Dispersible Polymer Powders

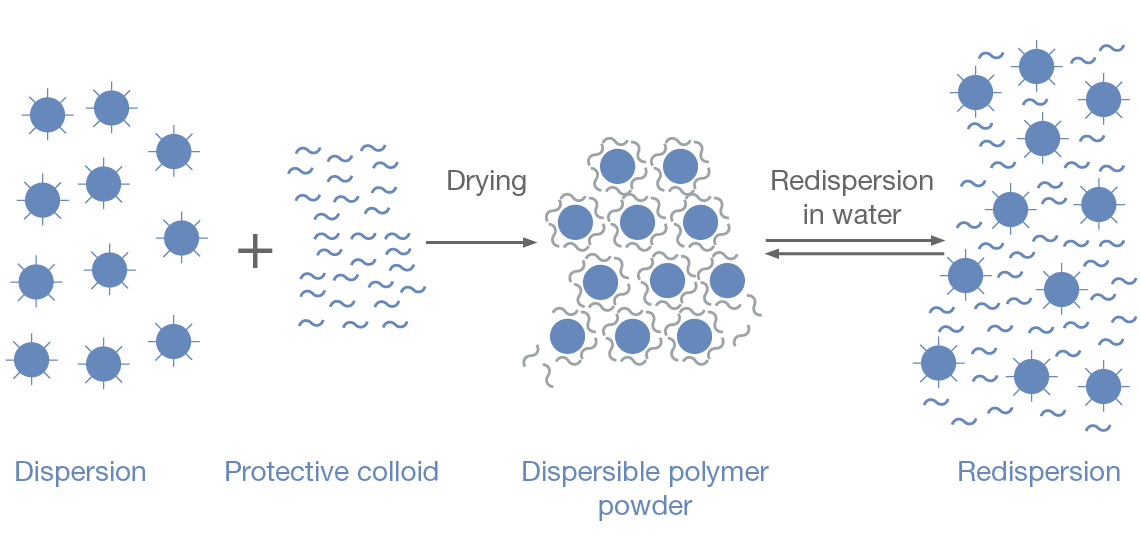

Polymer powders are produced by spray-drying polymer dispersions. In contact with water, the dispersible polymer powder grains disintegrate and release the individual dispersion particles again. The dispersed polymer powder has the same properties as the original dispersion. Polymer powders were first produced in WACKER laboratories in 1957. Today, WACKER is the world market-leader in polymer powders.

Dispersible Polymer Powder Production Process

Vinyl Acetate-Ethylene (VAE) Polymers

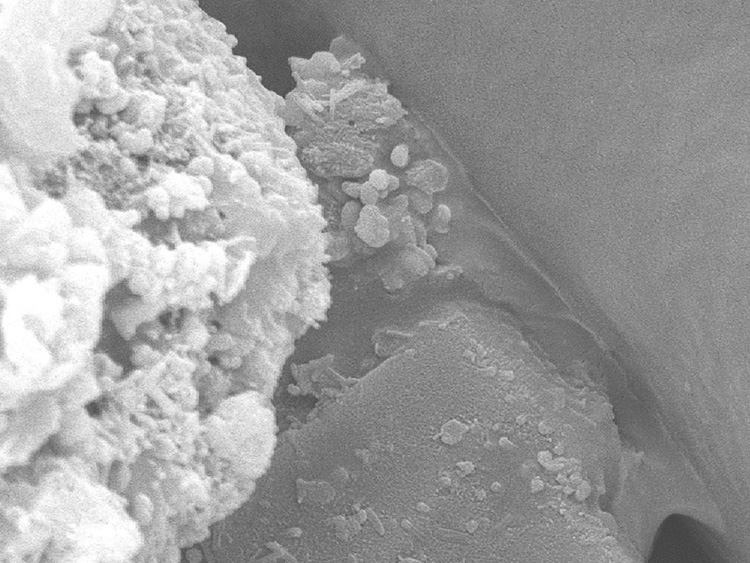

PVAc increases the adhesion of mortars. When the dry-mix mortar is mixed with water on the job-site, the polymer powder redisperses and forms polymer bridges as shown here.

Polymer powders based on VAE are marketed under the trade names VINNAPAS®, VINNACEL® and ETONIS®.

Main Characteristics:

VAE polymer powders combine the adhesion of vinyl acetate with the flexibility of ethylene. This leads to various ecological and economic benefits without compromising performance.

Main Benefits:

Main Application Areas:

Vinyl Chloride Co- and Terpolymers (VC)

Co- and terpolymer powders based on vinyl chloride are marketed under the tradename VINNAPAS®.

Main Characteristics:

VC-based dispersible polymer powders show excellent water resistance.

Main Benefits:

Main Application Areas:

Terpolymers Based on VAcE and VEOVA

Structure of VERSA® 12 – vinyl laurate by WACKER

Terpolymers based on VAcE and VEOVA are marketed under the trademark VINNAPAS®. VEOVA and vinyl laurate monomers are marketed under the name VERSA®.

Main Characteristics:

Polymer powders based on VAcE and VEOVA have a very low Tg.

Main Benefits:

Main Application Areas:

1k waterproofing membranes

Curious?

Discover our product range on the topic of dispersible polymer powders.