Foamed milk is as intrinsic to cappuccino as bubbles are to champagne. Vegans, who favor plant-based milk substitutes, can now also enjoy a full-bodied, creamy foam. This is made possible by cyclodextrins based on plant starch.

Nov 30, 2020 Read time: approx. MinutesMinute

A Perfect Take on Milk Foam

Not all milk foam is the same. In many large cities, you can now find barista academies, where café owners, or even just ordinary individuals, can learn how to make aromatic coffee along with the perfect milky topping. Large coffee and fast-food chains in turn have their own training facilities and laboratories in order to impart the necessary expertise as regards cappuccino, latte macchiato, etc. to their employees and to work on optimum formulations. The milk should be no hotter than 65 to 68 degrees Celsius and the steam nozzle should always sit one to two centimeters below the milk’s surface – these are just two of a whole set of rules that a good barista should follow.

Not only the sweet, creamy taste is important, so is the appearance of the topping – our eyes evidently savor a latte macchiato or cappuccino, too. That’s why more and more cafés and espresso bars are making an effort to decorate these coffee specialties with milk-foam images for their customers. Professional baristas even compete in this so-called “latte art” at international contests.

But what about soy, almond or oat milk? Many consumers now prefer these plant-based alternatives to cow’s milk, either because they wish to reduce their consumption of animal products partly (if they are flexitarian) or completely (if vegan), or because they are lactose-intolerant or are allergic to cow’s milk protein.

The foam lasts considerably longer – retaining the coffee’s appealing look in the cup for much longer.

Dr. Ulrike Fischer-Nägele, food laboratory head, WACKER BIOSOLUTIONS

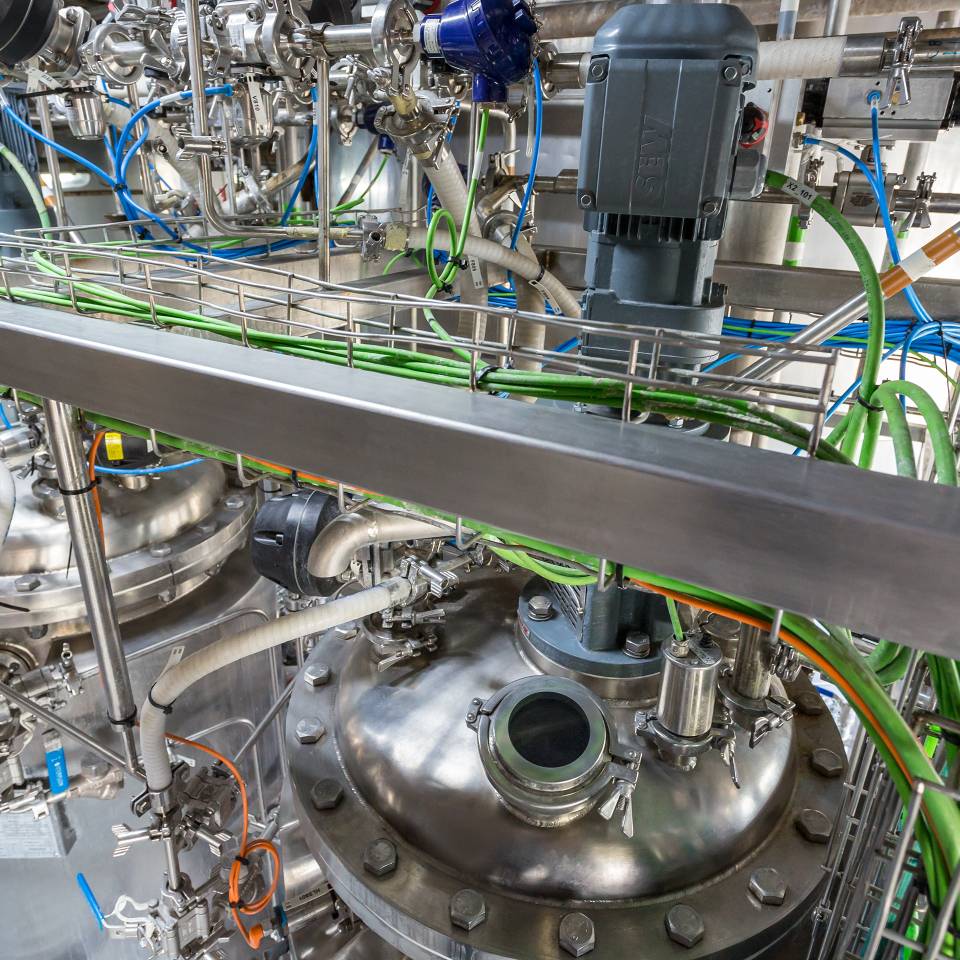

A look inside the food lab in Burghausen: technicians use this test setup to measure foam firmness.

Although some plant-based milk alternatives can be foamed, experienced baristas know that it is more difficult to produce great latte art with them. “Here, the foam’s stability and durability are the deciding factors,” emphasizes Dr. Ulrike Fischer-Nägele, head of the WACKER BIOSOLUTIONS food laboratory in Burghausen.

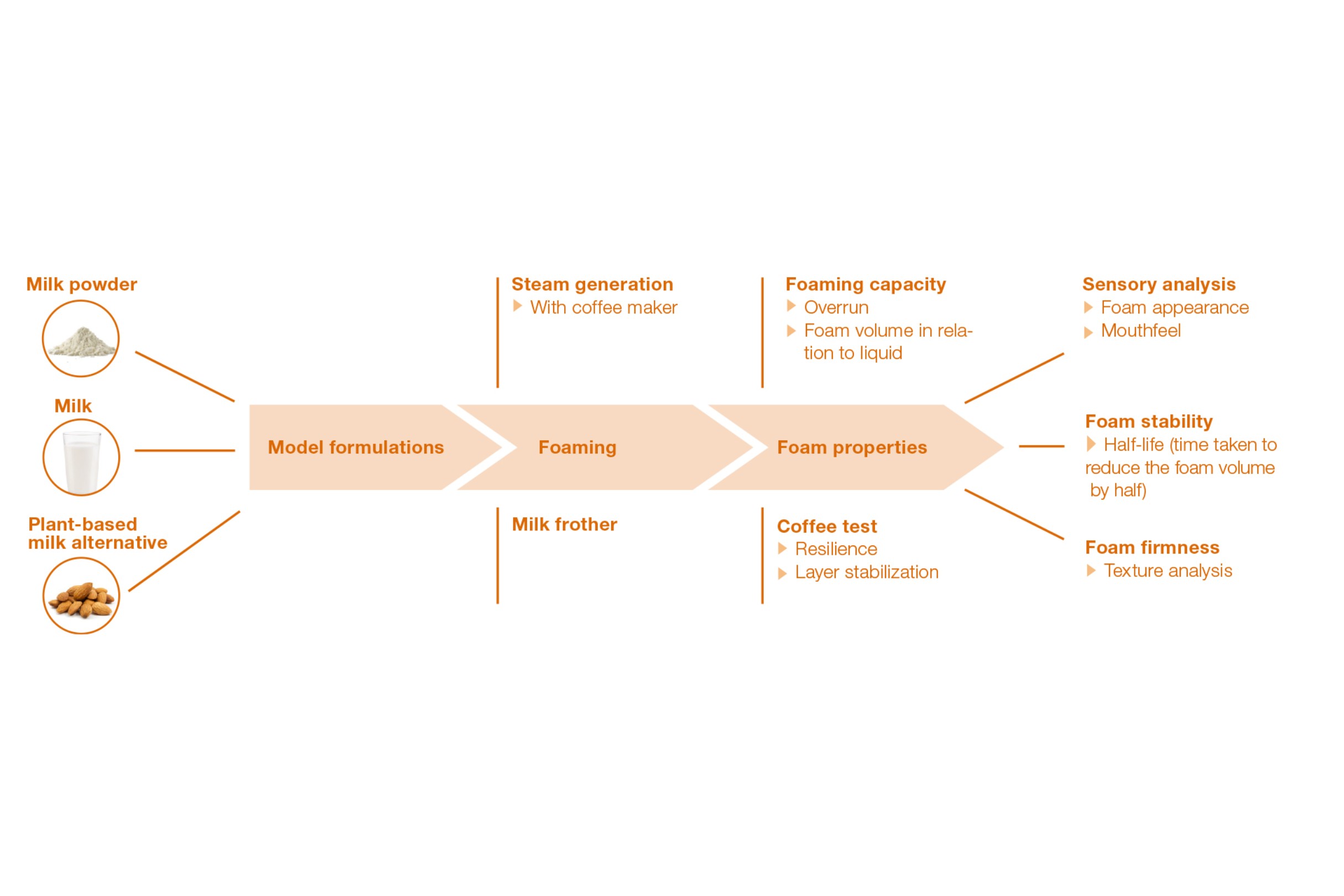

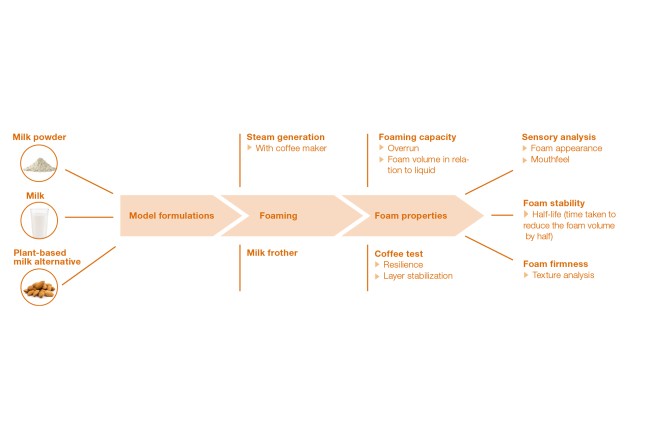

With alpha-cyclodextrin – a cyclic sugar molecule based on plant starch – WACKER BIOSOLUTIONS offers an ingredient that promotes exactly these properties. “We used various model formulations to examine the influence of alpha-cyclodextrin on foam properties such as volume, stability and texture,” she reports. The model formulations that the expert is referring to used different plant-based milk alternatives and milk powder alongside cow’s milk as starting materials for the foam.

Milk Foam for the Senses

Tested Model Formulations, Foaming Processes and Foam Properties

Milk powder: dairy and non-dairy milk toppings in powder form with varying fat content; milk:

ultra-high temperature (UHT) milk with varying fat content; plant-based milk substitute: (in this case almond milk with 2.5% almond content). The foam was created either by injection of steam with a coffee maker or by using a milk frother. Different properties of the resulting foam were subsequently analyzed.

All of these milk alternatives are gaining in popularity: market studies confirm that the demand for soy and almond milk is rising by around 10 percent per year in the US alone. Additionally, powder-form, milk-based specialty products are used to make alternative toppings to fresh milk that are particularly long-life and easy-to formulate into compound systems.

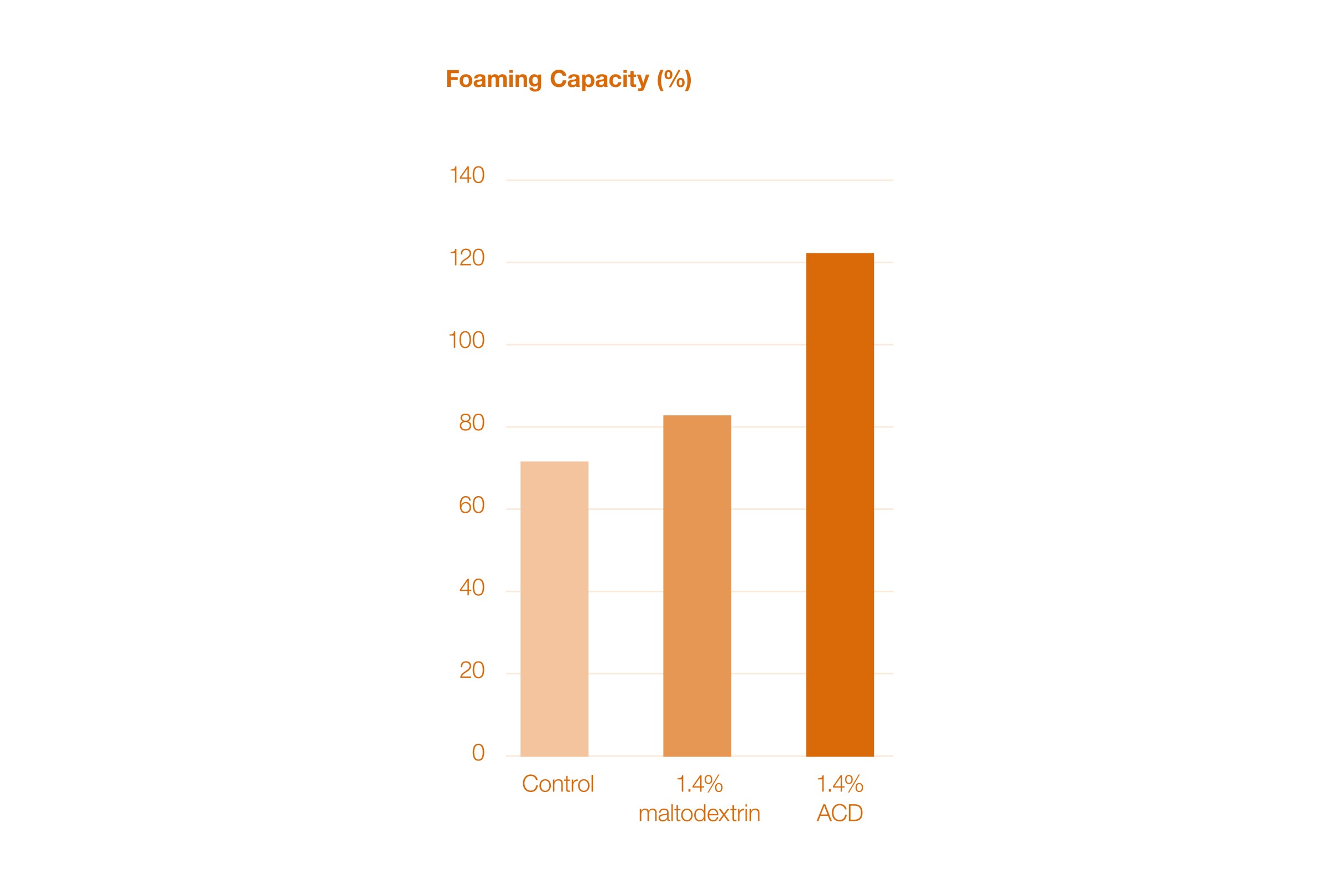

Reversibly Encapsulated

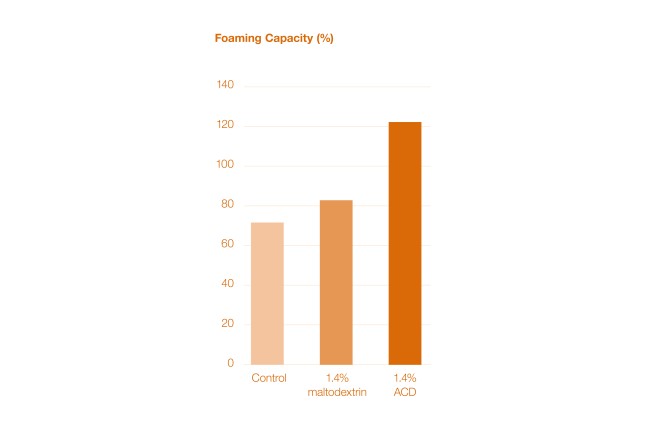

Tests at WACKER’s food laboratory in Burghausen are producing impressive figures that confirm the positive effect of cyclodextrins. WACKER markets these cyclic sugar molecules, which are able to reversibly encapsulate other molecules (see box below), under its CAVAMAX® brand. The addition of 1.4% CAVAMAX® W6 to a milk-powder product of medium fat content almost doubles the volume of the resultant milk foam, for instance. CAVAMAX® W6 is produced from plant starch in a patented process. It consists of six glucose (dextrose) units, linked together in a ring. WACKER BIOSOLUTIONS uses starch to manufacture the product in an enzymatic process.

Cyclodextrins

Cyclodextrins are oligosaccharides that WACKER BIOSOLUTIONS manufactures from plant starch. The raw-material base is corn. Cyclodextrins are characterized by their cyclic three-dimensional structure with a hydrophobic cavity. This cavity can trap lipophilic molecules as “guests” – provided they have the right size and shape. The hydrophilic outer surface in turn ensures compatibility with aqueous systems. This special structure exhibited by cyclodextrins opens up a wide range of applications in pharma, food, food supplements and technical applications. Cyclodextrins can be used for stabilizing sensitive substances, for controlled release of bioactives, masking unwanted aromas, rheology control or for improving solubility and bioavailability.

Depending on the size of the ring, a distinction is made between α-cyclodextrin with six, β-cyclodextrin with seven and γ-cyclodextrin with eight glucose units. WACKER is the only company in the world to manufacture all three naturally occurring cyclodextrins. They are marketed under the following trade names: CAVAMAX® W6 (α-cyclodextrin), W7 (β-cyclodextrin) and W8 (γ-cyclodextrin).

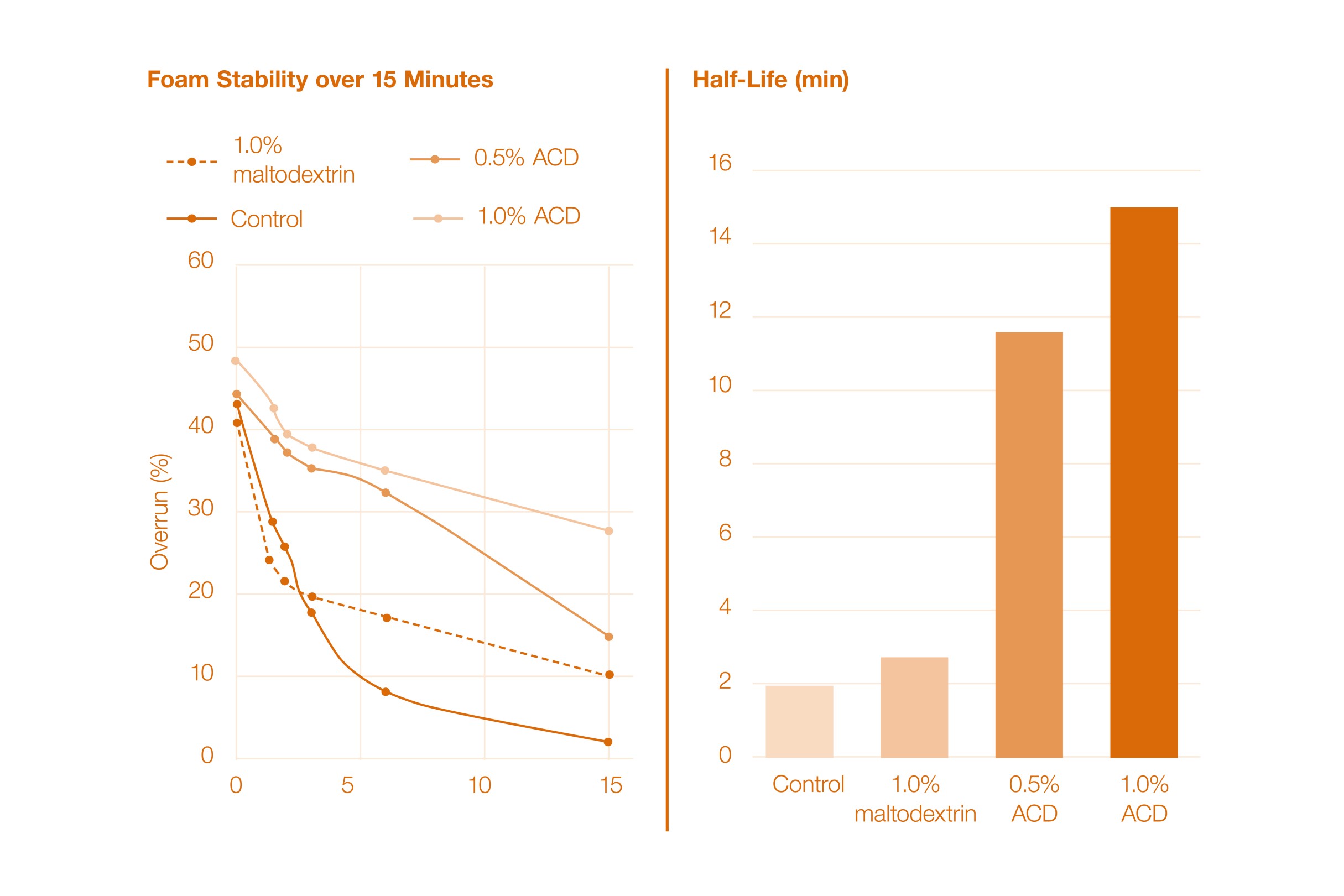

Foam Remains Stable for Longer

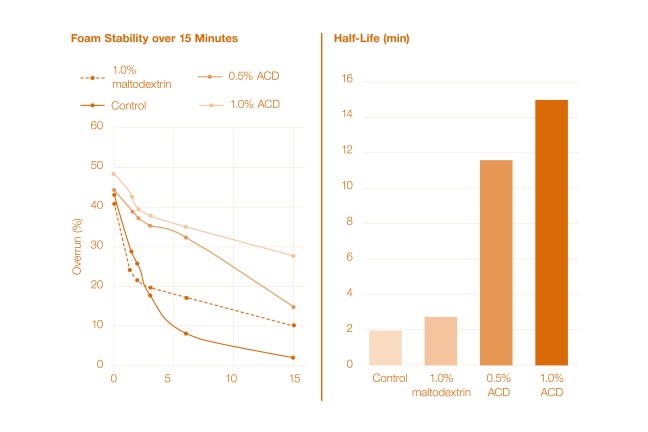

On top of the positive influence on foam volume and stability, alpha-cyclodextrin has other desirable effects: the half-life, as experts refer to the time taken for the foam volume to reduce by half, can be increased considerably with the addition of CAVAMAX® W6 – from 3 to 15 minutes. “This provides consumers with a longer period during which the coffee-based beverage can be served with an attractive topping,” explains Dr. Fischer-Nägele. “The coffee looks good in the cup for considerably longer.”

Her colleague Yvonne Haslauer describes a further benefit of the vegan additive: “A foam created with the addition of CAVAMAX® W6 looks more uniform and creamier than the corresponding pure milk foam – an effect that immediately catches the consumer’s eye.”

WACKER BIOSOLUTIONS food specialists have an explanation for the foam-enhancing effect: alpha-cyclodextrin has a hydrophilic (water-attracting) exterior and a lipophilic, i.e. fat-loving, cavity. “This lipophilic cavity can form an inclusion complex with milk constituents such as triglycerides. They thus control the convergence of the liquid phase, stabilizing the foam structure,” says Haslauer. Here, the liquid phase is the milk, which is converted into a dispersion (gas/liquid = foam) by the foaming process. “These stabilized barista toppings can be savored both on coffee-based drinks and tea drinks such as chai latte as a tasty lifestyle add-on,” she explains.

Foam volume of different barista formulations:

The addition of 1.4% alpha-cyclodextrin (ACD) almost doubles foaming. The same amount of an inert, linear oligosaccharide (maltodextrin) was used as a control for the foam volume. Maltodextrin only slightly increased the overrun, due to the increase in dry matter. Addition of alpha-cyclodextrin to the barista topping not only improves the foaming capacity – CAVAMAX® W6 also retards foam-reducing processes (Ostwald ripening, dehydration, coalescence and drainage) and thus has a positive influence on foam stability in these toppings.

Foam volume of different barista formulations

Foam stability with alpha-cyclodextrin:

The diagram depicts the increase in foam stability for dairy and non-dairy milk powder toppings, reconstituted from four grams of powder in 100 grams of water. The addition of alpha-cyclodextrin increases foam stability even at low dosages and extends the foam half-life (time taken for the foam volume to shrink by half) from 3 to 15 minutes. Barista products are part of a luxury lifestyle. This means that consumers attach great importance not only to the topping’s volume and stability, but also to its overall appearance. The foam should look nicely creamy and uniform. Consumers correlate this uniform, creamy pore structure with a full-bodied drink and enhanced mouthfeel. Plant-based barista toppings, in particular, often require a bit of help in this regard.

Foam stability with alpha-cyclodextrin

Professional Tasters

Aside from the improved foam stability, alpha-cyclodextrin can also have a positive impact on the taste of plant-based milk alternatives. This sensory aspect can be analyzed by means of a triangle test. This test involved 18 women and men standing in a line along a table in a room with neutral lighting; their places are separated from each other by a small, non-transparent panel. They each receive three glasses containing a milky liquid. The professional tasters must find out which of their three glasses differs from the others.

The glasses contain either pure almond milk or almond milk with 1% alpha-cyclodextrin. In this triangle test, a method described in an ISO standard, 12 out of the 18 tasters from an independent institute succeeded in correctly identifying the divergent sample in each case. The tasters described the pure almond milk as watery, nutty, bitter and lacking in body. The term “astringent” was also used, describing a puckering feeling in the mouth. By comparison, they found the almond milk with CAVAMAX® W6 on average to be more full-bodied and creamy and less bitter.

Mrs. Dr. Ulrike Fischer-Nägele

Head of Technical Service for Nutrition

WACKER BIOSOLUTIONS

+49 8677 83-87356

ulrike.fischer-naegele@wacker.com