Press Photos

WACKER provides you with free photos for editorial purposes. Please send us a screenshot or a copy of the printed publication. Use the selection box to find photos of the Group and its products, as well as their applications. Click the desired category to receive an overview with thumbnails. You can then order the photos you need via e-mail.

Category

Reset perimeterClick the desired category to receive an overview with thumbnails.

You can then order the photos you need via e-mail.

Fig. 02: 3D_Silicones_Object

A silicone part made by 3D printing. WACKER, the Munich-based chemical group, has developed a process that enables the printing of three-dimensional silicone objects for the first time. The process is ideal for numerous industrial sectors. It opens up completely new opportunities for developing products in the automotive, medical, household-appliance and lighting industries. Now prototypes with complex geometries can be produced quickly and flexibly, without expensive tools. In the same way, it is possible to produce small series and spare parts that have to be continuously modified to meet changing requirements.

Order photoFig. 01: 3D_Silicones_Printing

Current 3D printing technologies use glass, metal, plastic, synthetic resin or ceramics as starting materials. What was missing was a process for silicone elastomers – that is, until now. WACKER has developed a 3D technology that makes it possible to build three-dimensional silicone objects for the first time.

Order photoPilot Coater - DEHESIVE® SFX line

WACKER pilot coater in Burghausen. This is where the solvent-free silicone polymers of the new DEHESIVE® SFX line were developed. At its coating center, WACKER lends support to leading label and paper coating companies from all over the world.

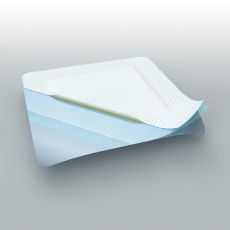

Order photoRelease coatings - DEHESIVE® SFX

Release coatings with silicone polymers of the new DEHESIVE® SFX product family are ideal for high-speed labeling machines. The new silicone grades are very cost-efficient. With their help, the proportion of platinum catalyst in the coating system can be lowered by up to 60 percent compared to conventional silicone systems.

Order photoSilicone Adhesives SILPURAN®

At the EWMA Conference 2016; WACKER is presenting SILPURAN® 2114, SILPURAN® 2122 and SILPURAN® 2142. The silicone adhesives offer relatively high adhesion, as is required for traditional adhesive plasters, dressing retention materials and other traditional wound dressing products.

Order photo