Graffiti Defense

Unwanted graffiti and wild stickers, posters and signs cause millions in economic damage every year in Germany alone. A specially developed silicone coating from WACKER can help keep cleaning costs low.

Graffiti artists usually work at night, spraying their often enormous creations – which they refer to as pieces – and their signature emblems – known as tags – on walls, fences and rail cars. They almost always do this without the consent of the property owner, whose only recourse is buffing – the term used within the graffiti scene for removing illegal pieces.

Egg-shell stickers are especially difficult to remove. They are the stickers and posters that often advertise events, and are usually found on relatively small objects like utility boxes and traffic signs.

The Association of German Cities estimates that the damage caused by illegal graffiti and wild posters costs the Federal Republic at least €200 million annually. In the United States, data provided by the Department of Justice indicate the cost of graffiti removal to be some twelve billion dollars per year. One of the most costly practices is known as bombing – when the perpetrator tries to spray as many simple characters as possible in a short period of time, emphasizing quantity over quality.

It follows that public and private property owners are looking for ways of keeping removal costs low. One option for them is a preventive treatment with a protective anti-graffiti system. Developed by Wacker Chemie AG, SILRES® BS 710 is a concentrated active agent for long-term graffiti prevention. At the 2017 European Coatings Show, the Group will be unveiling the product to a wide audience of professionals.

Most anti-graffiti systems form an unbroken film over the substrate to be protected. This film seals all of the surface pores and acts as a barrier between the substrate and the paint sprayed onto it.

This barrier layer keeps the spray paint from entering the pores of the substrate, thus preventing the graffiti from adhering well to the surface and making it easier to remove – the graffiti can then be washed off using a suitable cleaning agent, though both the cleaning method and the cleanser need to be appropriate to the coating in question.

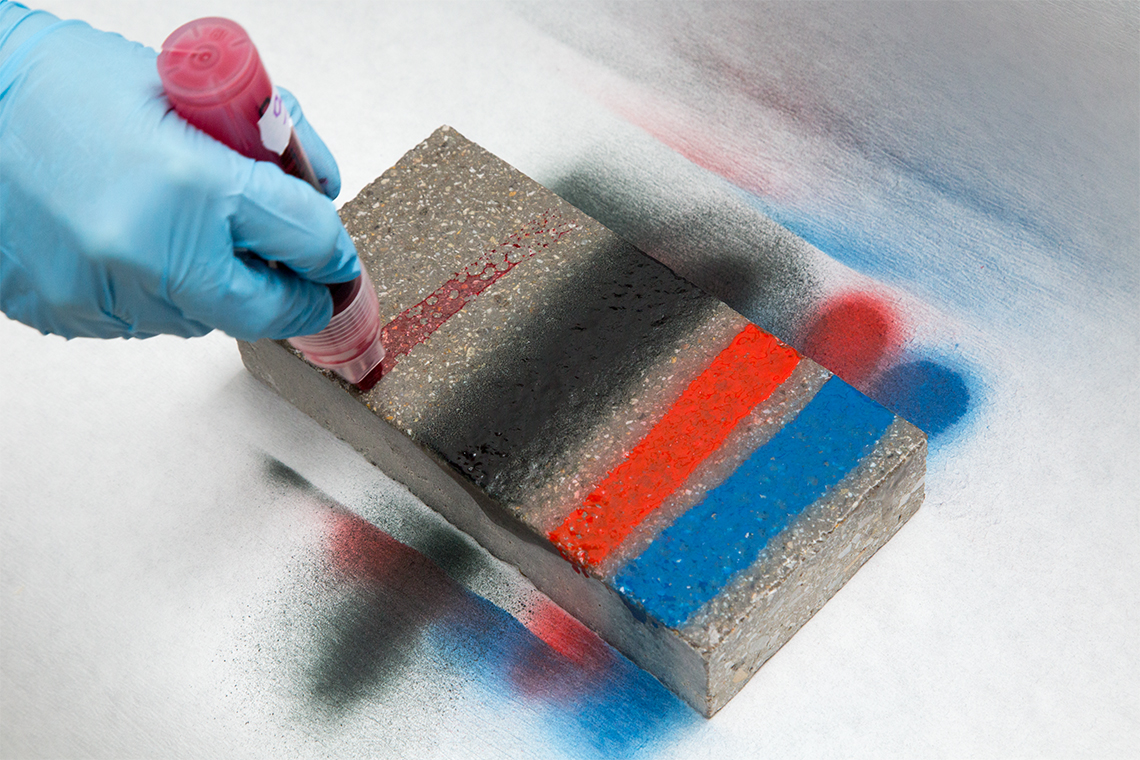

A technician sprays an unplastered test wall at the WACKER site in Burghausen using commercially available paint like those used by graffiti artists.

Anti-graffiti treatments can be broken down into three categories in terms of their durability: temporary, semi-permanent and permanent systems, which differ according to the behavior of the barrier layer when the graffiti is washed off. If the barrier remains fully intact and withstands at least 20 graffiti attacks, including the subsequent cleaning processes, the system is considered to be permanent. If, on the other hand, it washes off along with the graffiti, we speak of a temporary system or sacrificial coating. The longevity of semi-permanent systems lies between the two extremes.

The three classes of product each have their advantages and disadvantages (see page 5). “Temporary systems work to your advantage in cases where the building exterior needs to remain unchanged or if you don’t want to impede the exchange of moisture or permeability,” says Marianne Kreuzpointner, who is responsible for marketing the anti-graffiti coating at WACKER. “Both of those properties play an important role in preserving historic monuments.” The advantage of permanent systems, by contrast, is that they do not need to be reapplied for long periods of time, while still providing full protection against graffiti. “That’s a powerful financial argument,” Kreuzpointner underscores, “especially in areas where graffiti attacks are likely to occur over and over again.”

Attempting to clean the wall with a household sponge.

The new concentrated anti-graffiti agent from WACKER produces a permanent silicone coating. SILRES® BS 710 is a condensation-curing, RTV 1 silicone rubber compound – a one-component silicone rubber grade that undergoes a chemical condensation reaction at room temperature and upon exposure to atmospheric humidity to form a silicone elastomer. With a Shore A hardness of 37, SILRES® BS 710 is soft when cured, achieving an elastic elongation value of 130 percent.

RTV-1 coating materials typically contain an oxime curing agent and a tin catalyst. During the development of SILRES® BS 710, however, WACKER chemists led by Dr. Hartmut Ackermann worked out a new formulation concept: “We reverted to a silane crosslinker and a silane adhesion promoter that simultaneously functions as a catalyst for the crosslinking reaction,” Ackermann explains. “That meant we could dispense with the use of traditional components, which are harmful to human health. That’s a benefit to anyone who formulates the concentrate or applies a liquid coating material made from the concentrate.”

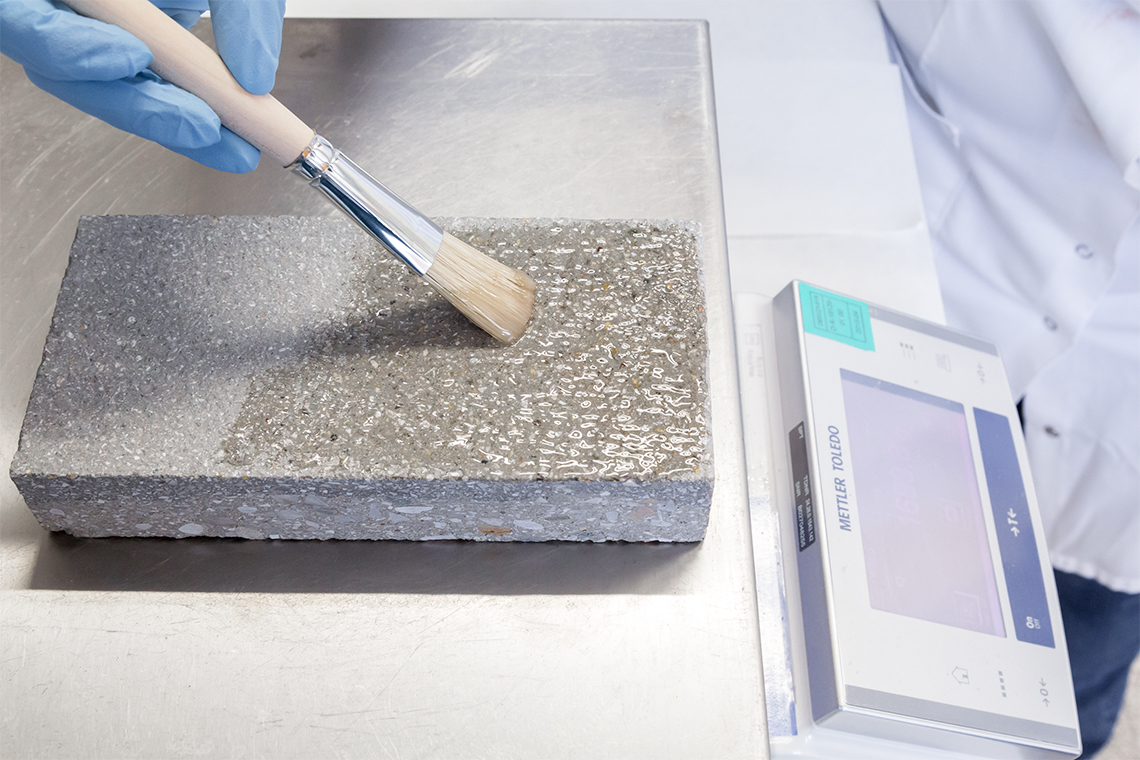

Brick walls treated with SILRES® BS 710 can be readily cleaned after a graffiti attack.

With a viscosity of 5,000 mPa·s, the concentrate is viscous, although it does thin when subjected to shear forces. The viscosity can also be reduced through the addition of an aliphatic solvent. Customers also have the option of adding pigments in order to color the compound. Manufacturers of building protection agents can easily incorporate SILRES® BS 710 into ready-to-use products, and have the freedom to adjust the active content, the viscosity and, if necessary, the hue to meet the needs of the application at hand. An important point to keep in mind when using SILRES® BS 710 as a transparent coating is that the product intensifies the color of the substrate and produces glossy surfaces.

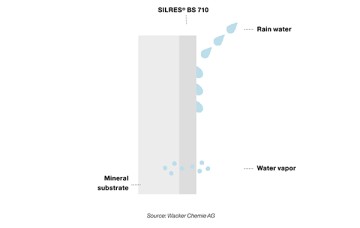

Which is below the sd value of traditional polyurethane coatings of equal thickness. Formulations based on SILRES® BS 710 are vapor permeable and do not block the moisture exchange through the building outer wall.

Good Adhesion on Concrete and Brick

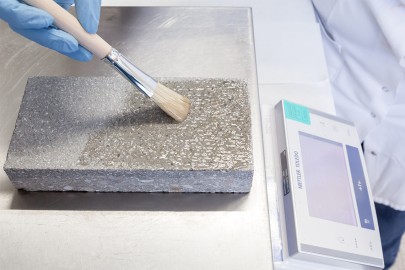

Not only is the concentrate easy to process – it is also quite simple to apply coating compounds made from SILRES® BS 710 as well: they can either be sprayed onto the substrate or spread on with a roller or brush.

The coating starts out as a liquid, but when exposed to atmospheric humidity, it cures from the outside in. The surface is no longer sticky after about four hours. A curing time of a day or more produces a strong silicone film that permanently bonds not only to many porous mineral substrates, but also to wood and epoxy resins – no need to treat the substrate with a primer ahead of time.

Adhesion tests have shown that the most suitable of these substrates are concrete, brick, plaster, sandstone, sand-lime brick and natural stone. The tensile adhesive strength of unprimed sand-lime brick, for instance, has been measured as 1.30 N/mm2 – a value frequently encountered in the construction materials industry for floor coatings on mineral-based substrates. Tests also showed that glass or painted metals need to be treated with a suitable primer in order to achieve the adhesion necessary.

“Thanks to SILRES® BS 710, the building protection industry now has a highly effective concentrate at its disposal for use in permanent anti-graffiti coating agents.”

Rudolf Hager, Head of the Construction Silicones business teamVapor Permeable with an Abhesive Surface

WACKER anti-graffiti protection is particularly suitable for infrastructure such as bridges, underpasses and subway stations.

A key property of silicone films made from SILRES® BS 710 is their exceptionally abhesive surface – a surface, in other words, to which other substances do not adhere well at all. As a result, graffiti can be washed off with cold water using a sponge or commercially available pressure washer – no special cleanser required – while posters and signs either fall off under their own weight or can be peeled off effortlessly.

Its abhesive properties are the result of the extraordinarily low surface energy of the silicone film. There are very few substances with lower surface tension, and, generally speaking, liquids are only able to wet and develop a strong bond to surfaces if the surface tension of the liquid is lower than that of the surface. This same principle applies to spray paints and to the adhesives used on stickers – the surface tension in each of these cases is significantly higher than that of silicone and, as a consequence, they do not adhere well to the silicone surface.

The application technology specialists at WACKER found that application of 200 to 250 grams of SILRES® BS 710 per square meter is enough to provide reliable protection against graffiti. If the material is prepared correctly, the surface only needs to be treated once – the cured silicone film will then completely cover the pores in the substrate. The coating nevertheless remains permeable to water vapor. This has been confirmed by the sd value determined for layers of the cured material (see below).

The sd value for samples roughly 200 micrometers thick – which corresponds to the recommended coating weight of 250 grams of SILRES® BS 710 per square meter – was measured as 0.3 meters (class II, mid-range), which is below the sd value of traditional polyurethane coatings of equal thickness.

Lasting protection

Coatings made from SILRES® BS 710 exhibit the typical durability of silicones: they are resistant to heat stress, remain flexible even in exceptionally cold conditions, and can withstand freeze-thaw cycles and rain simulations. Not even constant exposure to light and UV radiation can damage the silicone film, which remains elastic, does not yellow – even under prolonged UV radiation – and retains its abhesive properties.

All of this has been tested and confirmed under outdoor weathering conditions, in graffiti removal studies and in accelerated aging experiments conducted in the laboratory. Coatings continued to provide full protection against graffiti, even after 20 cleaning cycles, demonstrating that SILRES® BS 710 offers permanent protection. Cleaning studies showed that if a pressure washer is used, the pump pressure should not exceed 100 bar.

“Thanks to SILRES® BS 710, the building protection industry now has a highly effective concentrate at its disposal for use in permanent anti-graffiti coatings that can be customized for a variety of application processes,” points out Dr. Rudi Hager, who heads up the Construction Silicones business team. “Also, coating agents made of SILRES® BS 710 only contain a single component, which eliminates the risk of mixing errors when it’s applied.”

SILRES® BS 710 treatment makes tags, pieces, throw-ups, one-liners and rooftops easy to remove; even stickers can be effortlessly removed from treated surfaces. This WACKER active, in other words, is doing its part to limit the financial and social consequences of graffiti and to stem the flood of unwanted stickers.

sdVALUE

The sd value – the diffusion-equivalent air layer thickness – describes the resistance of a material sample to the diffusion of water vapor. This value indicates how thick a resting layer of air must be to produce the same level of resistance to water-vapor diffusion as the material sample, given the temperature is the same. The sd value is given in meters. A low sd value indicates a high level of permeability to water vapor. According to DIN 7783, a layer of SILRES® BS 710 that is 200 micrometers thick exhibits class II permeability characteristics (average: >= 0.14 to < 1.4 m). An sd value of < 0.14 m describes a high degree of permeability to water vapor. If the sd value is >= 1.4 m, the material is categorized as being extremely impermeable to water vapor.

SILRES® BS 710 in Tests on a Variety of Substrates

Graffiti Prevention: temporary, permanent or semi-permanent

The protective film produced by temporary systems consists of waxes, biopolymers or acrylates. These materials do not prevent water vapor from migrating out of the substrate and into the ambient air and they are invisible, which is why they can be used on registered historic landmarks. The disadvantage of these systems is that the protective film has to be completely reapplied after cleaning off the graffiti; even without graffiti attacks, these coatings only last a few years.

The major advantage of permanent anti-graffiti systems is that they remain intact when the graffiti is cleaned off and can last many years without losing their ability to protect the surface. The downside, however, is that they usually affect the appearance of the substrate. In addition, the coatings of many traditional permanent systems are so dense that water vapor cannot penetrate them. If a coating that inhibits diffusion in this way is applied on a damp substrate, the moisture inside will not be able to escape. The protective film then comes off in some places as a result, potentially causing blisters to form or the paint to flake off; moisture damage to the building fabric is a possibility as well – a problem that does not arise with SILRES® BS 710. Traditional permanent coatings are based on substances such as polyurethanes, epoxy resins and fluoropolymers.

In semi-permanent coatings, only one component of the film is lost during cleaning rather than the entire film itself. The substrate has to be treated again every time graffiti is removed and at intervals of three to five years. The advantage of semi-permanent coatings is that they are virtually undetectable to the eye and are permeable to water vapor. These products often consist of blends of organic waxes, silanes and siloxanes.

Further information

Our product portal will give you all the technical details about SILRES® BS 710.

Product Page