Electronics

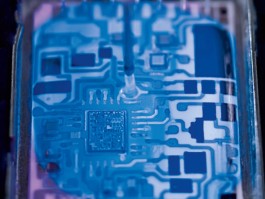

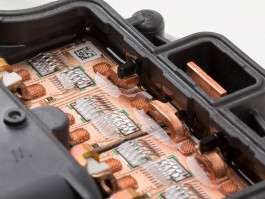

Room-temperature vulcanizing silicone elastomers from WACKER reliably protect against external influences, which ensures the functional safety of electrical and electronic components. As one of the world’s leading silicone manufacturers with many years of experience, WACKER is a competent partner of the industry and offers tailor-made solutions for potting, bonding, sealing and coating.

Brochures

SEMICOSIL® 976 Series Silicon-Gapfiller for Automotive Applications

DownloadSEMICOSIL® 811 | Adhesives for Electrics & Electronics

DownloadSEMICOSIL® 961 TC | Thermally Conductive Gap Filler for Electronics & Electrical Materials

DownloadSEMICOSIL® 871/1K TC | Thermally Conductive Adhesive for Electrics & Electronics

DownloadSEMICOSIL® 962 TC

DownloadELASTOSIL® SEMICOSIL® WACKER SilGel® | Low Volatile Silicones for Automotive Applications

DownloadELASTOSIL® SEMICOSIL® WACKER SilGel® | E-Mobility: E-Novation for Sensors and Ecus

DownloadELASTOSIL® LUMISIL® WACKER SilGel® SEMICOSIL® | E-Mobility: E-Novation for Automotive Displays

Downloade-Novation for Batteries Powered by Silicones

DownloadELASTOSIL® | Silicones for Cables and Connectors

DownloadSILRES® H62 C | Silicone Resin for Vacuum Pressure Impregnation

DownloadSilicones | e-Novation for e-Mobility

DownloadSEMICOSIL®, WACKER SilGel®, ELASTOSIL® | Silicone Gel Solutions

DownloadLUMISIL® UV Series | Silicones for Optical Bonding

Download