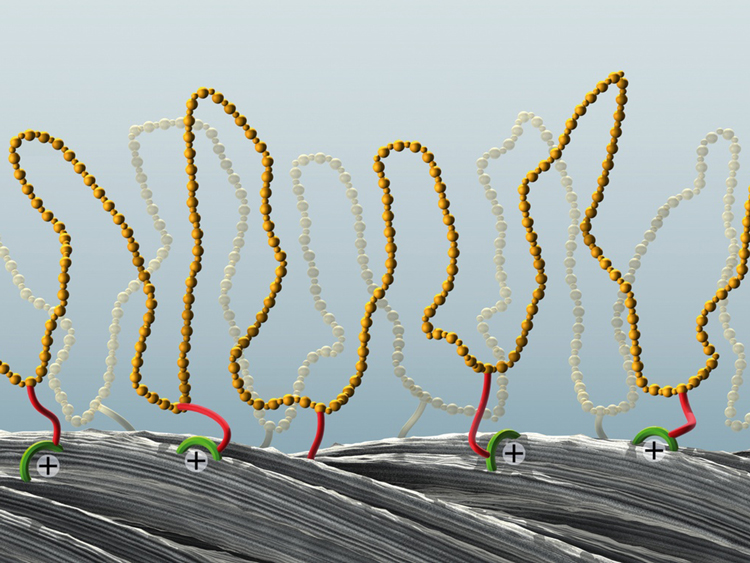

Bereck’s mode of action – The great mobility of the silicone loops enables the treated fibers to readily slip past each other. The very low frictional resistance between the fibers gives the fabrics a silky-soft hand feel; the tactile properties are influenced by the length of the silicone loops.

The active ingredients in fabric softeners reduce friction between individual fibers and between fibers and metal. This counteracts any undesirable effects that may occur during the wash cycle, such as loss of stability. Silicones attached to fibers promotes distribution and leads to excellent lubrication. This is due to the great flexibility of the silicone’s Si-O-Si backbone. Functionalizing the polymers with amine groups, for example, boosts anchorage of the silicones on the fibers.

Fabrics are generally treated with polydimethylsiloxanes, especially those which have amino side groups. The protonated nitrogen atoms of the amine groups of these silicones interact with the negatively charged fabric fibers via electrostatic forces. This ensures very strong anchorage of the silicone polymers on the surface of the fibers. The resulting silicone loops point away from the fibers.

Combination with Esterquat

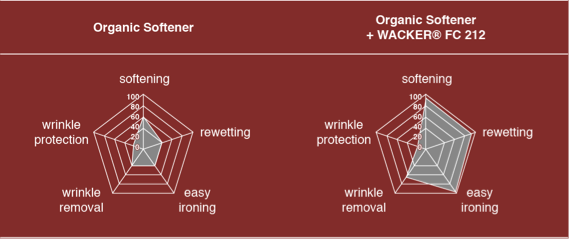

Softness, anti-wrinkle effect, smoothing of folds, easier ironing, remoisturizing

For optimum performance, mixtures of silicones (inorganic component) and esterquat (organic) should be used. Generally, using silicones in conjunction with quaternary ammonium compounds provides effective anchorage on fibers. This is because organic fabric softeners have a good affinity for both the fibers and the silicones. The organic product provides essential softening properties, while also supporting attachment of the silicone products to the fibers. As opposed to that, the silicone product has substantial additional effects, even when present in low concentrations, and so extends the functionality of the fabric softener. The right combination of esterquat-based fabric softeners and silicones imbues formulations with specific effects that are beneficial for use in the wash cycle of washing machines.

Brochures

LIOSIL® | Protect and Care | Silicone Effects for Laundry Care

Download