Additives for Extra Special Sustainability

May 26, 2020 Read time: approx. MinutesMinute

Sustainably Attractive

Cosmetics manufacturers use silicone to give their products that special something. And now there’ are additives they can use to achieve something even more special: sustainability. WACKER’s introduction of BELSIL® eco has made it the first manufacturer in the world to produce a line of silicones for cosmetic applications that is based on renewable raw materials.

Just as special effects have become an indispensable part of action movies, the special effects of BELSIL® silicones are likewise a big part of what makes so many cosmetic products successful. They make lipstick kiss-proof by keeping it from rubbing off. They help give eye shadow a seductive, lasting luster. In shampoos and conditioners, they result in silky-soft hair that is easy to comb. And they make creams and lotions feel pleasant and nourishing on our skin. Incorporating even small amounts of these additives – silicone fluids, resins, emulsions or elastomer gels – delivers unique properties that benefit hairstyling and shaving products, as well as sunscreens, foundations, mascara and nail polish.

“Launching BELSIL® eco on the market was our response to requests from the cosmetic industry, where consumers are increasingly demanding sustainable products.”

– Dr. Claudius Schwarzwälder, Marketing Manager Consumer Care, WACKER SILICONES

Even though WACKER manufactures its BELSIL® silicones within an integrated production system that saves energy and resources, these products still have a blemish when it comes to sustainability: the electricity used in their production is generated from fossil resources – natural gas, petroleum or coal – which releases carbon dioxide (CO2). In early 2018, WACKER responded to this situation by complementing its traditional silicones for the cosmetic industry with a line of products requiring no fossil resources whatsoever based on the mass balance method: BELSIL® eco. As independent inspection agency TÜV Süd has confirmed, WACKER produces these silicone fluids by replacing fossil-based materials with the exact amount of renewable raw materials needed for the volume of BELSIL® eco sold.

“Launching BELSIL® eco on the market was our response to requests from the cosmetic industry, where consumers are increasingly demanding sustainable products,” says Dr. Claudius Schwarzwälder, marketing manager for the Consumer Care Products team within WACKER SILICONES. And the success of BELSIL® eco confirms the wisdom of that approach, he believes: “Sales increased eight-fold in the second year after the launch.”

Straw, sugar beet and grass cuttings (from top down): three sources of methanol obtained from renewable raw materials. WACKER takes great care to use only certain grades. Only those grades that are unsuitable for producing foodstuffs are permitted.

Cuttings from a Grass Median Strip

Instead of using methanol synthesized from natural gas, WACKER produces BELSIL® eco with certified methanol from renewable raw materials such as straw, cut grass or sugar-beet scraps. “The agreement we have with our suppliers stipulates that they should only make biomethanol from grades of raw materials that don’t compete with food production,” points out Dr. Klaus Pohmer, head of Global Business and Process Development for Perfomance Silicones at WACKER. The cut grass, for example, comes from the grass median strips of highways which, he notes, is not suitable for feeding animals in any case.

“BELSIL® eco products have a more favorable carbon footprint than silicone fluids based on fossil resources. According to our calculations, each metric ton of biobased silicone fluid saves about 1.6 metric tons of CO2,” Pohmer goes on to explain.

The new BELSIL® eco product line now includes eleven grades, including linear polydimethylsiloxanes (dimethicones), a silicone resin and a gum blend. “That allows us to meet demand for a wide range of applications in the cosmetic industry,” says Schwarzwälder.

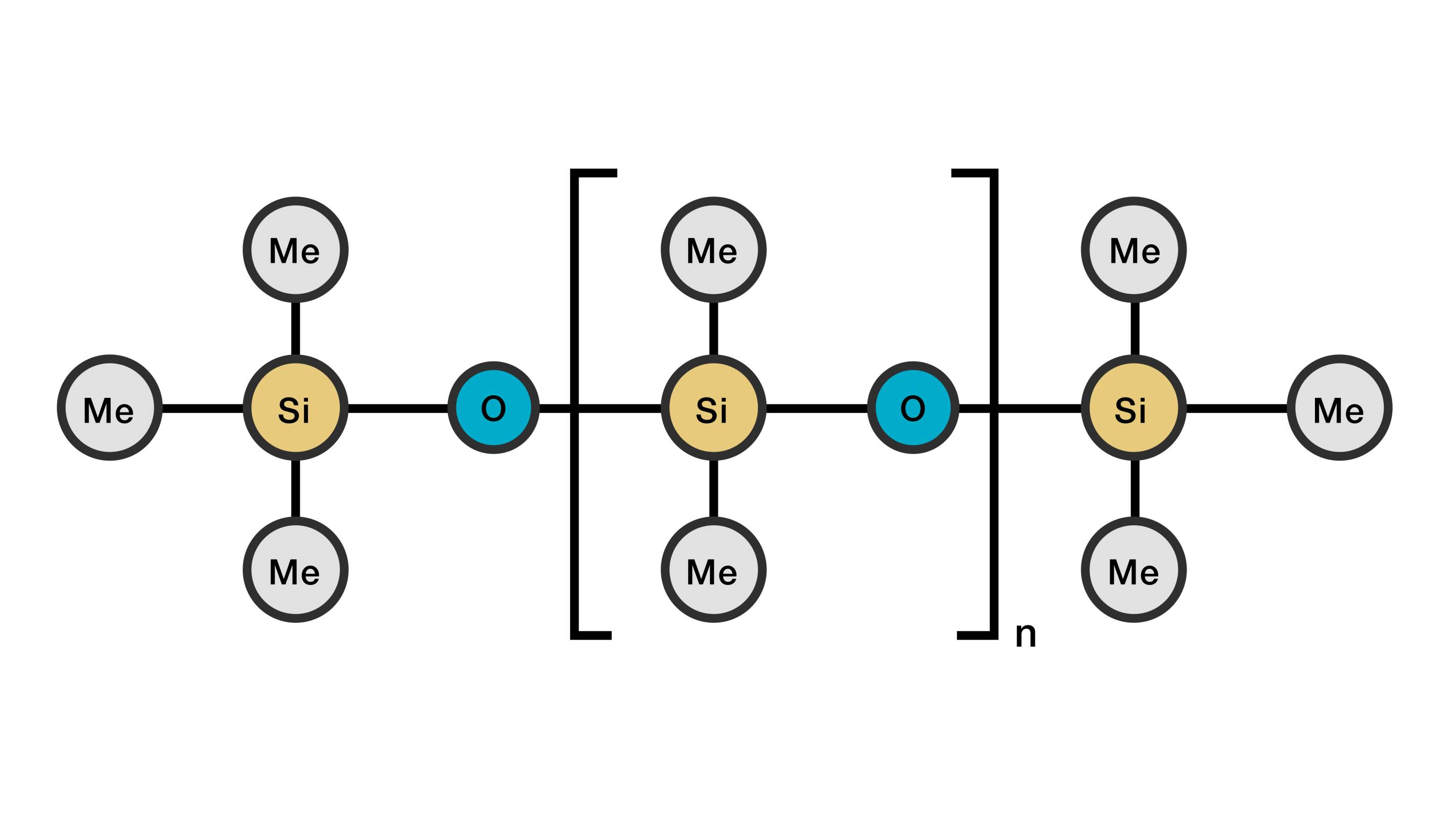

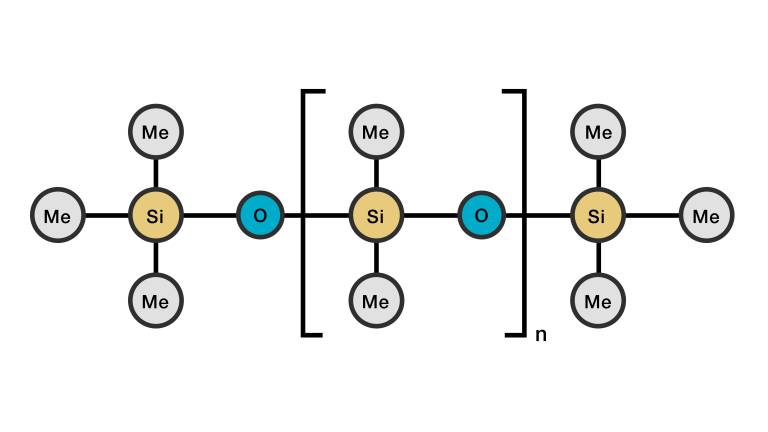

Chemically speaking, BELSIL® eco silicones are absolutely identical to their conventional counterparts. The only difference is that the carbon atoms in the silicone molecules stem from fossil resources in the conventional product line, and from renewable raw materials in the environmentally friendly line. Unlike the carbon atoms, however, the silicon atoms in the silicone molecule are still obtained from conventional, energy-intensive production processes. For this reason, WACKER actually uses more biomethanol in the final product than is theoretically necessary – as a way of more or less offsetting the energy consumed for the reduction of metallurgical-grade silicon, which consumes a great deal of electricity.

“The properties of the two product lines are the same, however. Our customers can replace traditional BELSIL® silicones one-to-one with BELSIL® eco, without having to adapt their formulations,” Schwarzwälder emphasizes. “No other silicone manufacturer in the world has anything like this in its portfolio.”

A Silicone Based Entirely On Non-Fossil Raw Materials.

That makes this green product line attractive to any cosmetics companies that have openly embraced the cause of resource conservation and sustainability.

1.6 metric tons of CO2 can be saved

per ton of silicone fluid from renewable raw materials.

METHYL GROUPS

• Are derived from methanol.

• Fossil-based methanol is replaced by biomethanol.

• Biomethanol is obtained from straw, cut grass, sugar-beet scraps and other plant constituents.

SILICON

• Is derived from quartz sand (non-fossil).

• Quartz sand is converted by charcoal (fossil) to produce silicon.

• The coke obtained from fossil sources is offset by providing the production process with an equivalent amount of biomethanol.

OXYGEN

• The oxygen is obtained from the hydrolysis stage, which uses water.

• Water is a non-fossil raw material.