Press Photos

WACKER provides you with free photos for editorial purposes. Please send us a screenshot or a copy of the printed publication. Use the selection box to find photos of the Group and its products, as well as their applications. Click the desired category to receive an overview with thumbnails. You can then order the photos you need via e-mail.

Category

Reset perimeterClick the desired category to receive an overview with thumbnails.

You can then order the photos you need via e-mail.

Vaccines: Fill & Finish

From development to dispensing: at the Amsterdam site, vaccines can be dispensed into their final packaging for shipment to the customer. The vials then undergo one last quality check (photo: WACKER).

Order photoVaccines: Fermenter

In stainless steel tanks known as fermenters, bacteria at Wacker Biotech produce the desired active substances (photo: WACKER).

Order photoVaccines: Lab

Before the large-scale production of a vaccine can begin, the first step is to develop the production process in the lab (photo: WACKER).

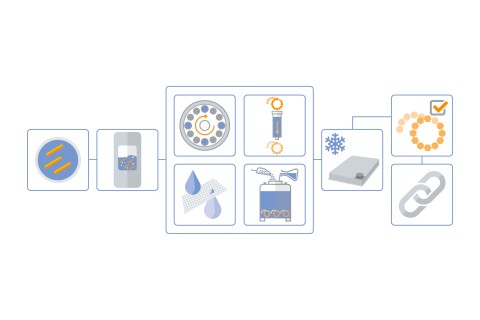

Order photoProducing a Conjugated Polysaccharide Vaccine

(Illustration: WACKER)

Order photoWacker Biotech Dr. Susanne Leonhartsberger

Dr. Susanne Leonhartsberger has been the managing director of Wacker Biotech GmbH since 2017, and, in her capacity as the head of the Biopharmaceuticals business line, is responsible for WACKER’s biologics business. “What especially motivates me is that we’re providing innovative medications for sick people all over the world – and that’s how most of us feel,” the biologist observes. (Photo: Wacker Chemie AG)

Order photo