Polymer binders for plasters

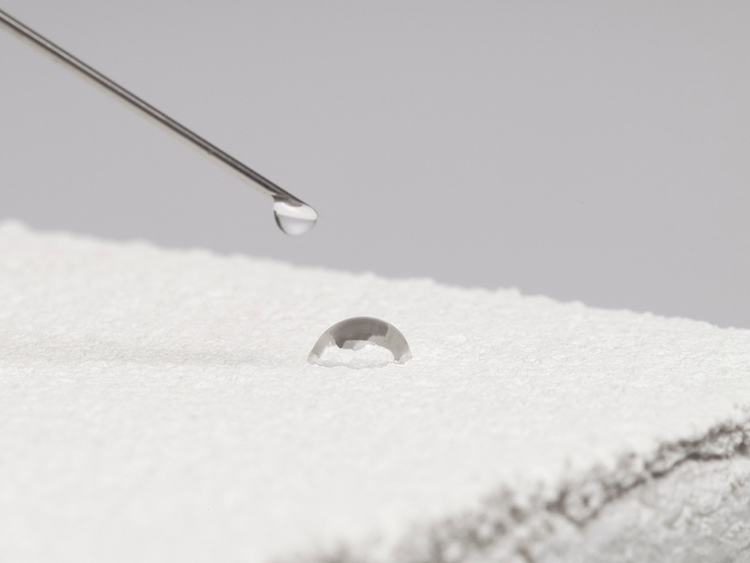

Hydrophobicity is a crucial factor in improving resistance to the elements.

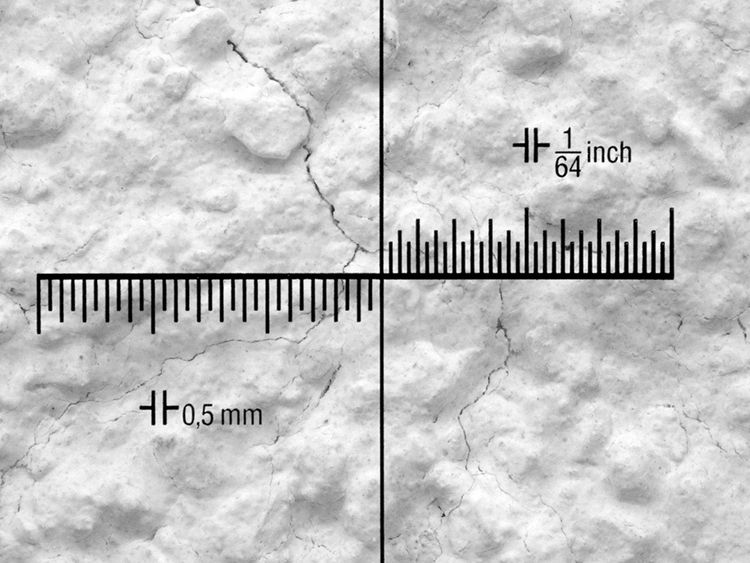

Plasters are constantly under attack from heat, cold, moisture and mechanical stress. These forces can cause cracks, algae growth and mold, leading to expensive repair work.

Our VINNAPAS® polymeric binders reliably prevent all that, actively inhibiting damage by improving important plaster properties such as workability, adhesion, flexibility, mechanical resistance, hydrophobicity and resistance to weathering. What’s more, as a component of a thermal insulation render (TIR) or an external thermal insulation composite system (ETICS/EIFS), they also make facades more energy efficient.

Modern plasters – challenges and solutions

Typical challenges:

Our solution:

VINNAPAS® polymeric binders form flexible bridges during the setting process. These bridges link the inorganic components of the plaster to form a durable matrix, thereby enhancing cohesion and adhesion, both within the plaster as well as between the plaster and substrate. At the same time, they also make plasters more elastic and impact resistant, which can offset stresses, such as those produced by temperature fluctuations.

Polymeric binders also improve hydrophobicity, reduce water absorption and dirt build-up, thus making the plaster more resistant to the elements and longer lasting.

Plaster FAQs

What advantages do VINNAPAS® binders offer in plasters?

VINNAPAS® polymer dispersions and dispersible polymer powders improve flexibility, adhesion and hydrophobicity in interior and exterior plasters, thus significantly reducing crack formation, moisture damage and algae growth. In addition, VINNAPAS® binders optimize the processing properties of plasters.

How do WACKER binders affect the energy efficiency of facades?

As an essential component of thermal insulation renders (TIRs), WACKER binders help optimize the energy efficiency of facades. If used in an external thermal insulation composite system (ETICS), they improve adhesion between the layers, thereby enhancing the stability and longevity of the system as a whole.

What types of plasters work well with VINNAPAS® products?

WACKER offers solutions for mineral plasters, dispersion-bound plasters, skim coats and thermal insulation renders. These products optimize dry-mix mortar formulations and ready-to-use systems in interior and exterior applications.

Why add binders to skim coats?

In addition to improving skim coat adhesion to concrete, lightweight concrete, cement fiberboard and other substrates, VINNAPAS® polymeric binders also optimize flexibility, prevent cracking and improve paint adhesion.