Seamless and waterproof

Typically, a tent’s weakest point is its outer seams, through which water can penetrate into the interior. A new joining technique from outdoor outfitter VAUDE, based on a solid silicone rubber from WACKER, does without needle and thread altogether. The tent is leak-proof even in heavy rain.

Oct 01, 2018 Read time: approx. MinutesMinute

Seamless and waterproof

Regardless of whether you’re going hiking or on a cycling or camping trip with your children, anyone spending the night outdoors needs one essential piece of equipment: a waterproof tent. Even the smallest leak can quickly make things uncomfortable. It is not the textile layers, but the tent’s seams that are the weak points.

It is common practice to sew the precut fabrics together with needle and thread. However, the needle perforates the textiles, allowing water to penetrate into the interior via the flat-felled seams. That’s why the seams are sealed. Usually, the manufacturer applies sealing tapes to the seams on the inside of the tent.

However, this is not so easy for top-grade tents made of siliconized polyamide fabric. Here, sealing the seams involves a lot of effort for the manufacturer.

VAUDE Sport GmbH & Co. KG, a well-known outdoor outfitter headquartered in Tettnang, southern Germany, recently began marketing a silicone-coated polyamide trekking tent model that uses an adhesive bonding technique without flat-felled seams.

Tent membranes made of siliconized polyamide are bonded together using an adhesive silicone tape. This technique means VAUDE can do without problematical lockstitch seams.

It does not require sealing. The siliconized textile layers are bonded with the aid of an adhesive silicone tape. The bond is absolutely waterproof and exceptionally tear-resistant, and can also be repaired.

VVB-Birzer Flächenschutz GmbH, a silicone processor based in the Bavarian town of Pfaffenhofen, makes the adhesive tape. The tape’s base material is a solid silicone rubber of WACKER’s ELASTOSIL® R plus 4001/40 grade.

A camping tent consists of a flysheet (outer tent), an inner tent and a supporting frame of poles. “The double-wall structure achieves better climatic comfort than a single-walled tent,” says René Bethmann, a textile engineer who works at VAUDE as an innovation manager for materials and production technology.

Longer service life

Like most tent manufacturers, VAUDE is an outdoor outfitter that generally uses polyamide fabric coated on both sides with silicone when making premium tents. The reason for this is the material’s high mechanical strength, as Bethmann explains: “Polyamide fabrics are tear-resistant and the silicone coating further enhances this tear strength. The coating also increases UV resistance – thus extending the polyamide fabric’s service life.”

“Polyamide fabrics are tear-resistant and the silicone coating further enhances this tear strength. The coating also increases UV resistance – thus extending the polyamide fabric’s service life.”

René Bethmann, Innovation Manager, Materials and Production Technology, VAUDE Sport GmbH & Co. KG

By working with siliconized polyamide fabric, tent manufacturers can thus use thin textile layers to produce particularly lightweight tents. This is particularly important for trekking tents, where low weight is key. Sealing the seams, however, is complicated. Unlike the case with less-expensive polyurethane-coated fabrics, where conventional polyurethane seam-sealing tapes can be applied, tent manufacturers have to work with a liquid silicone rubber – and no sealing tape adheres to a silicone surface.

Application of a liquid silicone requires a high level of effort and still involves the traditional sewing of the seams and puncturing of the textile. In addition, the tensile strength at the seams has its limits. That’s why VAUDE was looking for ways to avoid additional sealing of the seams. The outdoor outfitter turned to WACKER. In turn, WACKER’s technical service team established contact with VVB-Birzer.

No need to seal seams

Talks with Christian Birzer of this family-owned business gave VAUDE’s product developers the idea of joining the siliconized textile layers with the aid of a suitable adhesive silicone tape rather than sewing them together. They knew that if they succeeded in creating a tear-resistant and completely waterproof bond, seam sealing would be unnecessary.

The three companies started a joint development project. VVB-Birzer tailored its adhesive silicone tape to VAUDE’s requirements, particularly to allow the bonding of siliconized polyamide fabric cuttings, while WACKER selected the silicone product optimally suited for the adhesive layer, and VAUDE tested the tape’s practical suitability and developed a joining method – which it refers to as siliconized bonding.

Dr. Christian Anger represented WACKER’s technical service in the development project. His investigations yielded ELASTOSIL® R plus 4001/40 – a one-component solid silicone rubber – as the material of choice for the planned application due to its excellent mechanical properties.

“An addition-curing solid silicone rubber, this product chemically bonds to a silicone surface and adheres very well after curing. It is therefore ideal for joining siliconized fabrics,” he says.

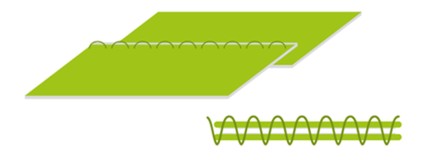

Conventional lockstitch seam:

With this traditional technique, the two layers of fabric are perforated at the seam, making the material less waterproof and reducing its stability. Seams made in this way have to be sealed from the inside.

“If you try to tear the bonded textiles apart, it is more likely that the fabrics will tear than that the joint will fail.”

At high temperatures and under pressure, the product cures very quickly to form a silicone elastomer (see box). In addition, unlike many other silicone elastomers that stem from peroxide-curing solid silicone rubber, the elastomer yields a safe, odorless end product with very good mechanical properties without the need for several hours of postcuring at 200 °C. This was a further selection criterion, as Dr. Anger notes: “A polyamide fabric would not survive postcuring – as experts refer to the several hours of heat treatment – unscathed.”

VVB-Birzer’s part in the development project was to transform the uncured solid silicone rubber that WACKER supplies as cuboid blocks into a tape.

This would be as easy to apply as possible and, after application, result in a bond with good tensile lap-shear strength.

The company supplies the adhesive tape as roll stock. It consists of two layers – a continuous tape of the adhesive silicone layer on a plastic carrier film – wound up into approximately 20-centimeter rolls. The film prevents the silicone layers from sticking together and facilitates application to the fabric; it is peeled off during application and discarded.

Siliconized bonding:

During curing, the adhesive tape made of addition-curing solid silicone rubber bonds chemically with the underlying siliconized polyamide. The joint is twice as tear-resistant as a conventional seam.

The tent producer employs a contract manufacturer, who cuts and joins the fabric pieces and is thus also responsible for applying the adhesive silicone tape. “Until recently, the siliconized polyamide fabric pieces had to be bonded with the adhesive silicone tape by hand. But now we have put in place a partially automated joining process,” says VAUDE’s Bethmann.

The joining process takes place in two separate steps, so it is discontinuous. In the first step, the silicone tape is applied in sections along the cut edge of the lower textile layer – where the two fabric pieces are to be bonded. The carrier film is then peeled off bit by bit, just as the second fabric piece is placed onto the tape and pressed on. This also proceeds progressively in the direction of the line along which the two textile layers are to be bonded. In this way, the contract manufacturer puts all of the fabric pieces together to make the flysheet. This bond is still temporary, however, as the adhesive tape’s silicone has to be cured.

A silicone coating enhances the tear strength of polyamide fabrics even further.

“An addition-curing solid silicone rubber, this product chemically bonds to a silicone surface and adheres very well after curing. It is therefore ideal for joining siliconized fabrics.”

Dr. Christian Anger, Head of Technical Marketing, Rubber Solutions, WACKER SILICONES

Silicone elastomers

Silicone elastomers are rubber-elastic solids based on polyorganosiloxanes. They are obtained from silicone rubber in a process known as curing (vulcanizing). Here, the polymer chains of the organosilicon macromolecules form a three-dimensional network. Silicone elastomers are characterized by a property profile that makes them indispensable in many industrial applications: extraordinary heat resistance, low-temperature flexibility, chemical inertness and biocompatibility.

Silicone elastomers have a strongly hydrophobic, i.e. water-repellent, surface – water droplets simply roll off. Moreover, they do not absorb water and are very good electrical insulators. A typical characteristic is their high resistance to a large number of physical and chemical influences, which is why, unlike organic rubber compounds, they do not age quickly. As a result, their chemical, physical and technical properties remain virtually constant between around -45 and +200 °C; they can also withstand persistent mechanical stress and continued exposure to oxygen, ozone and UV radiation.

Silicone elastomers absorb short-wave UV radiation, which is particularly high-energy. Used in coatings, they are able to protect substrates that are sensitive to UV radiation – such as textiles that are repeatedly exposed to direct sunlight in their application.

Curing in a hot press

Nevertheless, applying pressure makes the fabric pieces hold together well enough to transfer the temporary bond to a hot textile press. This is where the second process step takes place: heat setting. The curing process bonds the silicone tape with the textiles’ silicone surfaces so that they become practically inseparable. Only after this process step does the adhesive bond obtain its end properties.

Laboratory, wind-tunnel and outdoor tests confirm that the adhesive bond is extremely durable: a flysheet produced using siliconized bonding is robust and has a long service life. Here, the properties typical of silicones come into play alongside the high adhesive strength. This adhesive technique makes the joint between the fabric layers absolutely waterproof, permanently preventing rainwater from penetrating the tent via the bonded joints – and making it unnecessary to seal the bonds. The bond is twice as tear-resistant as a conventional flat-felled seam and is also comparatively easy to repair. If, contrary to expectations, a joint should open up years later, the tent manufacturer can re-bond the affected fabric pieces.

With its siliconized bonding process, VAUDE is entering uncharted territory in the outdoor outfitter sector. “All previous attempts to bond siliconized textiles failed,” explains Bethmann, “which is why our expectations were relatively low when we started the development project. But we were pleasantly surprised.” It would not have been possible without the excellent collaboration between the three participating companies, as the textile specialist emphasizes: “Whenever we had a question or problem relating to joining with adhesive silicone tapes, VVB-Birzer was able to give us constructive answers or offer solutions, and WACKER’s technical service team was always on hand with its expertise.”

“Pleasantly surprised”: René Bethmann, innovation manager at VAUDE, holding the tent he helped develop. His tent boasts adhesive silicone seams.

Contact

For more information on this topic, please contact:

Mr. Dr. Christian Anger

Technical Support

Rubber Solutions, WACKER SILICONES

+49 8677 83-86172

christian.anger@wacker.com