WACKER Presents Fire-Resistant Silicones for the Electrical and Railway Industries at CWIEME

Munich, May 10, 2022

The Munich-based chemical company WACKER will be presenting silicone products for the electrical and railway industries at this year’s international electrical engineering trade show CWIEME. The focus is on the new silicone resin SILRES® H60 and on the silicone rubber grades ELASTOSIL® N 2076 and ELASTOSIL® RT 607. All three products insulate and protect key components in electrical drives. SILRES® H60 is used to impregnate motor windings, while ELASTOSIL® N 2076 protects electrical coils from harmful environmental influences. ELASTOSIL® RT 607 prevents moisture and dirt from entering the stator’s lamination stack. The latter two products comply with the European Union’s fire protection standard in rail vehicles. CWIEME will take place from May 10-12 in Berlin, Germany.

The material testing standard EN 45545-2 has been in force since 2016 for European manufacturers of materials and components for rail vehicles. It regulates the fire protection requirements of all installed components in the EU, including the insulating materials used in the production of electric drives. WACKER offers a wide range of product solutions based on solid and liquid silicone rubber as well as on room-temperature-vulcanizing (RTV) silicones for most of the applications and hazard levels listed in the standard.

At the electrical engineering trade show CWIEME, the company will be presenting two types of silicone rubber, which meet the current standard for fire protection in rail vehicles. These are the room-temperature-crosslinking silicones ELASTOSIL® N 2076 and ELASTOSIL® RT 607.

ELASTOSIL® N 2076 comes under the spotlight for the first time. Under sufficient humidity, the one-component coating grade cross¬links to a medium-hardness flexible silicone rubber. It thus permanently protects electrical windings, for example of transformers or choke coils, from moisture, dirt and deposits. ELASTOSIL® N 2076 is weather and UV resistant, electrically insulating and heat resistant. The elastomer is even suitable as a protective coating for the winding head of traction motors that reach temperatures up to 200 degrees Celsius in continuous operation.

Its flame-retardant properties are outstanding. In contrast to the predecessor product ELASTOSIL® N 288, ELASTOSIL® N 2076 meets the corresponding requirements of the European standard EN 45545-2 for fire protection in rail vehicles. The product is approved for internal components that fall under requirement set R 22 and have been classified for hazard levels HL 1 and HL 2. For external components, ELASTOSIL® N 2076 is also suitable for the highest hazard level HL 3 in accordance with the requirement sets R 23 and R 24.

ELASTOSIL® RT 607, too, is suitable for fire protection-related appli-cations in the field of electrical engineering. The two-component addition-crosslinking silicone rubber has been used for years as a potting compound in traction motors. It is flame retardant and meets the requirements for internal and external components in accordance with the requirement sets R 22, R 23 and R 24 defined in EN 45545 2. The room-temperature vulcanizing rubber crosslinks rapidly and has a hardness of 55 Shore A, when cured. ELASTOSIL® RT 607 is extremely heat-resistant and can withstand operating temperatures of up to 230 degrees Celsius.

Rapid Curing Silicone Resin SILRES® H60

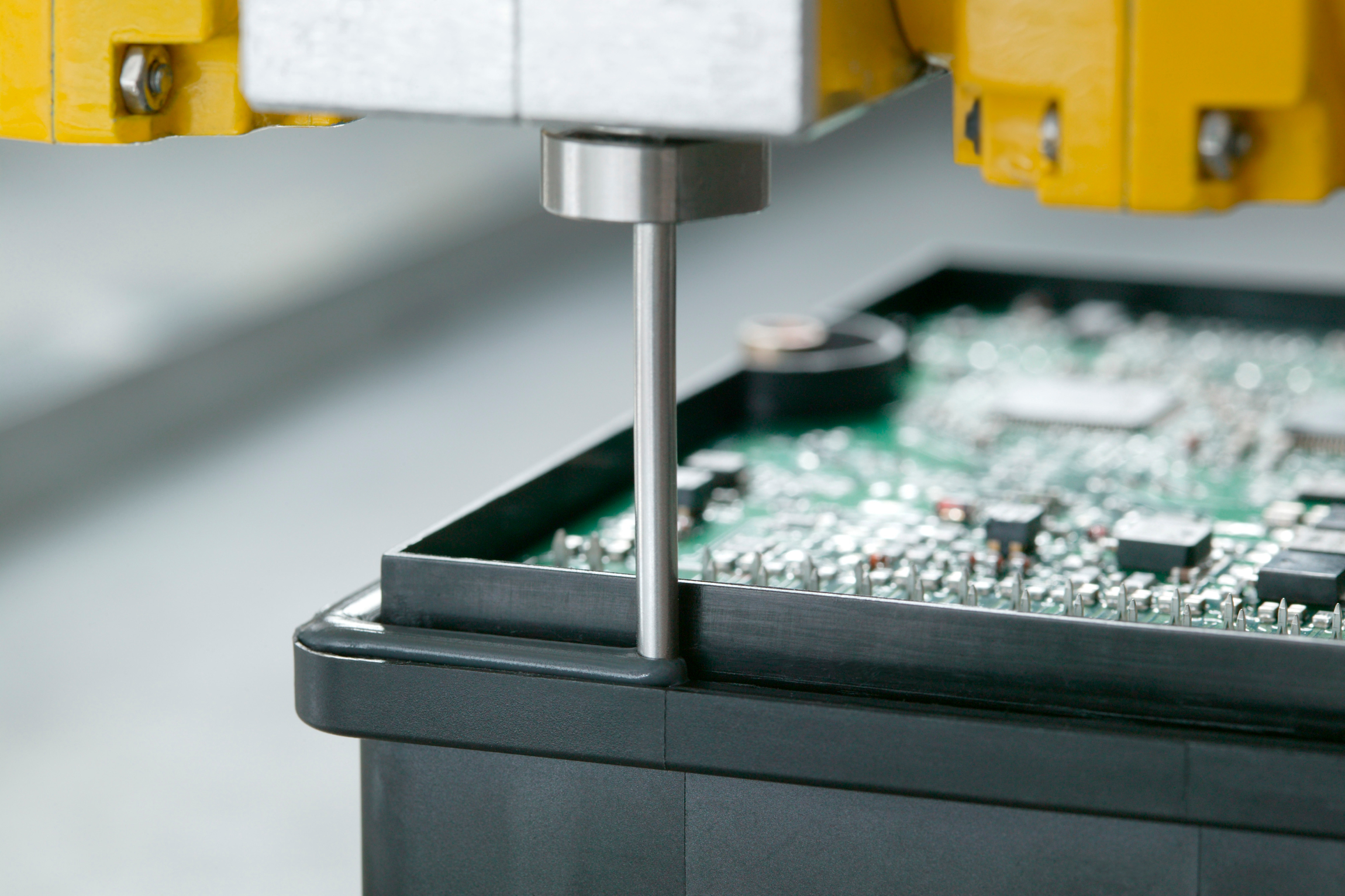

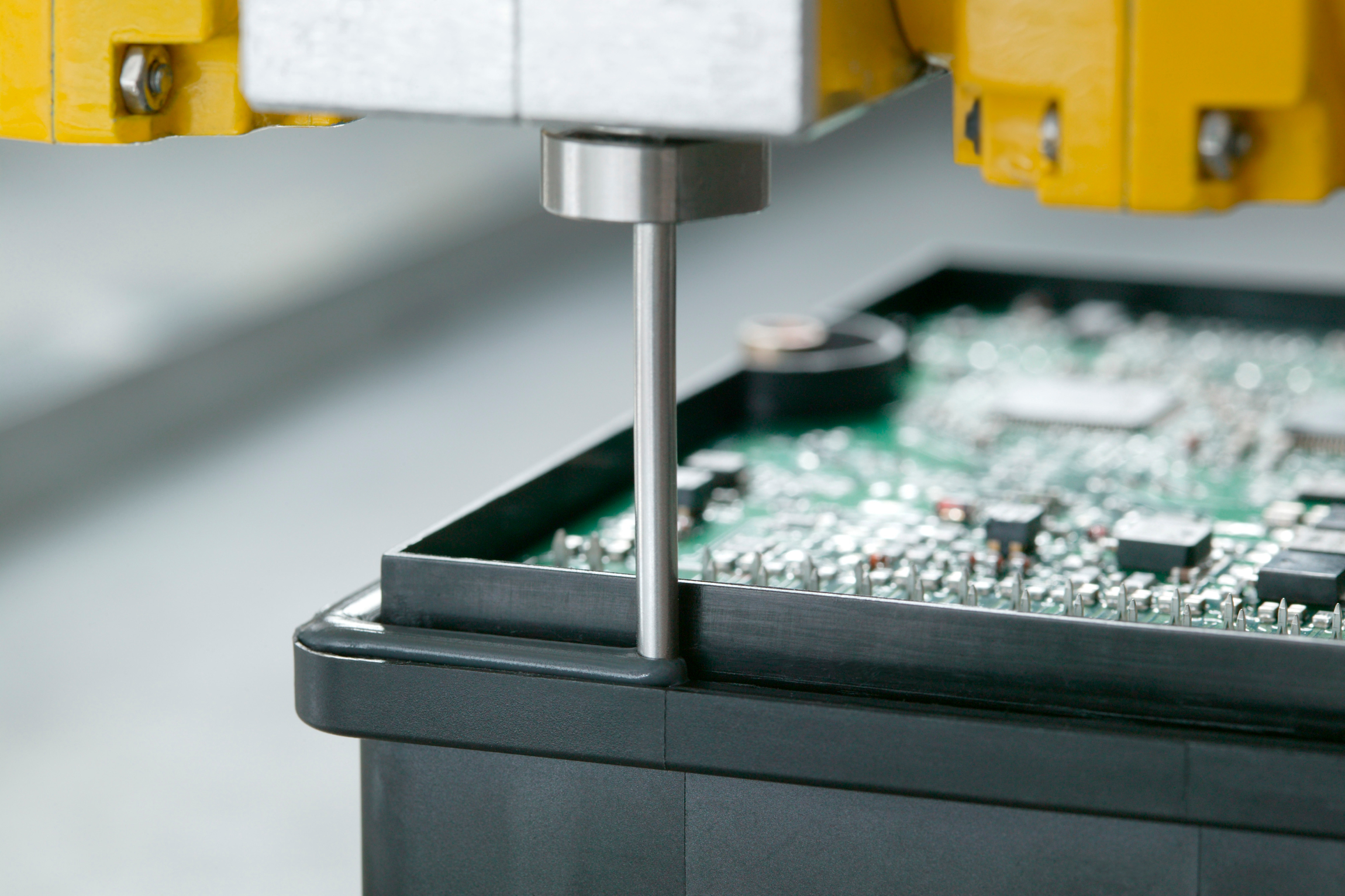

SILRES® H60 is a two-component phenyl silicone resin for the impregnation of copper wire windings in electrical drives. The product is free of solvents and reactive diluents and crosslinks in a platinum-catalyzed addition reaction to a thermoset of the hardness Shore D 65. The cured resin insulates well and withstands long-term heat loads.

The product is particularly suitable for impregnating copper-wire windings in the stators of thermally highly loaded electric motors. During impregnation, a thin layer of resin forms on the copper wires, which fills the cavities of the winding and displaces the air between the individual wire layers. This strengthens the winding and protects it from moisture and dirt. The impregnation also improves electrical insulation and improves heat dissipation.

SILRES® H60 is particularly suitable for application by trickle impreg-nation. This technique involves trickling the insulating resin onto the end windings of the stator coil until the resin is spread evenly over the coil winding. This allows manufacturers of electric motors to impregnate large numbers of windings very quickly, which is not possible when conventional dip impregnation or vacuum-pressure impregnation is used. SILRES® H60 can therefore be seen as a productivity-enhancing supplement to SILRES® H62 C, which has a proven track record of many years in winding impregnation. With regard to thermal resistance, SILRES® H60 complies with the thermal class R, according to EN 60085. This means that it can withstand temperatures up to 220 degrees Celsius permanently.

Further product highlights at CWIEME 2022:

ELASTOSIL® N 9111

The tin-free formulated one-component silicone rubber is a versatile adhesive and sealant for applications in the automotive, electrical, and electronics industries. It cures at room temperature in the presence of atmospheric moisture and is characterized by excellent heat resistance and good mechanical properties. The silicone adheres to many substrates such as aluminum, stainless steel, glass, polyamide or polyvinyl butyral and offers continuous thermal stability up to 200 degrees Celsius when cured. ELASTOSIL® N 9111 complies with the UL94 V-0 fire safety standard of the US testing institute Underwriters Laboratories.

SILRES® 64558 VP

The product is a ready-to-use formulation of polysiloxanes and silicone resins and is used as a binder in highly flexible mica tapes for traction motors. SILRES® 64558 VP improves both the insulating properties and the heat resistance of such tapes. In addition, it reduces moisture absorption and thus extends the lifetime of the primary insulation in thermally highly loaded traction motors.

SILRES® MK and SILRES® H44

SILRES® MK and SILRES® H44, both condensation-curing silicone resins, are used either as water-repellent binders or as impregnation material for porous materials. They are resistant to UV, heat and weathering and improve the electrical resistance of composite materials. SILRES® MK is available as powder or flakes, SILRES® H44 is only available as powder. When cured, both silicone

resins withstand temperatures up to 300 degrees Celsius without restrictions.

Visit WACKER at CWIEME in Hall 3.2, Booth B34.

Presspicture

SILRES_Flakes_Fluid_Powder

ELASTOSIL_N9111

SILRES_H60_Coatings

Contact

Wacker Chemie AG

Media Relations

Florian Degenhart

Tel. +49 89 6279-1601

Email florian.degenhart@wacker.com

Send Message

Download

Press Information

(PDF | 349 KB)