Scratch-Resistant and Cost-Effective

Modern car interiors are dominated by plastics. For cost reasons, small cars, in particular, often contain parts made of polypropylene, which scratches easily. However, if GENIOPLAST® Pellet S – a silicone additive from WACKER – is added to the plastic, there is a good chance that its surface will maintain its appearance even after long and intensive use.

Buying a car is a highly emotional affair. The buyer first looks for an attractive exterior design and then focuses on the car’s interior. People spend so much time in their cars nowadays that the interior needs to be comfortable and have a high-end look and feel. In upper midsize and full-size cars, manufacturers rely on elaborately foamed and decorated plastics or expensive materials such as leather and burl wood to achieve the optical and haptic qualities desired by customers.

The lower down potential buyers move in the model hierarchy, however, the more price conscious they become. The car interior is one of the few areas where manufacturers can cut costs without compromising functionality or safety. That’s why, for the interior trim of compact and small cars, they use many parts based on materials which are considerably less costly to make – talc-filled polypropylene, for example, is the cheapest plastic suitable for interior applications. Parts made of this plastic material scratch easily and can quickly become unsightly in use. That’s why automakers are looking for cost-effective ways of giving the polypropylene parts a surface that keeps its high-quality and attractive appearance.

Matt and Reflection-Free

Foamed plastics and imitation leather finished with additives ensure that the appearance and texture of a car interior convey the desired high quality.

Interior plastic parts made of talc-filled polypropylene are hard and their surface looks matt. Typical examples include the lower part of the dashboard, the glove compartment’s cover, the panels below the door handle, the pillar trim and the housing of the center console. The surface is matt for several reasons, as Dr. Michael Geck, applications engineer for WACKER’s plastic additives segment, explains: “Matt plastic surfaces have a velvety feel, look good and avoid light reflections that could irritate or dazzle the driver.”

However, the more matted such surfaces are, the more susceptible they are to scratches and abrasion. For example, sharp-edged ignition keys can quickly leave shiny scratches when they scrape a polypropylene dashboard. Even blunt objects can leave traces. Running a fingernail over the matt plastic surface produces a shiny streak – the nail polishes the surface. Experts refer to this as mar resistance or marring. If your knee repeatedly rubs against the same section of a door panel when you get in and out of a car, you will leave a mark – the affected section of the surface will look worn. Plastics processors have at their disposal numerous methods that give inexpensive plastic a high-quality look. They can, for example, back-foam the hard material, coat it with a thermoplastic elastomer, paint it or decorate it with hot stamping foils. However, all of these methods make the parts considerably more expensive.

Low Surface Friction

Compounding and Injection Molding at WACKER’s Polymer Pilot Plant

WACKER’s Burghausen site operates a polymer pilot plant, which is used by all corporate sectors that deal with organic polymers and silicones. Here, WACKER pools product and applications expertise in order to test new products in an application-oriented manner, tailor customer-specific products to the required property profile and offer customers comprehensive technical service – from technical support to trouble shooting. The pilot plant is equipped with the kinds of production and test facilities commonly used in the plastics industry. For application-related work on organic plastics, for example, there is a twin-screw extruder (Berstorff ZE 25) and an injection-molding machine (Engel ES 600/125).

The twin-screw extruder is used for compounding because it can optimally mix all the constituents of a polymer compound. This machine was also employed to make the polymer compounds that were used to test the effects of the GENIOPLAST® Pellet S silicone additive. The injection-molding machine processes the compounds into plastic parts, including the test panels that are required for many of the applications tests. The pilot plant’s test laboratories offer an opportunity to determine key properties of the plastic, for example its hardness, its mechanical properties and the flow properties of its melt.

An easier and cheaper alternative is for the compounder – the manufacturer of the ready-to-use polymer compound – to modify the surface properties of the plastic with the aid of an additive. With GENIOPLAST® Pellet S, WACKER has now marketed a highly effective silicone additive that has no undesired side effects and remains active throughout the vehicle’s entire service life.

Additives such as GENIOPLAST® Pellet S improve the scratch and abrasion resistance of a plastic by reducing its surface friction. “When surface friction is relatively low, objects slide over the plastic surface more easily, leaving fewer visible marks,” explains Dr. Geck.

However, conventional additives have considerable deficiencies and side effects, which are tolerated less and less, especially in the automotive sector. Organic antifriction agents, for example, have an unpleasant odor and migrate out of the plastic over time. They condense on the inside of the windscreen as a greasy film – a phenomenon that is known in the industry as fogging. Furthermore, the antifriction agent that escapes from the plastic surface creates an unpleasant feel – test persons describe the surface as rubbery.

Masterbatch with Pellets

Silicone fluids, another well-established class of antifriction agent, are odorless and can easily withstand high temperatures, but tend to exude from the plastic even more than organic grades. Manufacturers reacted to this by launching ultra-high-molecular silicone polymers. These kinds of polymers essentially do not migrate due to their high molecular weight. However, they are so highly viscous that it’s virtually impossible to incorporate them into thermoplastic compounds. Silicone masterbatches, which have been available since the late 1990s, solved this handling problem. They are easy to incorporate because they consist of solid pellets. But masterbatches do have a drawback: compounders must keep a specific additive masterbatch in stock for each thermoplastic that is to be modified with the additive.

This was Dr. Geck’s starting point for the development of GENIOPLAST® Pellet S. His aim was to develop a highly effective and easy-to-process silicone additive that would be universally suitable for all thermoplastics. “There was no doubt that the active ingredient would be an ultra-high-molecular silicone. What proved to be difficult, however, was transforming it into an easy-to-process, solid product form,” says Dr. Geck, remembering the challenges encountered during the development phase.

High Active-Ingredient Content

Petra Stinglhammer from the applications lab performs a scratch-resistance test on plastic materials finished with GENIOPLAST® Pellet S.

The formulation of the active into a pelletized product was a success. The resulting additive takes the shape of small, cylindrical pellets, which can be incorporated into the polymer compound without difficulty. The pellets contain a pyrogenic silica that serves as the carrier for the silicone active, which makes up 70 percent of the pellet weight. This high active content makes the additive efficient.

According to applications engineer Geck, the carrier contributes significantly to the additive’s favorable properties: “Firstly, the pyrogenic silica is responsible for the firm consistency of the additive. Since, secondly, it is compatible with all thermoplastics, compounders only require a single silicone additive to optimize a range of different thermoplastics – a big advantage over silicone masterbatches. Thirdly, the silica anchors the active ingredient in the polymer matrix.” The silicone active thus has no way of migrating out of the modified polymer.

Applications testing began once the first additive samples had been made. With talc-filled polypropylene compounds as the base, the silicone pellets had to prove their effectiveness and feasibility and undergo comparison with commercially available competitor products. Numerous tests were carried out with respect to possible side effects, too. Dr. Geck used one organic additive and two silicone-based competitor products for the comparison.

The testing performed by the applications labs was supplemented by trials run in WACKER’s polymer pilot plant (see box on page 2). “This gave us the chance to manufacture the test polymer compounds ourselves – in exactly the same way that compounders do – and to process them with an injection-molding machine. We also produced the test panels that we needed for our trials in this way,” reports Dr. Geck. A standard talc-filled polypropylene formulation served as the base – the additives to be tested were added to it in different amounts. The test panels’ surface quality was tested and assessed according to industrial standards, especially car manufacturers’ specifications.

Much More Resistant to Scratches and Abrasion

The scratch test (see box on right) simulates scratching with a sharp-edged ignition key. The test is performed using a scratch hardness tester equipped with a test needle. The resultant scratches are subsequently inspected more closely. If the test needle is replaced with a test disc, the device measures the mar resistance. Here, the marks are assessed with the aid of a glossmeter. Another test device, the linear tester, performs the crockmeter test (see box on next page), imitating the abrasive effect of clothing.

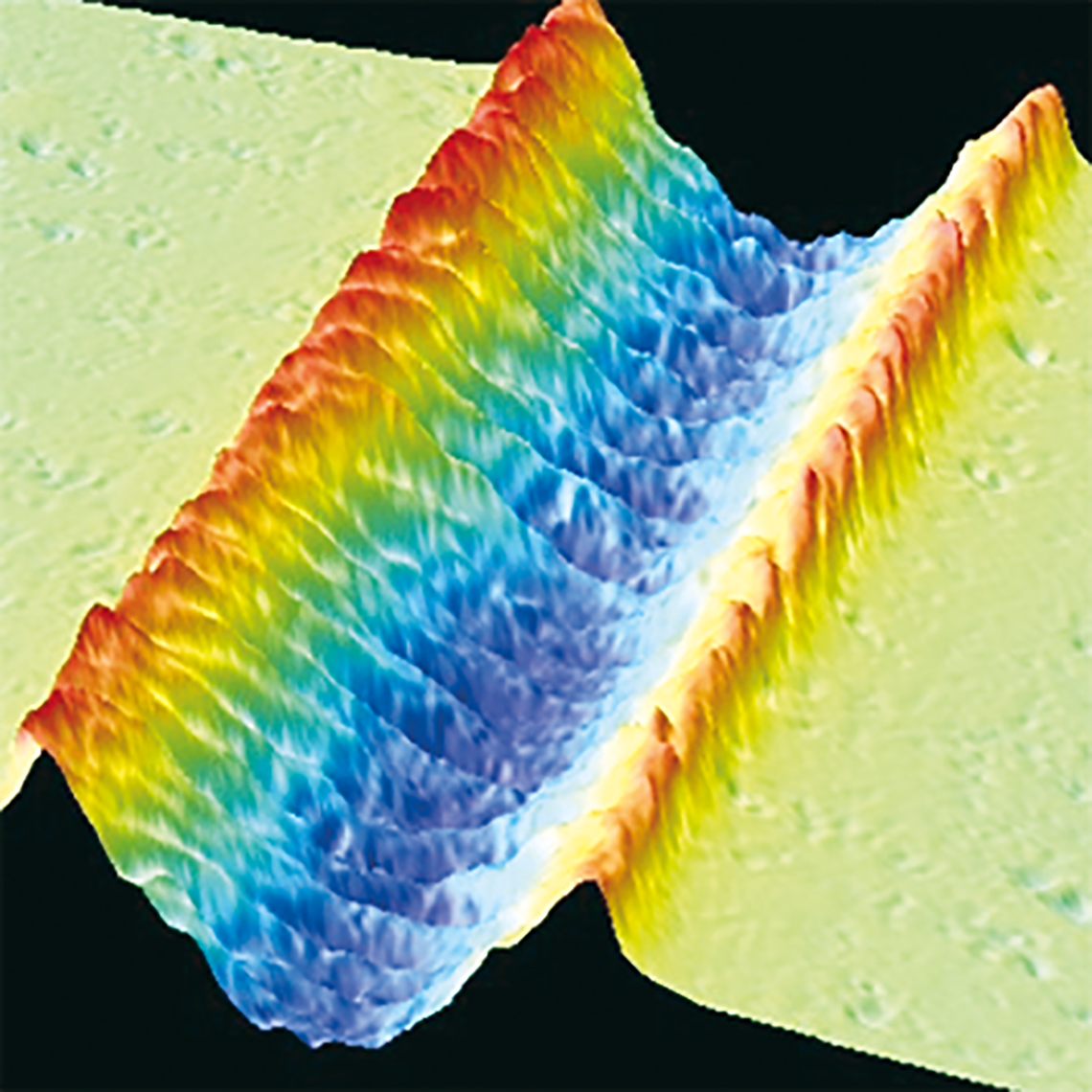

A comparative inspection of the scratch marks with ones on unmodified plastic is particularly informative. A confocal microscope clearly shows that the scratches are less deep and rough in the plastic that has been modified with GENIOPLAST® Pellet S – even when the test panels were stored at 80 °C for a week. Consequently, the scratches should scatter incident light less strongly and thus appear less bright. This assumption is confirmed by the second method for testing the scratch marks – the brightness measurement: the scratched areas are less bright than the intact areas, making the scratches less noticeable.

Scratch Hardness Tester

Erichsen’s 430 P-I scratch hardness tester is widely used. This versatile device makes straight, parallel cuts in plastic and coated surfaces. To do so, a tool is guided over the surface – such as the test panel made of the plastic to be tested – with a precisely adjusted force. The test panel is clamped into the device. A suitable tool – for example a test needle or a test disc – is then selected and the force adjusted. The device can run several different test programs.

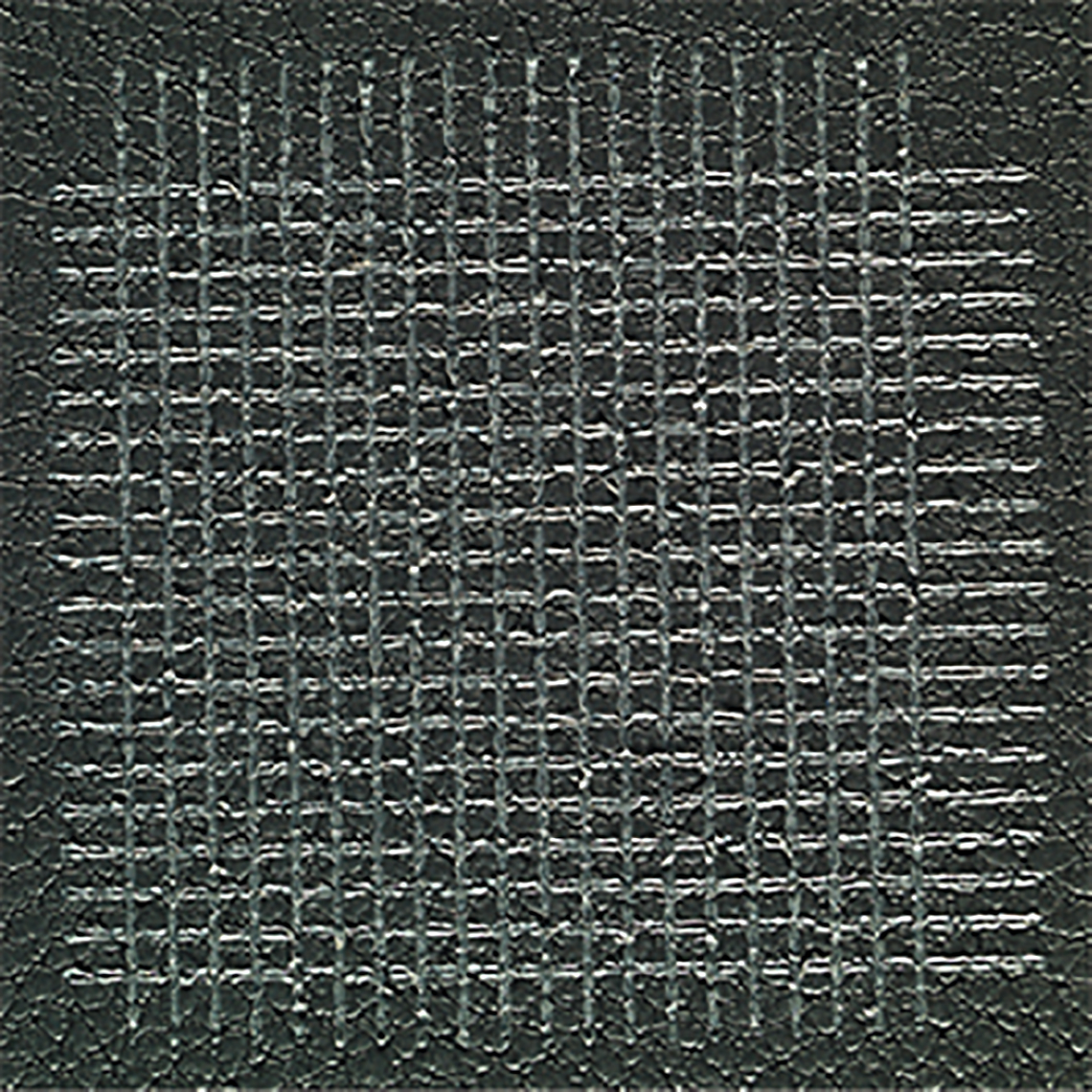

A test needle is used to perform the scratch test. Turning the test panel by 90 degrees after an operating cycle and clamping it in again yields a grid pattern of shiny scratch marks. The marks are subsequently inspected more closely. The difference in brightness between the dark intact areas and the shiny damaged areas is routinely measured with a color and gloss meter. The shinier the scratches as compared to the intact surface, the more easily the tested surface scratches. For more extensive testing, the scratches can additionally be examined microscopically, for example to thoroughly study their contours, depth and roughness inside the groove.

A round-edged test disc is used to test mar resistance based on General Motors Europe (GME) specifications. Similar to an upright coin, this disc bluntly scrapes over the plastic surface in straight, parallel lines. Since the lines are close together and the resultant marks overlap, the stress is on a rectangular section of the surface. This section has a different gloss to the rest of the surface. A surface that was originally matt will be shinier after the treatment than before, taking on a polished appearance, because the scraping levels out the microstructure that produced the matt surface character. Conversely, if the surface was originally smooth, its gloss is reduced. The change in gloss is measured with a color and gloss meter. The more the gloss changes, the more pronounced the undesirable surface change that is described as marring.

WACKER chemists Dr. Klaus Pohmer and Dr. Michael Geck, together with development engineer Oliver Fuhrmann (from left), use an interior trim to demonstrate how silicone additives increase the scratch resistance of plastic.

The results of these and further tests show that GENIOPLAST® Pellet S reduces the plastic’s surface friction, thus improving the scratch and abrasion resistance. Furthermore, this does not adversely affect the plastic’s mechanical properties. “On the contrary, tensile strength and stiffness are actually enhanced,” reports Dr. Klaus Pohmer, who is in charge of global business development at WACKER SILICONES’ Performance Silicones business unit. He explained that the tests also showed that the modified plastic did not become tacky when exposed to ultraviolet light. That’s why interior parts made of modified polypropylene still feel good even after intense exposure to sunlight.

GENIOPLAST® Pellet S performed very well in the fogging test – as did the two silicone-based competitor products – whereas the organic additive displayed considerable weaknesses here. Unlike the organic additive, the long-chain silicone does not migrate out of the polymer, even at high temperatures. Thanks to the WACKER product, unpleasant odors and blooming of the active, as well as its undesirable deposits on the windscreen, are finally a thing of the past.

“The challenge was to transform an ultra-high-molecular silicone into an easy-to-process, solid product form.”

Dr. Michael Geck, Application TechnologyCrockmeter Test

The crockmeter test involves a test probe covered with a cotton cloth rubbing the same section of a test panel (made of the test plastic) several times with a specific force. The frequency of the test probe’s back-and-forth movement during the test and its downward force can be adjusted on the test device. The test panel is subsequently inspected visually. If the surface of a dark test panel is very sensitive to the repeated rubbing, the stressed area takes on a shiny appearance; if it is not sensitive to the rubbing, its appearance is unchanged. Erichsen’s Lineartester 249 is used as the test device. The test panels made of plastic modified with GENIOPLAST® Pellet S performed best in this test, while those with the organic competitor product were the worst performers.

“Since our additive makes plastic surfaces considerably more scratch and abrasion resistant, they look almost as good as new in a car’s interior even after long and intensive use,” sums up Dr. Pohmer. “In this way, automakers can easily and cost-effectively create more added value for their interior parts.” Parts made of talc-filled polypropylene that has been modified with GENIOPLAST® Pellet S can already be found in several manufacturers’ car interiors. European – especially German – and South Korean car manufacturers are pioneers here. However, the silicone pellets are also creating interest in the US automotive industry.