Resin modification for composites

WACKER offers additives, co-catalysis and auxiliaries for high- and low-temperature processes. We are also your expert partner for any questions you may have regarding formulations, offering technical support for all resins commonly used in the production of thermosets, such as unsaturated polyesters (UP), vinyl esters (VE), phenols, epoxides (EP), melamine and polyurethanes (PU).

Low-profile additives

VINNAPAS® solid resins (polyvinyl acetate) reduce shrinkage in unsaturated polyester (UP) and vinyl ester (VE) resins, making it possible to produce composite parts of consistently high quality with smooth, homogeneous surfaces. WACKER’s portfolio includes carboxylated and carboxyl-free VINNAPAS® resins in a wide range of viscosities, as well as specialty vinyl laurate/vinyl acetate copolymers. The resins dissolve readily in styrene and (meth)acrylic monomers; solutions can even be produced at room temperature. VINNAPAS® can therefore be used in a wide variety of formulations and processes.

Advantages:

Applications:

The following composite production processes:

Additives for rheology control

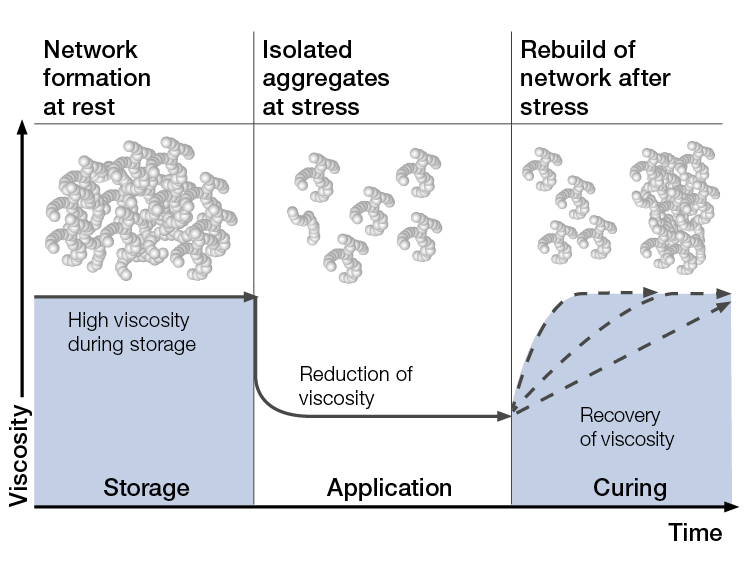

When HDK® is used in resin formulations, electrostatic reactions result in a three-dimensional network that gives the product a gel-like viscosity. Shear forces – such as those generated during coating – cause this network structure to collapse, and the viscosity suddenly decreases (shear thinning). When at rest (following application), the HDK® network reforms and the viscosity increases once again (thixotropy).

HDK® pyrogenic silica can be used for controlling flow properties. In resin formulations, it increases shear thinning, has a thixotropic effect and, as such, improves fiber wetting and impregnation. Optimum thixotropy keeps gel coats formulated with HDK® from running.

Thanks to its broad, application-specific portfolio of HDK® products, WACKER offers customized solutions for an exceptionally wide range of composite formulations.

Advantages:

Applications:

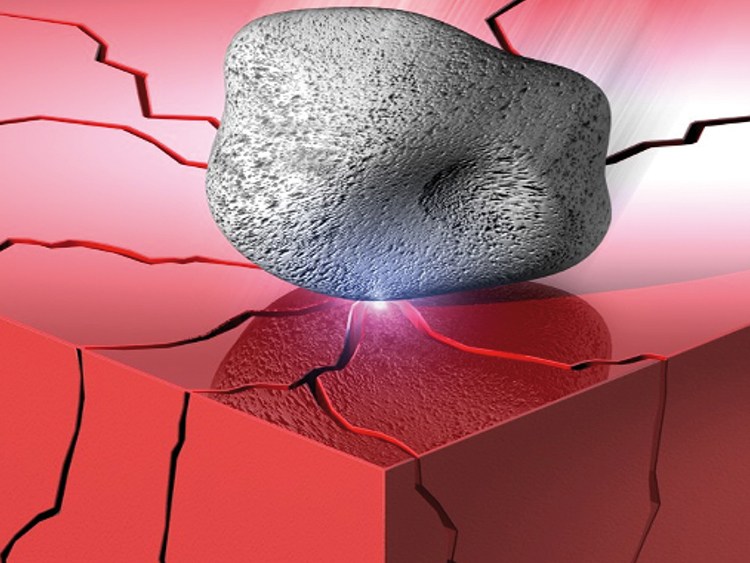

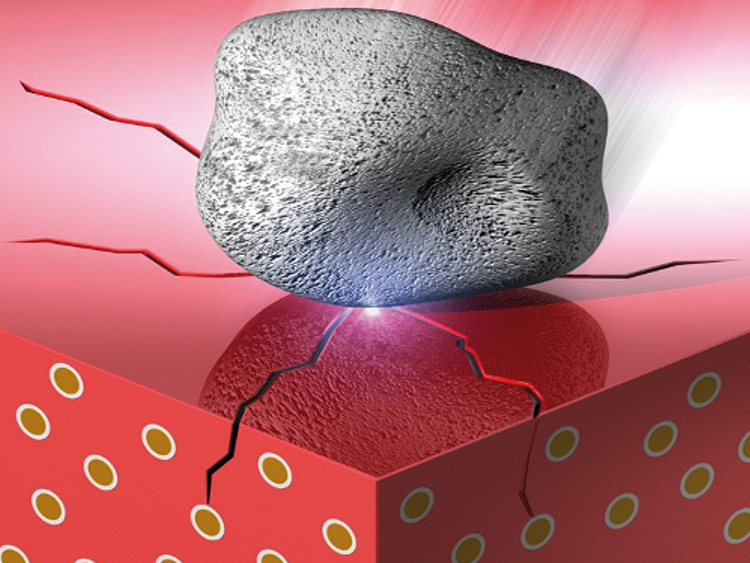

Dispersible impact modifiers

GENIOPERL® organosilicone copolymers serve as impact modifiers, increasing the durability of otherwise brittle thermoset resins such as epoxides and vinyl esters without compromising their mechanical strength or resistance to heat. GENIOPERL® products distribute evenly in the resin matrix. Their unique structure makes these copolymers compatible with thermosetting resins, yielding a stable, fine dispersion and thus delivering superior efficiency.

Advantages:

Applications:

The following composite production processes:

Additional information

Brochures

VINNAPAS® Solid Resins | Low Profile Additives for Composites

DownloadELASTOSIL®, GENIOPERL®, GENIOSIL®, HDK®, VENTOTEC®, VINNAPAS® | Solutions for Composites

DownloadVINNAPAS® LL 8251 | Low Profile Additive for Composites

DownloadVINNAPAS® Solid Resins | Overview and Portfolio

DownloadComposite Industry | Low-Profile Additives | VINNAPAS® eco

Download