INDEX 2021: WACKER Showcases Its Product Line Based on the Biomass Balance Approach under New Name of VINNAPAS® eco

Munich, Oct 06, 2021

WACKER, the Munich-based chemical group, will be presenting a wide range of polymeric binders for nonwovens and textiles at INDEX 2021. The company’s focus will be on sustainable solutions based on the biomass balance approach. WACKER will also be unveiling a new name for the portfolio in question: products that until now have been marketed under the VINNECO® brand name will be called VINNAPAS® eco going forward. From this point onward, the suffix “eco” will apply to all WACKER products that conserve fossil raw materials and instead use raw materials certified as sustainable according to the biomass balance approach. A leading tradeshow for nonwovens, fibers and bonded fabrics, INDEX will take place October 19 – 22, in Geneva, Switzerland.

Aqueous dispersions are indispensable starting materials for manufacturing nonwoven fabrics and technical textiles. When added to table napkins, wet wipes and feminine hygiene products, for example, dispersions improve the properties of these nonwovens, such as softness, mechanical stability and absorbency. Here WACKER offers a comprehensive portfolio of technologically mature dispersions suitable for a wide array of applications in both its classic VINNOL® and VINNAPAS® product lines, as well as its exceptionally sustainable VINNECO® products.

WACKER will also be debuting a new name for its VINNECO® line at INDEX 2021: products from the VINNAPAS® family will now be sold as an explicitly sustainable brand called VINNAPAS® eco. While this means that VINNAPAS® eco will now replace the VINNECO® brand name, the property set of these products will not change in any way as a result. Renaming the grades in question will be complete by December 1, 2021. It will affect products for textiles and nonwovens, along with products for other applications, such as dispersions and dispersible polymer powders for the construction industry, and dispersions for paints and adhesives.

WACKER accepts its responsibility for climate change and aims to achieve carbon neutrality. Raw materials are a major factor in accomplishing that goal. In order to increase its use of renewable raw materials, the group applies the biomass balance approach – an approach used for verifying that a given product conserves fossil raw materials throughout the supply chain by incorporating certified sustainable biomass. In the future, the word “eco” will be added to the names of all such products.

Production Based on the Biomass Balance Approach

WACKER uses bio-based acetic acid to manufacture its VINNAPAS® eco polymeric binders. This substance is formed as a byproduct of wood-industry processes such as preparing fibrous material for paper manufacturing. The bio-based acetic acid used at WACKER has been certified by the PEFC® (Programme for the Endorsement of Forest Certification) and stems from sustainably managed forests located within a radius of 400 km of WACKER’s Burghausen site. WACKER uses bio-based acetic acid and ethylene to produce vinyl acetate monomer, which – again using ethylene – is copolymerized to form vinyl acetate-ethylene (VAE). In production, bio-based acetic acid can be blended with conventional acetic acid, and is thus directly coupled into WACKER’s existing production line. The compound always exhibits the same chemical and physical behavior, regardless of whether it was derived from fossil-based or renewable raw materials, ensuring uniformly high quality.

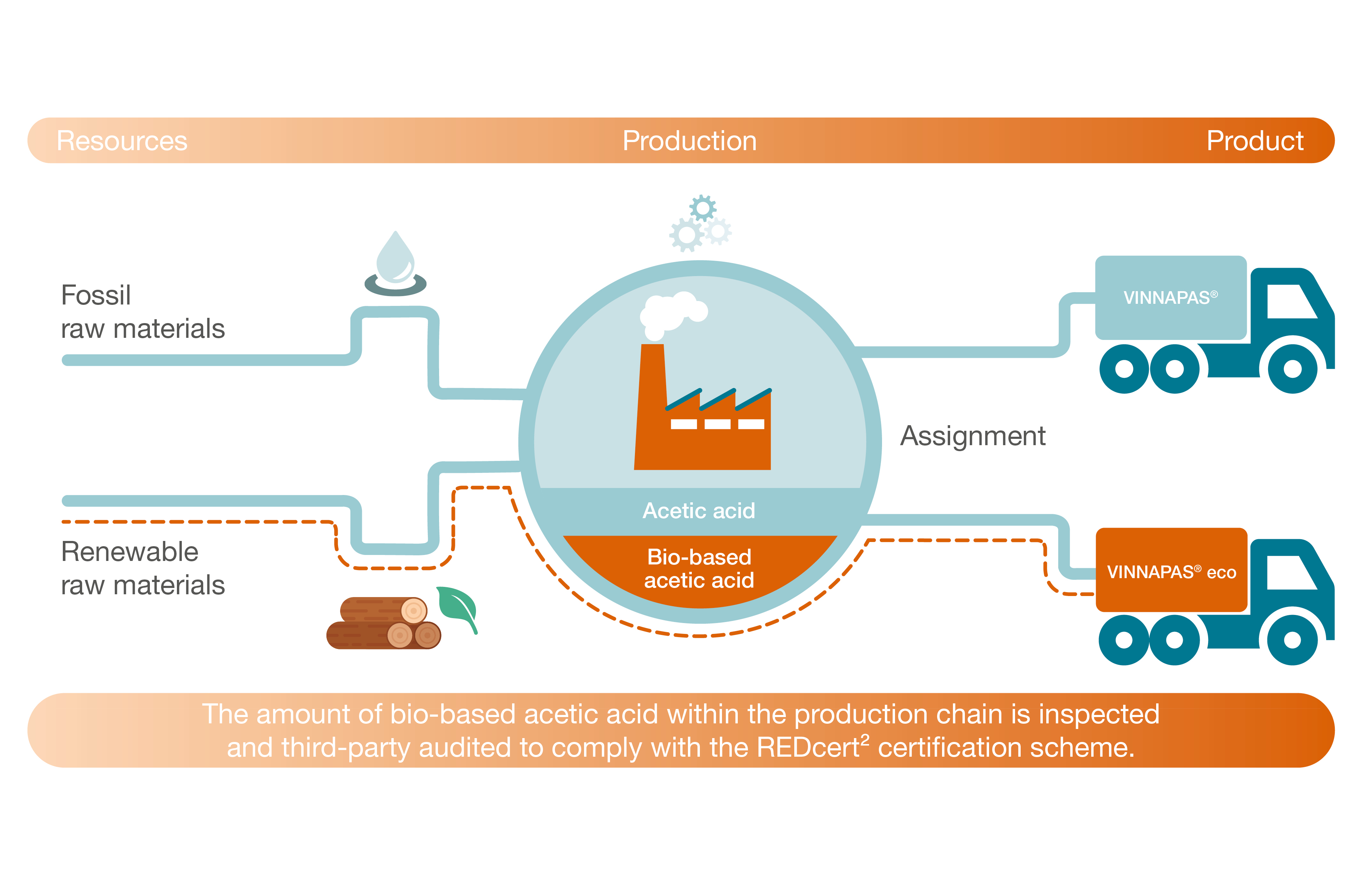

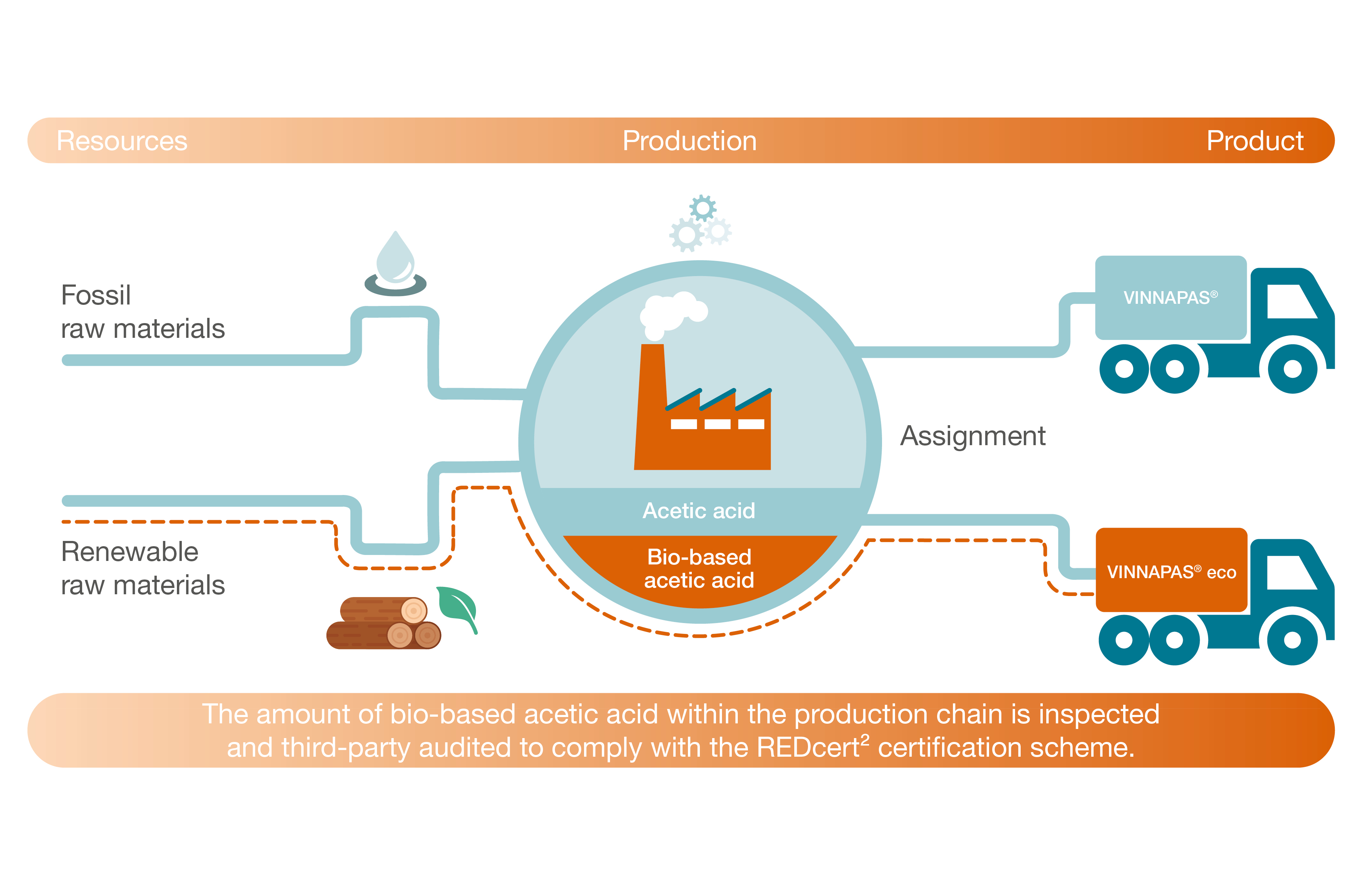

The biomass balance approach involves mathematically assigning the raw materials used to the sales of individual products. The bio-based acetic acid used, for instance, is allocated in this way to fossil resources saving products, with the balance of the sales being allocated to other products based on the use of fossil derived raw materials, mathematically speaking. No new production facilities are required. Products comply with the REDcert² certification scheme and are audited by TÜV Nord as an external third party. When customers buy one of the resulting products, they receive a REDcert² certificate guaranteeing that the product saves fossil resources by using sustainably certified renewable raw materials in the value chain.

About WACKER POLYMERS

WACKER can look back at over 80 years’ experience in the manufacture of polymer binders. Today, WACKER POLYMERS is a leading producer of state-of-the-art binders and polymeric additives based on polyvinyl acetate and vinyl acetate copolymers. These take the form of dispersible polymer powders, dispersions, solid resins, and solutions. The products are used in construction chemicals, paints, surface coatings, adhesives and nonwovens, as well as in fiber composites and polymeric materials based on renewable resources. WACKER operates production sites for polymer binders in Germany, China, South Korea and the USA, as well as a global sales network and technical centers in all major regions.

Visit WACKER at INDEX 2021, Booth 1233.

Contact

Wacker Chemie AG

Media Relations

Manuela Dollinger

Tel. +49 89 6279-1629

Send message

Download

Press Information

(PDF | 402 KB)