Benefits of a Vacuum

Vacuum bags made of silicone increase the efficiency of making parts from fiber-reinforced plastics, especially in small-series production. The French company Durisotti uses the process to make floor panels for handicapped-accessible buses.

Of all materials, a great deal of hope is being pinned on fiber-reinforced plastics, which offer a compelling mix of stability, low weight and huge design latitude. They therefore have the ideal properties for automotive and aircraft makers. Their special properties are more than just the sum of their two parts, however. Fiber-reinforced plastics are much more stable than the combination of the stability conferred by pure fiber and plastic encasement would lead one to expect. In the direction of the fiber, they are especially rugged because the fibers are firmly embedded in the structure by the surrounding plastic matrix. This high stability is the reason that fiber-reinforced plastics find application in Formula 1 racing, the aviation industry and the rotors of wind turbines. Not only that, but they are relatively easy to process, which is why small runs needed for these applications can be made economically.

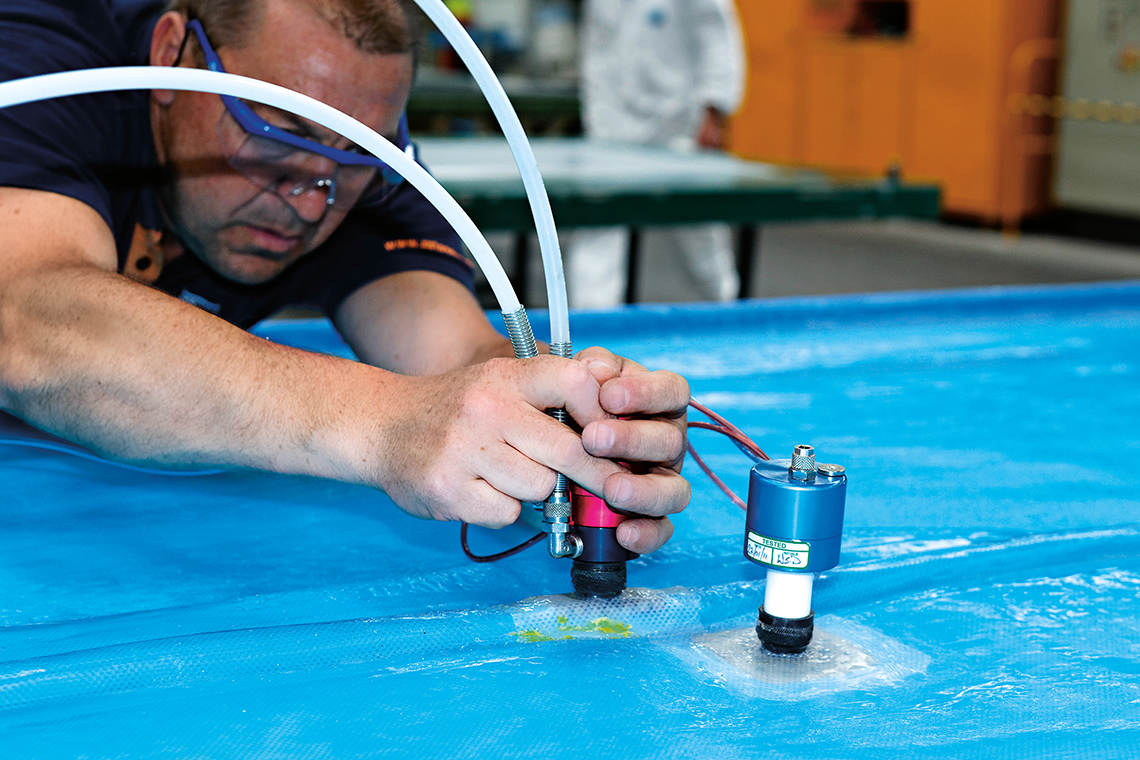

Durisotti employees need just five minutes to exactly position the silicone vacuum bag on the workpiece. The former production process required over an hour for positioning and sealing of the plastic sheeting.

It is precisely all these qualities that appeal to Durisotti, a French company. This family-run business specializes in converting mass-produced vehicles to meet special purposes. It adapts vehicles to suit the needs of emergency services, transport and bus companies, craftsmen and commercial companies. The company, based in Sallaumines on the Belgian border, has by now adapted more than 27,000 vehicles. Customers include the French postal service and police, Air France and the city authorities in Paris.

The use of heavy materials should be avoided in retrofitting work, as they would reduce the available payload and increase fuel consumption. Nonetheless, there may be no compromises on stability either – which could jeopardize the vehicles’ roadworthiness And with special superstructures and modifications, it is often the case that unusual, complex parts are required that meet the customers’ specific needs. Large production runs of these special-purpose vehicles are generally unlikely.

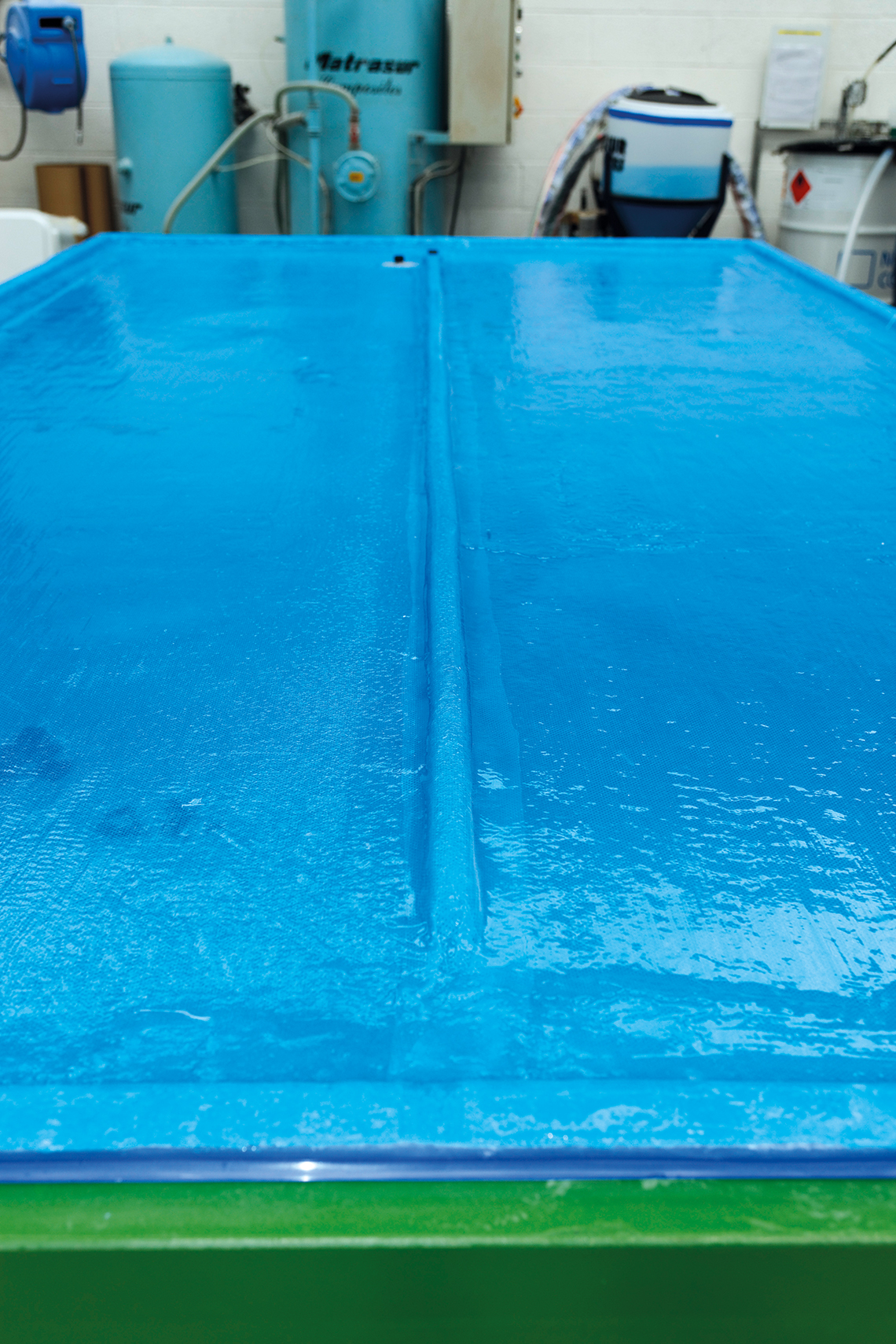

Durisotti has been working with composites since the 1970s, and some of its structures have been as voluminous as 20 cubic meters. For a long time, its typical working process for making the composite workpieces consisted of charging the fiber component, resin and hardener into a half-mold, which was then covered with plastic sheeting that had to be laboriously taped all around the edges. A vacuum pump then extracted the remaining air from the mold and at thesame time ensured that the still-liquid resin was evenly distributed. When the resin hardened, the plastic sheeting was removed and disposed of. They then removed the finished workpiece from the mold. The disadvantage of this process was that it generated a great deal of waste and sealing the molds before the vacuum was applied was a tedious, labor-intensive task.

Composite Workpieces Using ELASTOSIL® C Silicone Rubber Bags

More Efficient Process

The metal tracks serve to sufficiently anchor the interior's seats.

Durisotti has now adopted a technique developed by Magnum Venus Products (MVP), an American company, in cooperation with WACKER. Instead of plastic sheeting, which can only be used once before disposal, a vacuum bag made of silicone rubber is used. This can be reused and, because there is a gasket all around its rim, it does not need to be laboriously sealed. It only needs to be placed on top and correctly positioned. When the vacuum pump is switched on, the bag is placed under vacuum and automatically seals the rim.

The vacuum bags are made with the aid of a silicone system solution called ELASTOSIL® C which was developed by Wacker Chemie specifically for standard processing and production methods. With this product line, a re-usable, perfectly fitting, fabric-reinforced silicone vacuum bag can be made by the spray or brushing technique. ELASTOSIL® C 1200 is structurally viscous and, with a workability time of 20 minutes, is also suitable for larger, custom-sized workpieces, e.g. as neededfor shipbuilding or wind turbines. The bags are reinforced with FABRIC C from WACKER, which is part of the systemsolution and which imparts tensile stability.

Durisotti currently uses vacuum bags made of ELASTOSIL® C 1200 to make floor panels intended for wheelchair-friendly retrofitting of Renault Master vans. Whereas it usually took two employees a good hour to apply and seal the plastic sheeting on the workpiece in the old production method, now it only takes aroundfive minutes to properly position the silicone vacuum bags. As a result, Durisotti has not only boosted productivity: “Our employees are delighted that the mold can be closed faster, as the solvent in the resin has less time to escape,” explains composite department manager Jean-Michel Kosowksi. “That makes working with the resin a lot more pleasant for them.”

The company believes that there is even more scope for boosting the efficiency of the method "We're in regular contact with our partners at Magnum Venus Products and Gazechim, our WACKER distributor, to make the most of our possibilities," explains Kosowski.

Clear Benefit from Silicone Vacuum Bags

The benefits gained through the production of the floor panels are offset by the additional outlay for making the vacuum bags. "But the payback period is very short, because the hoods are made in just two-and a-half hours and can be used more than 250 times," says Andreas Sick from Product Marketing within the Industrial Solutions business team at WACKER SILICONES.

The process can essentially be applied to almost all fiber-reinforced plastics. However, workpieces made from carbon fibers, which car maker BMW wants to make large body parts from in the future, can be produced by the method. The MVP method is thus right on trend – market researchers are convinced that the future belongs to composites Experts believe that production volume for carbon fibers alone will virtually double within the next four years.