K 2019: 21st International Trade Fair for Plastics and Rubber - WACKER Introduces High-Performance Additive for Thermoplastic Elastomers

Munich, Jul 18, 2019

WACKER, the Munich-based chemical company, will showcase a new silicone additive for thermoplastic polyurethanes (TPU) at the K 2019 International Trade Fair for Plastics and Rubber. Sold under the name GENIOPLAST® Pellet 345, the additive lowers the hardness of TPUs, while boosting their elasticity and enhancing their properties. The surfaces of molded parts modified with the additive are pleasantly soft to the touch and more resistant to scratches, abrasion and contamination. The new additive is readily incorporated into thermoplastic polyurethanes and has fewer undesirable secondary effects than conventional silicone products. K 2019 takes place in Düsseldorf, Germany, from October 16 to 23.

GENIOPLAST® Pellet 345 complements WACKER’s portfolio of silicone-based additives for the compounding of thermoplastic polymers. The product has been specifically developed with thermoplastic polyurethanes (TPUs) in mind, but can be used for modifying other thermoplastic elastomers as well. For example, the product, which is supplied in pellet form, can markedly boost the properties of thermoplastic polyamide and copolyester elastomers.

GENIOPLAST® Pellet 345 is a silicone copolymer and is processed like a thermoplastic. Organic polymer segments contained within GENIOPLAST® Pellet 345 make it so compatible with thermoplastic polyurethanes that, unlike conventional silicones, it disperses very finely and homogeneously throughout the polyurethane matrix. The copolymer becomes physically bound to the matrix and is therefore unable to migrate. In Europe, GENIOPLAST® Pellet 345 is authorized for food-contact applications.

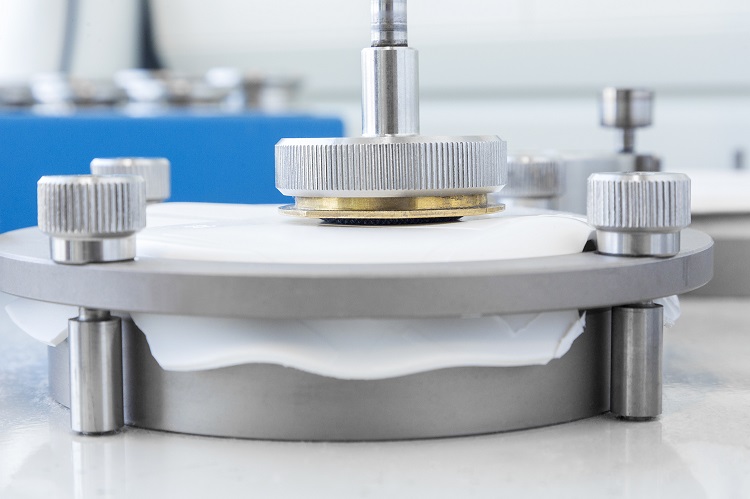

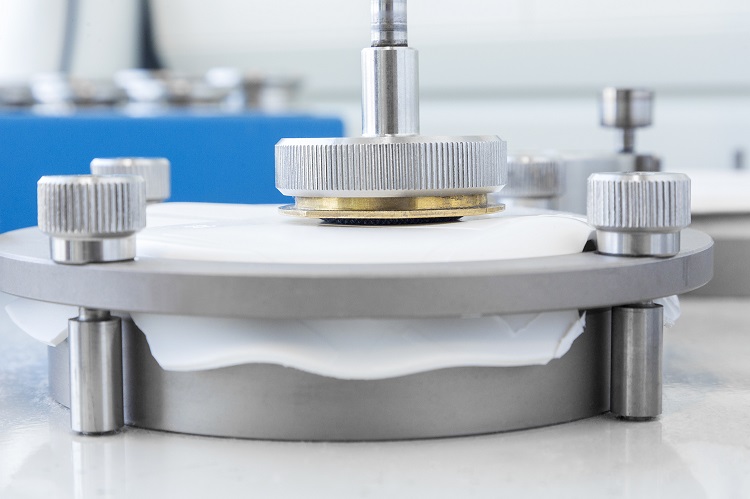

Adding GENIOPLAST® Pellet 345 boosts the surface smoothness of thermoplastic polyurethanes, thereby enhancing their scratch and abrasion resistance. Moreover, surfaces become more resistant to contamination by foodstuffs and cosmetics. These effects are achieved at additions of just 3 to 5 percent.

Adding more than 10 percent to a thermoplastic polyurethane elastomer affects its hardness and mechanical properties, rendering it softer and more elastic. For every 10 percent rise in amount added, the hardness drops by roughly 5 points on the Shore A scale. As the polymer softens, it necessarily loses some of its mechanical strength. However, this undesirable secondary effect is less pronounced with GENIOPLAST® Pellet 345 than with other silicone-based technologies routinely used to soften TPU polymers.

A characteristic feature of plastic articles made with blends of TPU and the new additive is a silky-soft surface with a dry feel. This is precisely the type of surface which end users expect of articles which they frequently touch or wear .

The additive pellets are easy to meter, and incorporating them into thermoplastic polyurethanes on conventional compounding extruders is straightforward. The resulting compounds can then be injection molded and extruded to parts and film respectively. The compounds also lend themselves to two-component injection molding because the additive does not interfere with the good adhesion properties of the polymer. This means it is possible to cost-effectively produce hard/soft combinations in which the soft component has a particularly pleasant feel.

By virtue of this property set, GENIOPLAST® Pellet 345 has extended the range of applications for thermoplastic polyurethanes. There is considerable demand in the entertainments, microelectronics and sports equipment sectors for molded TPU parts that have a pleasant feel and retain their looks upon protracted use. Typical examples are wrist-straps for smart-watches and other wearables, smartphone covers that resist abrasion and discoloration, and soft grips for sports equipment and tools.

More information available at www.wacker.com/k2019.