Industrial Applications

Self-adhesive materials are indispensable in numerous industries. DEHESIVE® release systems from WACKER impart the required release and processing properties to the release liners. Thanks to their consistently high quality, they perform reliably over long periods of time. They are also easy to use and make processing more efficient.

DEHESIVE® release coatings have compelling properties:

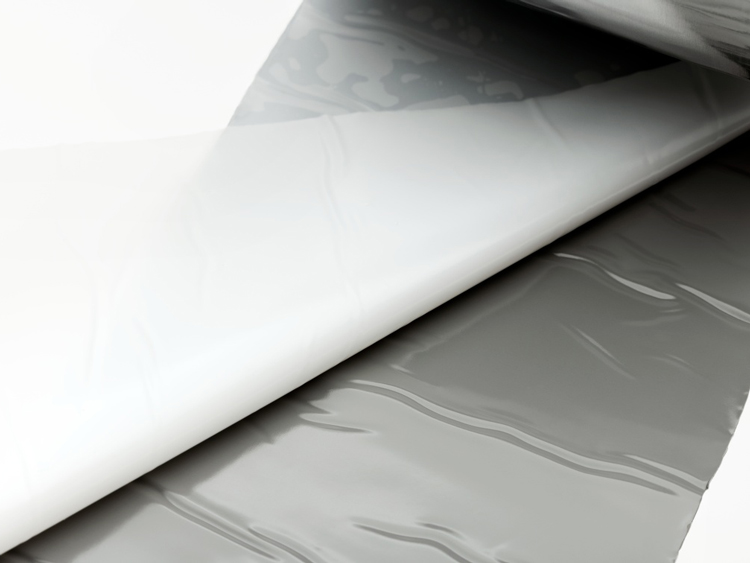

Release Coatings for Composite Materials

Composite materials are used in a myriad of industrial applications. Given their high strength and low weight, they are indispensable in aircraft construction, wind turbines, sports equipment and other sectors. Release liners play a prominent role in handling pre-impregnated components. Coating release liners with DEHESIVE® silicones from WACKER achieves optimal product properties.

Liners coated with DEHESIVE® products from WACKER offer outstanding properties:

Roofing & Bitumen

Bituminous sheets and other roofing materials pose special challenges for release liners. Especially the often high temperatures during processing make releasing the material from the liner difficult. Release liners coated with DEHESIVE® silicones have compelling product properties:

Casting Release Paper

Casting papers face stringent requirements in terms of release properties and appearance. It is essential that the papers allow embossing so that patterns can be transferred to end products such as artificial leather. DEHESIVE® emulsions from WACKER are ideal for casting-paper coating formulations and are compatible with commonly used coating components.