At the world’s largest tradeshow for plastics and rubber, the Munich-based chemical group will be showcasing its innovations under the motto “Thinking Beyond” at booth A10 in hall 6. On an area of 300 square meters, a multitude of novel products will be awaiting visitors, ranging from thermally conductive silicones for battery cooling in electric vehicles, flame-retardant silicone rubber for rolling stock and self-adhesive silicones with low-friction surfaces to electroactive silicone laminates for actuators and sensors.

“Silicones are extremely versatile and effective. They are essential for novel product solutions and belong to the innovation drivers in key industry sectors such as automotive, medical, and electronics,” says Robert Gnann, head of the WACKER SILICONES business division. “Silicones are therefore more and more sought after in many industries. Future technologies such as e-mobility and digitalization, global efforts to increase the standards of living and health and realizing the sustainability goals of the European Union and the United Nations will hardly be feasible without high-performance materials such as silicones.”

The rise in product and industry specifications also presents a major challenge to manufacturers. “Some standard materials can no longer keep pace with this development,” said Christian Gimber, Vice President Engineering Silicones at WACKER SILICONES. “That is why more and more companies are counting on silicone elastomers. Thanks to their outstanding mechanical and chemical properties, silicones have become indispensable for solving demanding technical problems and developing and implementing innovative technologies.”

WACKER Booth to Cover Eight Topics

At this year’s trade show, WACKER’s booth will be covering eight topics. One of these will focus on the advantages of liquid silicone rubber that contains very few volatile components. Since early 2019, this applies to ELASTOSIL® LR 3xxx, ELASTOSIL® LR 6xxx and SILPURAN® 6xxx silicones manufactured in Europe. Thanks to ultra-modern process technologies, WACKER has managed to slash the content of volatile Dx siloxanes in its liquid silicone rubber by at least 90 percent. By upgrading the LSR portfolio in this way, the company is enabling manufacturers of silicone parts to meet regulatory requirements and industry as well as customer needs more readily and reliably than ever before. WACKER’s initiative is setting new industrial standards worldwide.

The ELASTOSIL® LR 5040 product line shows what is possible and what advantages the new standard offers. These high-performance silicones cure to form elastomers that possess the same mechanical properties without thermal treatment as a product that has been post-cured. Users can skip the lengthy and costly process step of post-curing altogether. Due to their high purity, parts made of ELASTOSIL® LR 5040 are suitable for food-contact applications and can be used in line with the recommendations of the German Federal Institute for Risk Assessment (BfR) and the US Food and Drug Administration (FDA). They also meet the criteria of selected biocompatibility tests in ISO 10993 and US Pharmacopeia (Class VI).

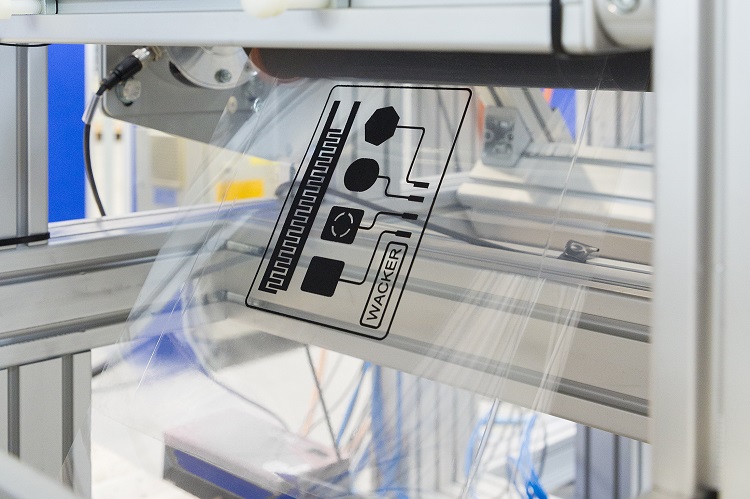

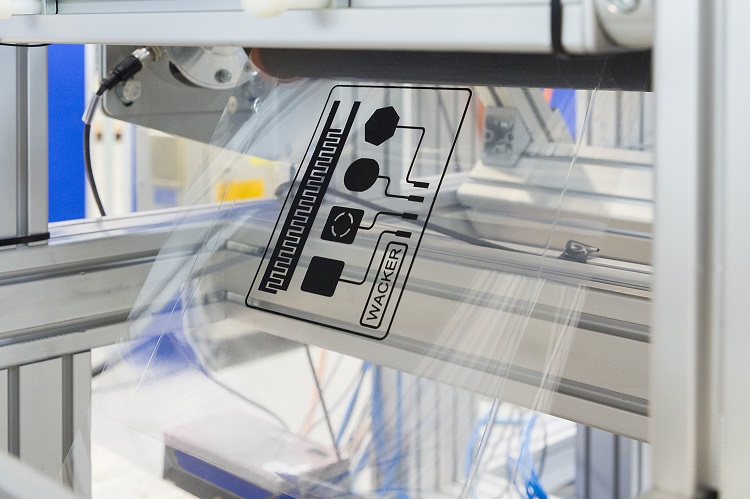

ELASTOSIL® LR 5040 will also be at the center of this year’s injection-molding demonstration at the WACKER booth. Here, food-contact parts will be produced out of the liquid silicone rubber during