Waterproofing Membranes

With WACKER, different waterproofing systems can be formulated and optimized. VINNAPAS® polymer dispersions and dispersible polymer powders are ideal for the formulation of 1-component, ready-to-use, pasty waterproofing membranes as well as 1- and 2-component cementitious systems. GENIOSIL® WP silane-terminated polymers are key to liquid waterproofing membranes. VINNAPAS® polymer binders enhance the properties of bituminous-based liquid waterproofing systems.

1K Cementitious Waterproofing Membranes

Test Methods

VINNAPAS® dispersible polymer powders provide 1-component (1K) cementitious waterproofing membranes with adhesion and flexibility. The vinyl acetate-ethylene (VAE) grades comply with the requirements of European ecolabels such as Blue Angel, Emicode EC1 plus, etc.

Benefits:

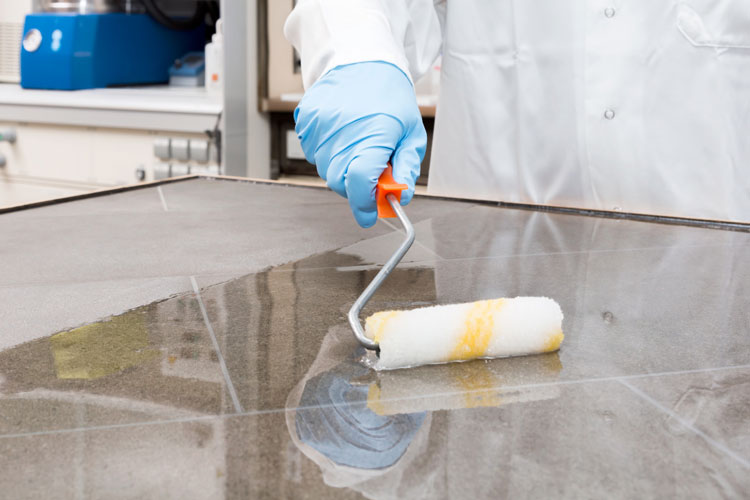

Formulation and Application Methods

Applications:

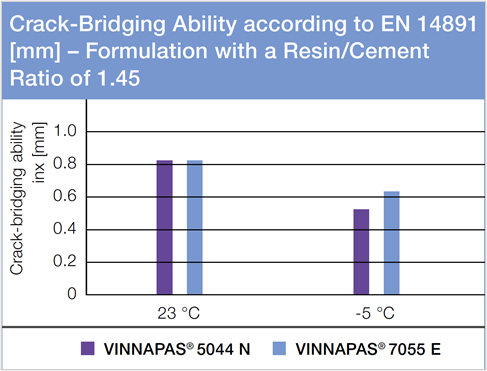

Good Crack-Bridging Ability

1-component (1K) waterproofing membranes modified with VINNAPAS® polymer powders can accommodate small movements in the substrate forming a reliable barrier against water leakage.

Brochures

VINNAPAS® | Dispersible Polymer Powders for Polymer-Modified Cementitious Waterproofing

Download2K Cementitious Waterproofing Membranes

Test Methods

VINNAPAS® vinyl-acetate ethylene (VAE) dispersions are used for 2-component (2K) cementitious waterproofing membranes because they greatly improve adhesion, cohesion and flexibility – even at low temperatures.

VINNAPAS® VAE grades can be easily mixed with other dispersions, as their solid content is high and their viscosity is low. They also provide good shear thinning properties and have practically no impact on the setting behavior of portland cement.

Benefits:

Formulation and Application Methods

Applications:

High adhesion bond strength

2K cementitious waterproofing membranes based on VINNAPAS® polymer dispersions easily pass requirements for water impermeability under hydrostatic water pressure (EN 14891).

High adhesion bond strength

2K cementitious waterproofing membranes based on VINNAPAS® polymer dispersions easily pass requirements for water impermeability under hydrostatic water pressure (EN 14891).

Brochures

VINNAPAS® | Dispersible Polymer Powders for Polymer-Modified Cementitious Waterproofing

Download1K Ready-to-Use Waterproofing Membranes

Test Methods

VINNAPAS® silanized styrene-acrylate (S/A) copolymer dispersions are ideal for ready-to-use, 1-component waterproofing membranes. Their special polymer composition makes them inherently hydrophobic, delivering maximum performance even under hydrostatic water pressure and displaying excellent crack-bridging ability.

Benefits:

Formulation and Application Methods

Applications:

Best Under Pressure

Tests show that ready-to-use, 1-component waterproofing membranes based on VINNAPAS® silanized S/A dispersions withstand hydrostatic water pressure of at least 1.5 bar for a minimum of 7 days.

Bitumen Waterproofing Membranes

VINNAPAS® polymer binders based on vinyl acetate-ethylene (VAE) copolymers and terpolymers are designed for the modification of bitumen emulsions. VINNAPAS® dispersions meet required European and ASTM standards and are suitable for one- (1K) and two-component (2K) systems, delivering exceptional adhesion and durability to bituminous waterproofing coatings.

Compared with conventional SBR and neoprene-based systems, VINNAPAS® polymers feature enhanced tear strength and crack-bridging properties, and can easily replace chlorine-containing polymers.

Benefits:

Applications

1K GENIOSIL® Low-Viscosity Hybrid Polymers for Liquid Waterproofing Systems

GENIOSIL® WP silane-terminated polymers are binders for 1K liquid waterproofing systems based on low-viscosity hybrid polymers with a unique property profile.

These highly stable, long-lasting systems can even be used under inclement conditions such as rain and cold (down to -10 °C) without incident. They dry very quickly and have properties comparable to those of polyurethane-based products – without the use of solvents or plasticizers.

And because the GENIOSIL® WP1 hybrid polymer is based on WACKER’s α-technology, it also eliminates the need for tin catalysts.

Benefits:

Application range:

1K GENIOSIL®Low-Viscosity Hybrid Polymers for High-Strength, Elastic Waterproofing Systems

GENIOSIL® XT silane-terminated polymers are binders for high-strength, elastic 1K waterproofing systems based on low-viscosity hybrid polymers.

Waterproofing systems like these produce little odor and can be applied with no personal protective equipment, even under inclement conditions. They dry very quickly and have properties comparable to those of polyurethane-based products – without the use of solvents or plasticizers. And selecting a product based on alpha-technology also eliminates the need for zinc catalysts.

Benefits: