Tile in Style

When it comes to tiles, there is practically no limit to the creative potential. Tile designers today experiment with porcelain, glass, natural composites or even synthetics. This is great for architects and interior designers, who have a world of design possibilities at their fingertips.

Still, these materials pose challenges to the installer on site: how do you fix these tiles to walls and floors? In many cases, traditional tile adhesives are not up to the job. Since they were developed for porous materials such as clay or earthenware, they cannot adhere to the smooth, non-porous surfaces of porcelain or glass tiles. This is where modern chemistry comes into play: polymer modification improves the characteristics of tile adhesives, allowing such tiles to be even fixed on wood or on top of old tiles. They thus make possible applications that were hitherto unfeasible. And that is not all: polymer modified tile adhesives can help to combine new design ideas with requirements such as energy efficiency, waste reduction or affordability.

From Cement to Polymer: Tile Adhesives

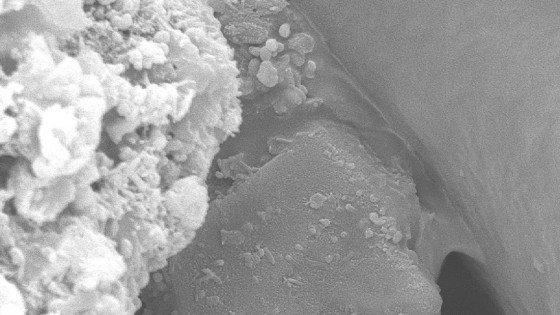

Traditionally, mixtures of sand and cement have been used to install or fix tiles onto walls or floors. With these products, the cement penetrates into the pores of the tiles and bonds the tile mechanically. If the substrate or the ceramic tiles are too smooth, the mechanical bond fails. Adding polymeric binders such as VINNAPAS® VAE dispersions and dispersible polymer powders to the tile adhesive provides enhanced adhesion. The polymer generates a strong and flexible bond between the cementitious mortar, the tile and the substrate. The right type and quantity of polymer are chosen depending on various factors. It is for this reason that modern tile adhesives are pre-mixed as ‘dry mix’ products, only requiring the addition of water at the construction site.

New Tile Adhesives Reduce CO2 Emissions

In general, polymer modification has revolutionized tiling methods. When WACKER developed the first dispersible polymer powders in the 1950s in Germany, it was already obvious how efficient tiling could become. Premixed dry mortars just required addition of water on site and could be applied very thinly to fix the tiles. Switching from the thick-bed to the thin-bed method slashes material consumption to as little as one fifteenth the previous amount. This results in a remarkable reduction of CO2 emissions, because less material is produced and transported. Besides reducing CO2 emissions by saving material, the VINNAPAS® types recommended for ceramic tile adhesives can meet various eco labels and environmental standards in the final mortar formulation.

Tiles Trend #1: Think Big!

New Tile Formats Open Up New Scenarios

The tile-format determines the structure and appearance of the tiled area. Recently the trend has been towards large tiles. This is challenging for the production and transport of the tiles but above all it is a challenge for tiling.

Tiles Trend #2: Showing Off!

Facades with Tiles Have a Great Future

Tiled facades are part of our cultural heritage. In a modern context, they are in vogue again. After all, they are decorative and easy to clean. But how do they fit in with future construction trends, optimized towards sustainability and energy efficiency?

What is Good for the Climate?

Tiles typically used to be applied to mineral structures. But today’s ecofriendly and energy efficient buildings are often finished with external thermal insulation composite systems (ETICS). Here again, the question of adhesion arises. Insulation materials e.g. are mostly organic. Tile adhesives are inorganic. Without polymer modification, no reliable adhesion can be achieved.

An Essential Detail: The Grout

Tiles on facades must face weather, rain, heat, cold, sunlight, acid rain and pollution. And they not only affect the tile itself. The grout also has to withstand the same adverse conditions. Just like the tile, it must withstand, e.g., cleaning, which is conducted by high-pressure cleaners or mechanical force, usually mixed with aggressive cleaning agents. Grouts are made of mineral materials. This often makes them the weak link in the facade. If the grout wears off, water and e.g. salts can penetrate the wall, causing serious damage. Polymer modification of tile grouts offers hydrophobicity and ensure a durable adhesion of the grout on the tile. Thus preventing the grout from delamination.

Interview:

The Materials Sector is Continuously Evolving

What motivates the tile industry? What developments play a role now and in future? We spoke to someone who ought to know: Antonio Carlos Kieling, President of the Brazilian Association of Manufacturers of Ceramic Tiles, Sanitary Ware and Related Products (Anfacer). Brazil is one of the world’s major players in the ceramic tile market, ranking second in both production and consumption. In 2017, 790 million square meters were produced and total sales reached 775 million square meters.

Mr. Kieling, how does Anfacer contribute to the development of the Brazilian ceramic tile industry?

Anfacer plays an important role in the Brazilian ceramic wall cladding industry by promoting integration, seeking common ground, exchanging experiences and other information and, above all, creating an increasingly more favorable environment for business negotiations and market development. The association’s objective is to represent the entire Brazilian ceramic industry at the national and international level from a political and institutional point of view, while also helping to develop marketing and social communication strategies for the ceramic tile sector, facilitating business promotion programs, encouraging exports, aiding standardization of products and processes, offering business defense strategies and monitoring international agreements and treaties. From this perspective, Anfacer plays a fundamental role in the production chain due to its policy of leveraging competitiveness and expanding markets for the ceramic tile industry

Porcelain tiles will continue to have a major impact on the construction market. What changes do you intend to implement?

Porcelain tiles have wide appeal and many different applications as finishing materials. But innovations in this sector are not just the result of such an outstanding cladding material. Sustainability, too, plays a vital role in the ceramic tile sector, with a number of product ranges being designed on the basis of recycled materials. The principal technology used in the production process ensures that quality is maintained, even when surplus production materials are recycled. It is no longer possible to mention emerging markets without touching on sustainability. Another current innovation is digital printing in Full High Definition.

"Sustainability, too, plays a vital role in the ceramic tile sector, with a number of product ranges being designed on the basis of recycled materials."

Antonio Carlos Kieling

We are currently seeing a great deal of indoor porcelain tile applications. Will there be new ones in the future?

Porcelain is a very versatile and resistant product, currently used on the outer areas, or facades, of buildings. The industry has invested a lot of time and money into the technology, functionality and aesthetics, including that of large-scale tiles, which require fewer joints. Another important innovation is the application of digital printing to this product, making it possible to print designs and textures directly onto the porcelain. The product range has therefore increased, for both outdoor and indoor applications. For example, current tile ranges offer more than 300 color combinations.

Are there any obvious omissions in terms of current applications?

The materials sector is constantly evolving. Thanks to advances in quality and technology, there are now far fewer challenges to tile installation, despite the availability of tile units of varying thicknesses, mixtures of different materials, multiple sizes and numerous colors, patterns and textures. However, if I had to name an area that still has plenty of room for improvement, I would say coating materials for facades – a market that still has scope for growth and development.

Curious About Our Solutions for Tile Adhesives and Tile Grouts?

WACKER offers a wide range of products that help you to formulate the perfect adhesive. Find all the details in our product section!

Show Products