Our system has noticed that you are based in , but the current country setting is . Select country

3rd China International Supply Chain Expo (CISCE): WACKER Showcases Innovative Materials for New-energy Vehicles

WACKER will make its first appearance at the 3rd China International Supply Chain Expo (CISCE), where it will showcase an extensive portfolio of products for the automotive and electronics sectors. The company will unveil four breakthrough innovations, including a flame-retardant material for busbar protection in new-energy vehicles (NEV), a high-performance thermal interface material for automotive chip IC packaging and heat transfer, and a thermally conductive silicone rubber solution for NEV charging systems. Additionally, WACKER will launch a silicone-based immersion cooling fluid technology developed for Chinese customers. This cutting-edge solution meets the growing demand for efficient thermal management in cloud computing and data centers while helping to reduce operating costs.

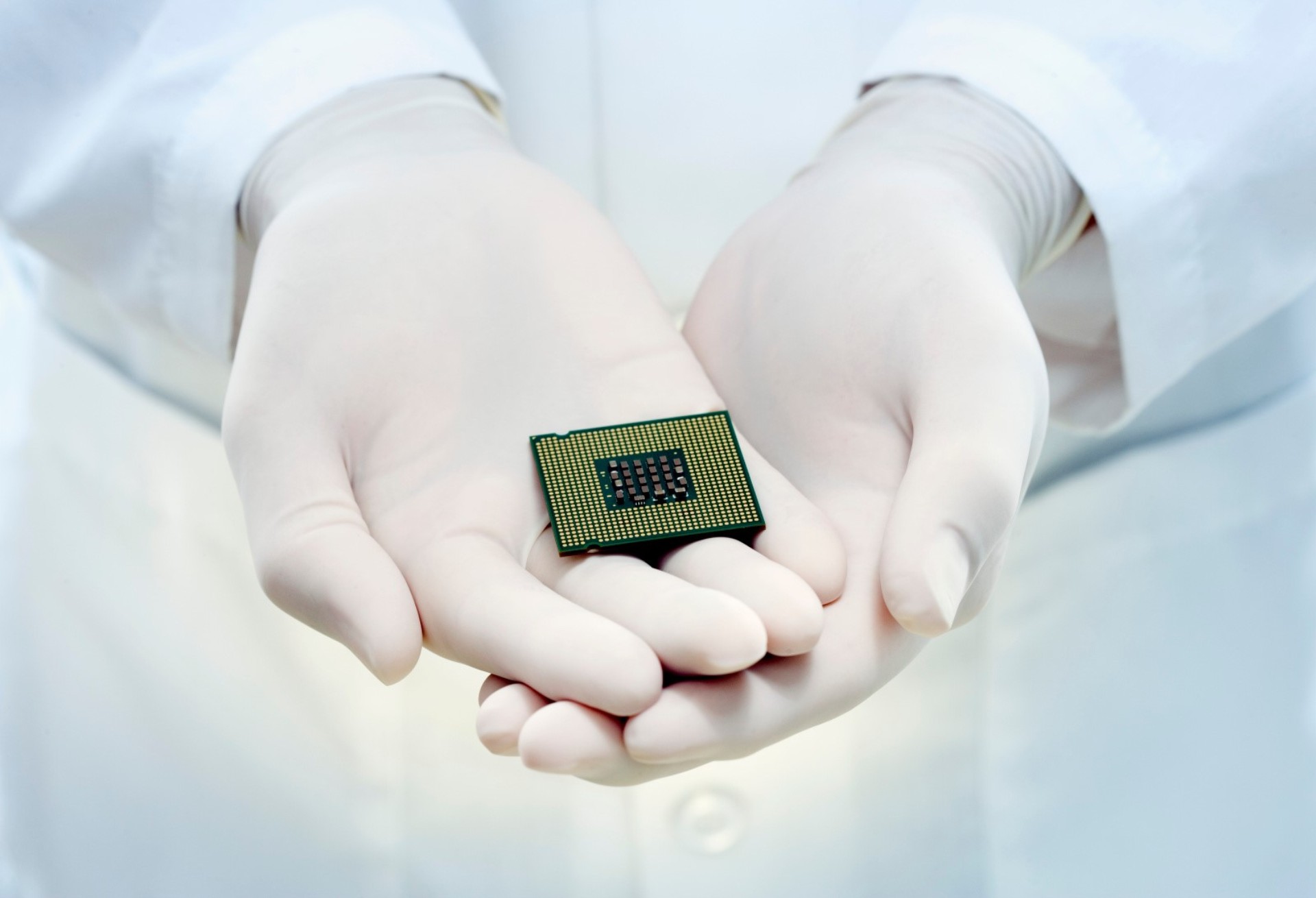

WACKER’s high-performance thermal interface materials offer excellent thermal conductivity, strong adhesion, and low modulus for stress absorption—ideal for flip-chip TIM1 applications. (Photo: WACKER)

“WACKER’s debut at CISCE is a valuable opportunity to introduce our latest products and technology solutions tailored for China’s industrial development,” said Alvin HU, President of WACKER China. “Our long-standing commitment to the Chinese market remains unwavering. CISCE offers an ideal platform to deepen collaboration with our Chinese partners and jointly drive industry innovation.”

At the expo, WACKER will feature more than 20 core products from its automotive materials portfolio, covering critical applications such as automotive chips and charging systems. Through an interactive virtual car model display, visitors will be able to see how WACKER’s high-performance silicone materials enhance the performance and reliability of essential vehicle components such as power battery and automotive interior.

“New-energy vehicles (NEVs) are a powerful driver of future development and a vital force in supporting China’s economic growth,” said Rick Wu, Vice President of Construction & Coating WACKER Silicones and Vice President of WACKER China. “As a global leader in silicone manufacturing, WACKER has long been dedicated to the automotive sector, continuously advancing silicone applications in NEVs to support the industry’s transformation. With a fully developed supply chain and vast market potential, China’s NEV industry is thriving. We look forward to close collaboration with our partners across the value chain, providing dependable, high-performance materials and solutions to help drive the sustainable and healthy growth of China’s NEV market.”

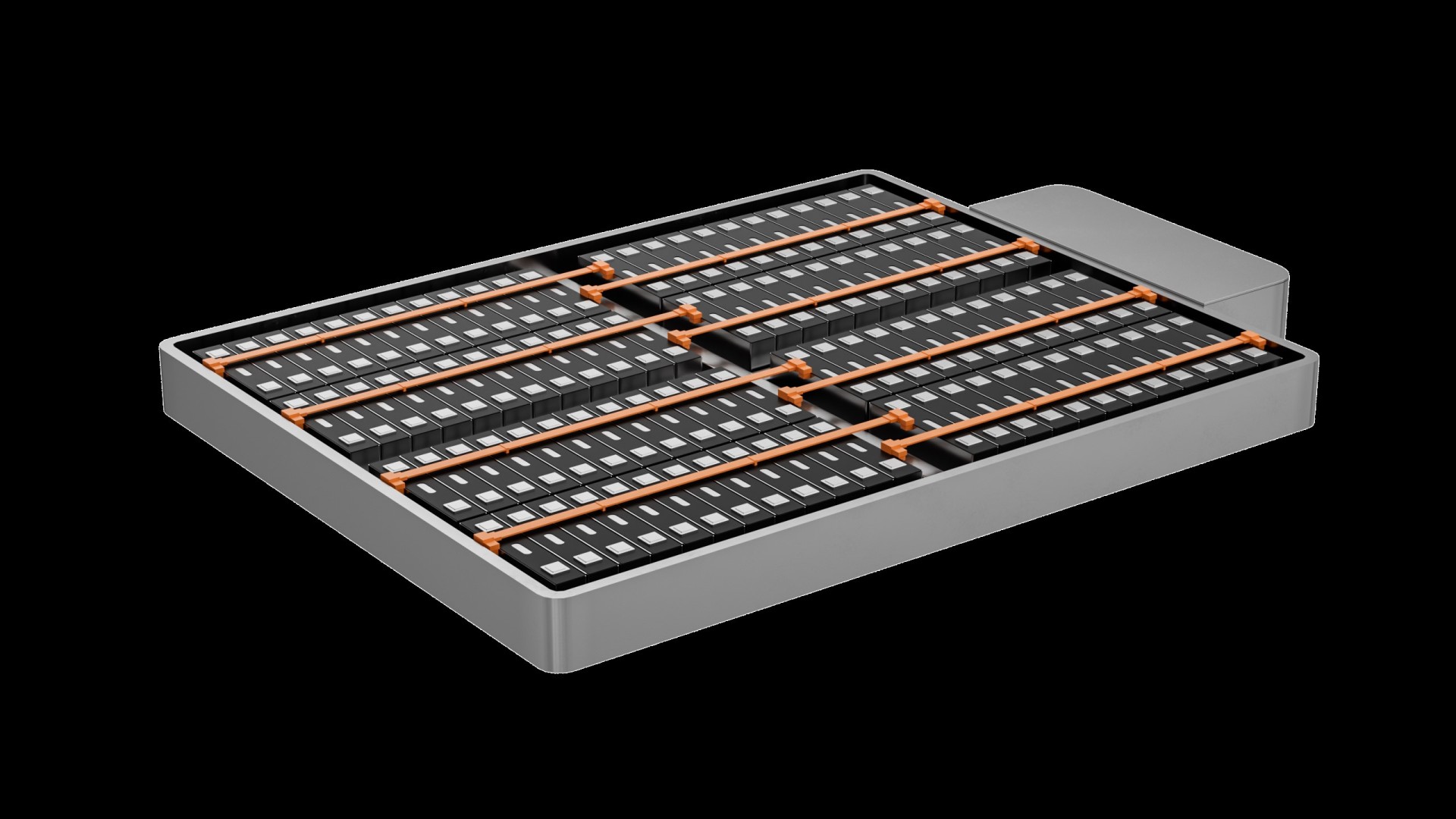

In the “Battery Safety” area, WACKER will showcase its newly developed flame-retardant, insulating silicone rubber — SILMIX® R CG 65871 ORG CN, designed specifically for the protection of battery busbars in NEV.

Busbars—essential for current distribution and conduction in a vehicle’s electric system—are critical to the overall efficiency and safety of the automobile. SILMIX® R CG 65871 ORG CN turns into a ceramic material rapidly when exposed to temperatures as high as 1000°C, preventing the spread of flames and maintaining insulation integrity. It can effectively provide safety protection even in the event of thermal runaway in the battery pack.

At CISCE, WACKER presents a flame-retardant silicone material for EV busbar insulation, featuring flexibility at low temperatures, stability at high temperatures, strong dielectric strength, and outstanding flame resistance—significantly enhancing busbar safety and reliability. (Photo: WACKER)

In the “Smart Driving” area, WACKER is also presenting advanced thermal management materials for automotive semiconductor packaging. As semiconductor devices and ECUs continue to miniaturize, their power components face rising thermal loads, requiring increasingly robust solutions to thermal management.

Among the featured products are SEMICOSIL® 993 TC and SEMICOSIL® 9910 TC, thermally conductive adhesives designed for TIM1 chip IC packaging applications. These materials perform highly reliable across a wide temperature range from -40°C to +180°C, maintaining consistent thermal conductivity even under prolonged high temperatures. They bond effectively to various materials e.g. metals and ceramics without a primer and cure at moderate temperatures, simplifying processing.

Another key highlight is SEMICOSIL® 96X9 TC, a high-performance thermally conductive grease for automotive-grade chip TIM2 applications. Featuring high thermal conductivity, low thermal resistance and excellent thermal stability, it is ideally suited for applications like LiDAR and autonomous driving systems.

WACKER is unveiling ELASTOSIL® R plus 4081/55 and ELASTOSIL® R plus 4381/80, two solid silicone materials designed for heat dissipation tubes and as sealant in NEV charging guns. Applied in the thermal management of NEV charging systems, these materials combine high thermal conductivity with excellent mechanical strength, addressing overheating issues in fast-charging systems and enhancing the durability of heat-conductive tubing.

In addition, WACKER is also showcasing a diverse lineup of products at CISCE, including optically clear resin (OCR), NEV silicone rubber cables, silicone leather, and silicone gaskets. These are used in various automotive applications such as interiors, waterproof door seals, and in-vehicle display systems.

At CISCE, WACKER will also unveil a range of silicone-based immersion cooling fluids, developed specifically to meet the thermal management demands of China’s high-performance computing (HPC) and data center markets. As AI and big data technologies continue to grow rapidly, traditional air cooling systems struggle to meet the increasing heat dissipation needs of modern servers and data centers.

WACKER’s immersion cooling fluids feature an innovative molecular structure that provides lower viscosity than conventional silicone coolants, enabling more efficient heat transfer. This contributes to lower Power Usage Effectiveness (PUE) and supports sustainable data center operations. With a high flash point of around 180°C, the fluid also enhances safety by reducing fire risk and preventing overheating-related incidents.

Dr. Liu Xuelin, Vice President of WACKER China, stated that WACKER’s products and technologies have found application across a wide range of emerging fields. WACKER looks forward to leveraging the CISCE platform to explore new application opportunities across China’s expansive industrial landscape and to collaborate closely with partners in driving sustainable growth across the industry.

Visit WACKER at Booth E2-B15, CISCE 2025.

Download

Documents

Press Information

view link