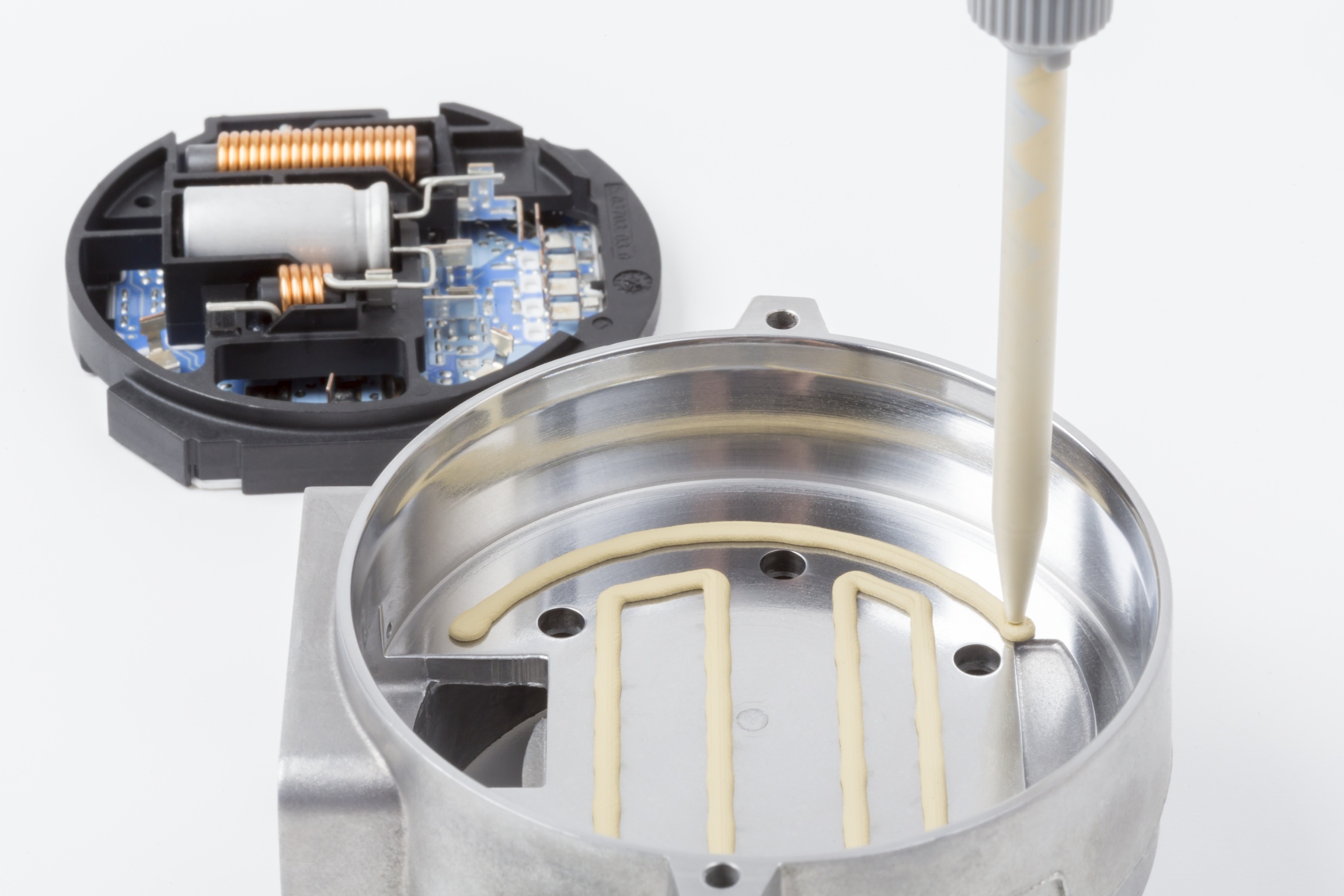

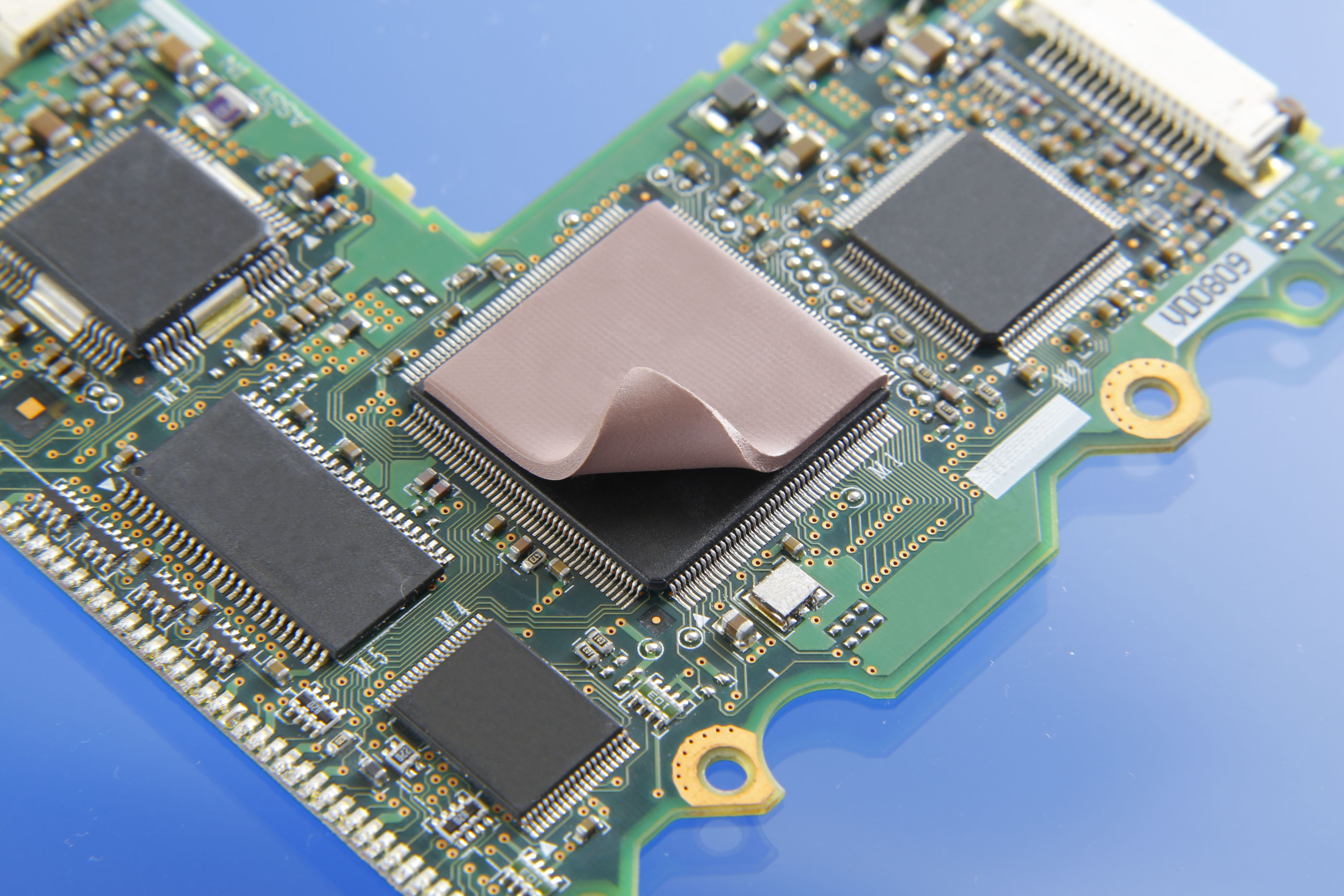

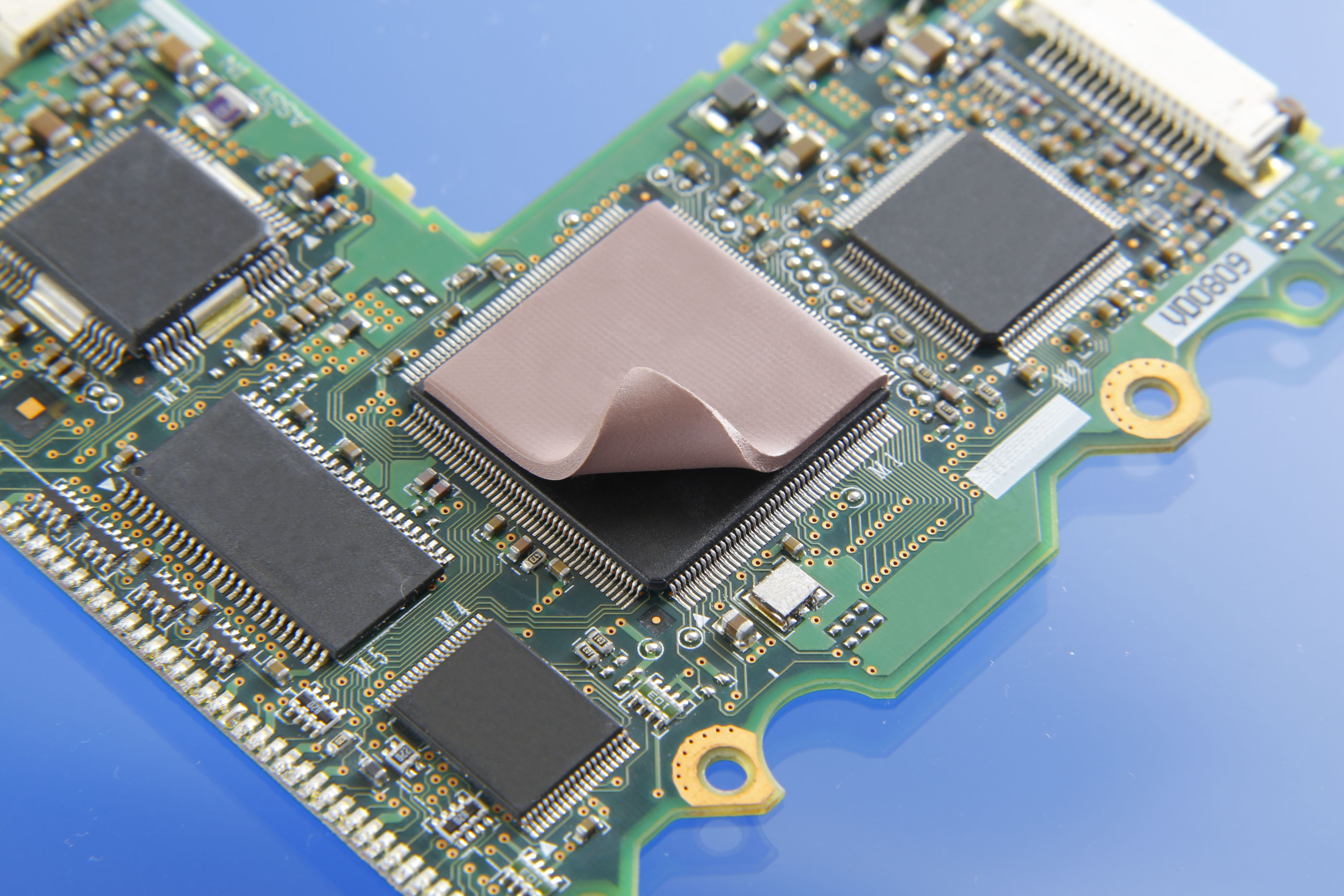

WACKER and Fuji Polymer Industries are leading manufacturers in the field of silicone-based thermal interface materials (TIM) for industrial applications, but have different product offerings. Whereas WACKER, as a silicones producer, supplies non-crosslinked paste-like silicones in the form of gels, adhesives, sealants or encapsulants for liquid metering, Fuji Polymer Industries produces ready-to-use silicone elastomer parts, such as contact mats, films and pads, for electronics and automotive component manufacturers.

Fuji Polymer Industries and WACKER will now intensify and broaden their collaboration. “Both companies are experts and possess unique knowledge, how to formulate and process thermally conductive silicones: WACKER in the field of liquid systems, Fuji Polymer in ready-to-use components,” says Christian Gimber, head of Engineering Silicones at WACKER SILICONES. “In future, we will intensify our collaboration in order to be able to develop innovative materials that meet the constantly growing demands of the electronics and automotive industries. The collaboration we have now embarked on will go far beyond this expo.”

At the upcoming 11th International Automotive Electronics Technology Expo in Tokyo, Fuji Polymer Industries will already exhibit the first fruits of this collaboration. “Electronic devices and batteries generate a great deal of heat that impacts their functionality and service life and can lead to serious faults. Efficient thermal management is therefore increasingly essential in many applications, such as in consumer electronics and electric vehicles,” says Gimber. For improved thermal management of components, the industry is increasingly turning to heat-dissipation materials, continues the WACKER manager. “Our thermally conductive silicones can be processed very efficiently, but that is not the only benefit of silicones. They also meet the stringent and rising safety and reliability requirements imposed by the electronics and automotive industries.”

Fuji Polymer Industries, too, will benefit enormously from the development partnership. “We have been very much looking forward to this collaboration which is very important for us. WACKER’s technical expertise is an invaluable resource and is extremely helpful when developing new products,” says board member Mitsuhiro Fujimoto. Fuji Polymer Industries will also use WACKER’s “Based on ELASTOSIL®” logo for branding its high end silicone based thermal interface materials. “This co-branding is another significant benefit for the company in terms of quality awareness,“ emphasizes Fujimoto. “The partnership with WACKER is therefore a genuine win-win situation for us and fills us with a great deal of pride.”