Productronica 2018: WACKER Presents New Multi-Use Silicone Adhesive with High Strength

Shanghai, Mar 14, 2018

WACKER will present the new silicone adhesive ELASTOSIL® RT 704F at this year’s Productronica China. A one-part, heat curing black adhesive, ELASTOSIL® RT 704F features good flowability and high tensile strength. It is a multi-use silicone adhesive for automotive, electronics, lighting and industrial applications. WACKER will also present SEMICOSIL® 961 TC, a heat-conducting silicone gap filler for the electronics industry, and LUMISIL® UV, a series of UV curing silicone for optical bonding. Productronica China 2018 takes place in Shanghai from March 14 to 16.

ELASTOSIL® RT 704F is a carbon-black silicone adhesive with self-levelling properties. The one-part product is solvent free and easy to use. It cures in ten minutes at 140ºC and in two minutes at 200 ºC. After curing, its tensile strength is as high as 5.0 N/mm2. ELASTOSIL® RT 704F features excellent adhesion with many substrates without primer. It is not only used as multi-use silicone adhesive for automotive, electronics, lighting and industrial applications, but can also be used to mount and seal lids and housings, baseplates, connectors, ABS, controllers, inductors, and transformers in the solar power and lighting industry.

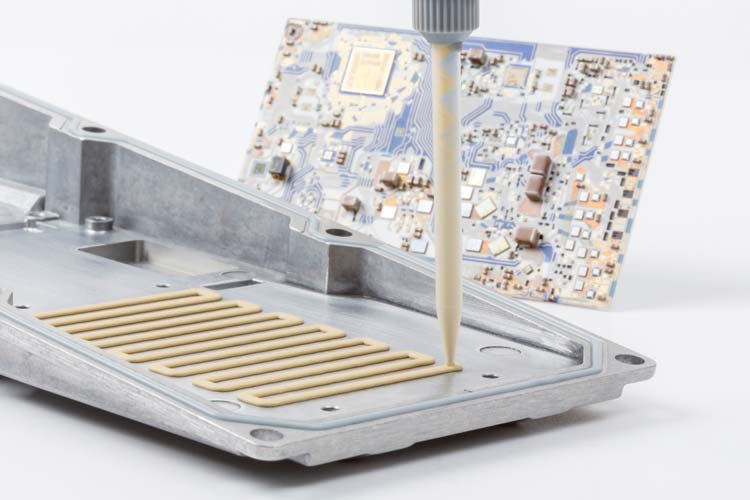

During Productronica China 2018, WACKER will also present SEMICOSIL® 961TC, a highly filled, two-part silicone rubber that cures at room temperature via a platinum-catalyzed addition reaction to form a soft silicone elastomer with a tacky surface. The cured rubber achieves a thermal conductivity of 2 W/mK and, at the same time, is electrically insulating. SEMICOSIL® 961TC ensures optimum heat transfer from the electrical circuit to a heat sink. In practice, the thermal conductive gap filler is applied on a heat sink, with the circuit board covered directly or by a vacuum connection process. Once pressed into place, the thermal conductive gap filler forms a continuous film that conforms snugly to the surfaces of the two joining parts, and fill even the tiniest irregularities of the substrate surfaces. Moreover, the continuous film also maximizes the contact area and speeds up the heat transfer.

WACKER’s offering at Productronica also includes the LUMISIL® UV product series, a two-component, UV-curing silicone based on optically clear resins. High transparency, low shrinkage, low E-modulus and a low dielectric constant – all these properties make LUMISIL® UV suitable for vehicle-mounted navigation, industrial control and outdoor screens. Eliminating side curing effects in the shadow areas which may impair proper bonding of the component, the LUMISIL® UV not only ensures a reliable bonding of the display, but also simplifies the bonding process and enhances production efficiency significantly. The series includes several product grades. Viscosities vary from 2,000 to 45,000 mPa*s which matches the requirements of all production processes and equipments used in the industry.

Contact

Wacker China

Media Relations & Information

Jessica He

Phone:+ 86 21 6130 2588

Email jessica.he@wacker.com

Send Message