Earth Overshoot Day 2020 - Our Commitment to Resource Conservation

Earth Overshoot Day occurs on August 22, the date when humanity’s demand for ecological resources and services exceeds what Earth can regenerate in 2020. In other words, simply to maintain its lifestyle at current levels, humanity would need to consume the equivalent of 1.75 Earths.

This makes it all the more vital to advocate for greater responsibility in the management of resources. WACKER is on board with its own valuable contribution:

Interview: Dr. Kirill Rachinskyi, Waltraud Haas and Daniel Hofstetter from the Services & Processes Department analyze sustainability in the WACKER supply chain.

1. How is WACKER contributing to sustainable resource management in the supply chain?

“In 2015, WACKER joined the Together for Sustainability (TfS) initiative with a view to measuring and improving both its sustainability performance and its management of resource sustainability in the supply chain. This chemical industry program seeks to develop and adopt a global, standardized approach to reviewing and improving sustainable practices in the supply chain. Aside from greater transparency in the supply chain, we are increasingly talking to our suppliers about realizing potential improvements in resource management.

2. How does WACKER ensure that its suppliers comply with requirements?

“WACKER expects its key suppliers to provide proof of sustainable practice, such as an EcoVadis assessment or a TfS audit. At the moment, these cover 92% of the procurement volume of our key suppliers. A minimum score of 45 points out of 100 must be obtained in an EcoVadis Assessment and a TfS audit must not identify any major or critical deviations. Should the results fail to meet our expectations, our buyers work with the supplier to develop corrective measures that will boost the sustainability performance. The results of these sustainability evaluations feed straight into WACKER’s annual supplier evaluation which gives the supplier feedback on his performance over the previous year. We also monitor current news and events and follow up on any negative sustainability news that involves our suppliers.”

3. How does WACKER tackle the issue of conflict minerals?

“Just how seriously we take this responsibility is reflected in the regular reviews and analyses that we conduct of the raw material sources. Every year, for example, we use the latest conflict minerals reporting template (CMRT) to ensure that the minerals we procure are sourced only from legal mines that are compliant and are also operated under fair employment conditions.”

Cutting Consumption of Fossil Resources is the Main Objective

Supply chain management aside, WACKER conserves resources through its integrated production system and its adoption of the mass balance approach to boosting usage of renewable raw materials.

Through the highly integrated production systems in operation at its major sites in Burghausen, Nünchritz, Charleston and Zhangjiagang, WACKER has devised a unique product and production strategy that conserves both energy and resources by closing production loops. This production-integrated environmental protection takes the following forms:

- Integrated energy solutions based on the principle of reusing the generated waste heat in downstream chemical processes.

Examples: Generating steam from waste heat, preheating feed water for deionized (DI) water production. - Integrated material systems in which byproducts generated in a given process are incorporated into material loops to conserve resources, either by being treated and fed back into that process or by serving as raw materials for other processes.

Examples: Integrated hydrochloric acid and silicon production, integrated acetic acid production

We are constantly working to optimize the integrated production system. We are also exploring ways to extend the circular economy such that materials from our customers, partners and suppliers are moved around in a loop with our own WACKER materials.

Some 67 percent* of products from WACKER are based on inorganic raw materials (quartz sand is the chief raw material for silicon metal); 26 percent* are based on organic raw materials (ethylene and methanol, just like their downstream products acetic acid and vinyl acetate). Even the renewables content in our BIOSOLUTIONS products is almost 50 percent*. By additionally incorporating renewable raw materials via the mass balance method , we are driving down consumption of fossil raw materials and greenhouse gas emissions within our fully integrated production system (“Verbund”).

*Based on sales

Tools for Analyzing Sustainability Aspects Along the Supply Chain

At WACKER, we have integrated the protection of resources into many other processes:

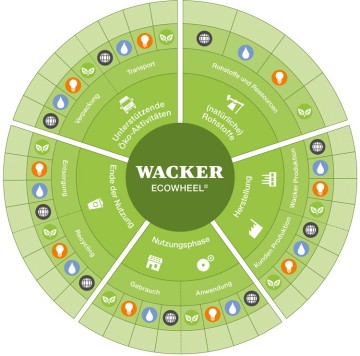

The WACKER ECOWHEEL ® is a tool that helps us to reveal positives and negatives over a product’s full life cycle and provides a sound foundation for the more elaborate PARC evaluation conducted as part of the WACKER Sustainable Solutions project.

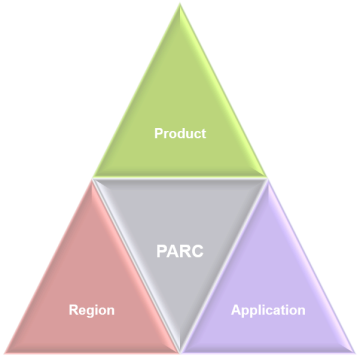

The WACKER Sustainable Solutions project seeks to evaluate the product portfolio so as to identify opportunities and risks relating to the sustainable aspects of our products. The evaluation covers the product’s full life cycle, its specific application, and regional specifications. It starts by classifying products or product groups into what are termed PARCs. PARC stands for

- a product

- an application, and

- a region

- in combination.

All products are rated for their compliance with sustainability criteria. .

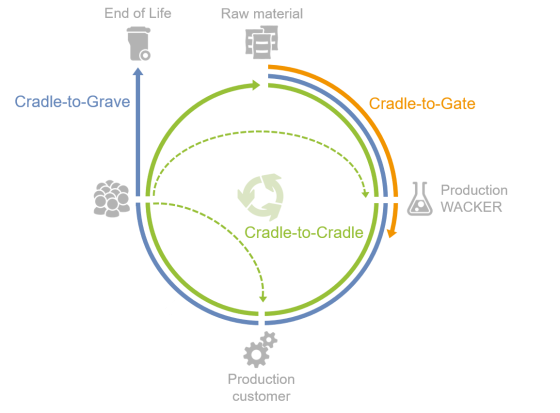

At WACKER, we conduct life cycle assessments to determine the environmental impact of a product over its life cycle. The results of these assessments are listed under standardized impact categories. These include: global warming potential, resource consumption, ozone depletion potential and acidification potential. The goal of life cycle assessments is to anchor life-cycle thinking more firmly at WACKER.

Specific examples of resource protection

WACKER supplies the solar industry with ultrapure polysilicon, thus helping to reduce the amount of CO2 otherwise produced during power generation. As one of the main global suppliers of polysilicon for the manufacture of solar modules, we support the switch to renewable energy sources. The solar power from solar installations for which we supplied the polysilicon in 2017 will save some 466 million metric tons of CO2 over the course of the installations’ lifetime (30 years) relative to the current national energy mix. (For comparison: this is almost equivalent to the annual CO2 emissions of Brazil, which were around 493 million metric tons in 2017). This calculation is based on the “Addressing the Avoided Emissions Challenge” standard issued by the WBCSD (World Business Council for Sustainable Development).

In the construction sector, modern polymeric binders are cutting down on the use of sand and cement and thus helping to conserve resources.

Find out more about the sustainability strategy SustainaBalance® and the roadmap to 2030 at WACKER!