- Home

- Products & Services

- Product Groups

- Silanes, Siloxanes & Silicates

Silanes, Siloxanes & Silicates

Silanes act as molecular bridges between organic and inorganic materials and are used as adhesion promoters in a wide range of applications.

Silanes are the starting materials and the main ingredients in silicone production. WACKER was a pioneer in the manufacture of silicones and started producing silanes in 1950. WACKER manufactures silanes in its integrated production system by direct synthesis from silicon and methyl chloride (Müller-Rochow synthesis). Silicates are produced from tetrafunctional silanes.

Silanes

Special silanes are used as synthetic building blocks in the chemical and pharmaceutical industries. WACKER offers a wide portfolio of organofunctional and non-functional silanes.

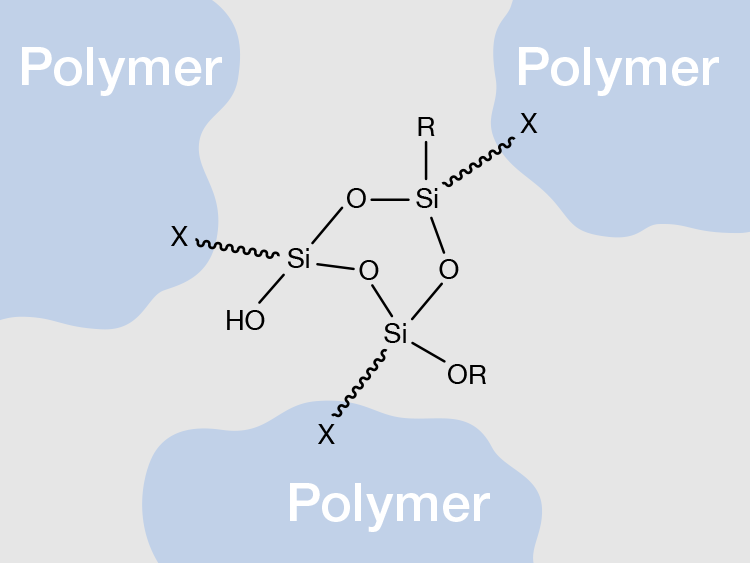

Organofunctional silanes are hybrid compounds that combine the functionality of a reactive organic group with the inorganic functionality of an alkyl silicate in a single molecule. As a result, organofunctional silanes can be used as molecular bridges between organic and inorganic materials. This bridging property is highly important in many applications and industries. Silanes are colorless, clear, volatile liquids that are soluble in organic solvents - including alcohol in some cases.

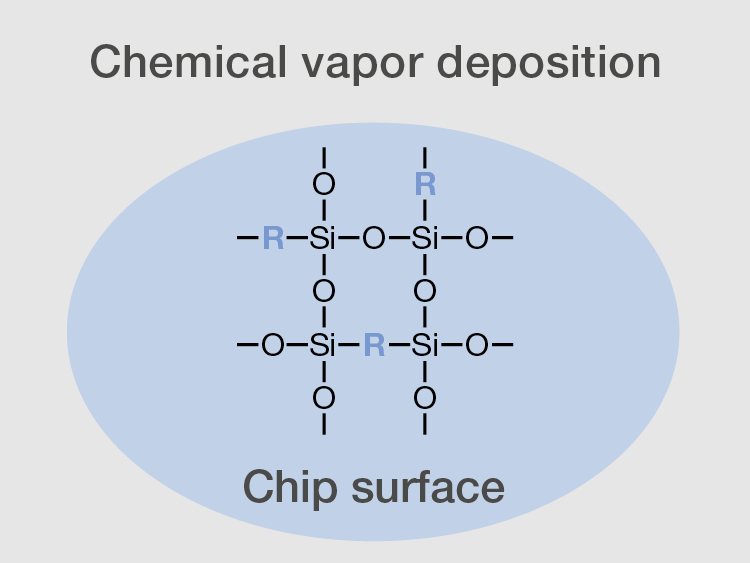

In the semiconductor industry, silanes play a crucial role as precursors for chemical vapor deposition (CVD) and atomic layer deposition (ALD). These processes, which are used for creating ultra-thin, high-quality films for silicon-based insulating layers and interconnects, are essential for chip manufacturing and for enhancing device performance and scaling. Their reactivity and versatility make them a key component in fabricating next-generation electronics.

WACKER Brands:

- GENIOSIL®

- SEMICOSIL®

- SILRES®

Applications

- Adhesion promoter and coupling agent for better anchorage of coatings, adhesives and sealants to many different substrates

- Surface modifiers for optimizing compatibility and permitting the chemical bonding of inorganic fillers to organic polymers

- Curing agents for organic polymers, for example in moisture-curing adhesives and sealants, paints and coatings

- Water scavengers in moisture-curing polymers

- Co-catalysts in polypropylene production

- Crosslinkers for polyethylene in the production of heat-resistant pipes or insulating cable sheathing

- Water-repellent agents for protecting construction materials

- Silylating agent

- Dielectrics in semiconductor components

Industries

- Coatings

- Adhesives

- Sealants

- Plastics industry

- Colors

- Construction materials

- Pharmaceutical industry

- Semiconductor industry

Silane creams, emulsions, powders and mixtures

WACKER’s portfolio includes various silane-based formulations for applications-specific solutions. A mixture of silanes and siloxanes can be used to achieve the desired balance between penetration behavior and surface effects.

WACKER Brands

- SILRES®

Applications

- Hydrophobic agents for protecting masonry and construction materails

- Protecting the infrastructure against the ingress of harmful salts

- Protecting concrete against destructive chemical processes

- Admix applications in dry-mix mortars and concrete

- Damp-proofing against rising damp

Industries

- Construction

- Construction chemicals

- Construction materials

Silane Creams

Silanes with a creamy consistency can be easily applied to vertical surfaces in large amounts and feature a relatively long contact time between the silane and surface. This intensifies the penetration and therefore improves the overall performance.

Silane Emulsions

Silane-based emulsions can be diluted with water or easily incorporated into water-based formulations without high-shear mixing.

Silane Powders

Silane-based powders are ideal for adjusting the hydrophobic properties of dry-mix compositions to meet requirements.

Silane Mixtures

Silane-siloxane-based concentrates can be diluted with organic solvents for use as highly effective water-repellent agents. Treated substrates are permanently protected.

Silane-siloxane-based silicone microemulsion concentrates, form dilute microemulsions in water. They feature excellent penetration behavior and have many potential applications.

Ethyl Silicates

Silicates are derived from oligosilicic acids and differ from silicones in their residual alcohol-group content. Further curing takes place by the addition of catalysts, such as sulfuric acid.

Silicates include all salts and esters of silicic acid. Organic silicates, such as esters of mono- and di-silicic acid can only be produced synthetically. With the exception of alkali silicates (water glass), the inorganic silicates form an important group of naturally occurring silicon-oxygen compounds (silicate materials).

WACKER Brands

- SILRES®

Applications

- Stone conservation

- Binders for zinc-rich coatings

Industries

- Construction

- Coatings

Methyl Siliconates

Potassium methyl siliconate is a highly alkaline aqueous solution. Diluted with water, it is used for in-plant water-repellent impregnation of heavy clay products such as roofing tiles, floor tiles and flowerpots. After the water has evaporated, the potassium methyl siliconate reacts with atmospheric carbon dioxide (CO2). This produces potassium carbonate (K 2 CO 3 ) and the water-repellent agent poly(methyl silicic acid).

WACKER Brands

- SILRES®

Applications

- Hydrophobic agents for clay-based materials such as bricks and roofing tiles.

- Surface treatment of gypsum fiberboards

- Impregnation of insulating materials (perlite, expanded clay, etc.)

- pH adjustment in water-based coatings

- pH control in the production of polymer dispersions

Industries

- Construction materials

- Coatings

Silazanes

1,1,1,3,3,3-Hexamethyldisilazane is a colorless liquid with a purity of at least 97.0 percent, at least 98.0 percent or at least 99.0 percent It can be used as a universal silylating agent, for example, for the derivatization of alcohols, carboxylic acids, amines and amides.

Applications

- Universal silylating agent, for example for derivatization of alcohols, carboxylic acids, amines or amides

Industries

- Pharmaceutical

Brochures

SILICONES – Definition and Properties

Want to know more about WACKER silicones?