Silanes and silicones for engineered stone

Silanes and silicones have clear advantages in the production of engineered stone.

Silanes form bridges between organic and inorganic components, which helps give engineered stones their outstanding properties.

The superior UV and heat resistance of silicone resins makes engineered stones suitable for use in new applications.

Silanes for engineered stone

GENIOSIL® silanes create a chemical bond between the organic and inorganic components of engineered stone, thus improving its mechanical properties.

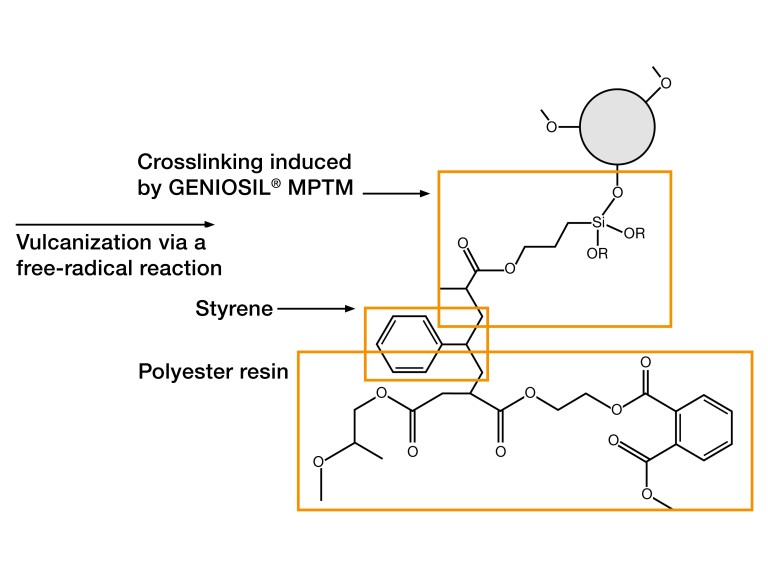

Engineered stone is a composite product based on minerals and unsaturated polyester resins. Silanes from WACKER's GENIOSIL® range produce a chemical bond between the organic resin and the inorganic mineral, while also greatly increasing mechanical strength. Just 1% GENIOSIL® relative to the binder is enough to transfer the strength of the hard, inorganic system to the soft, organic system.

Advantages

Application:

Silicone resin for engineered stone

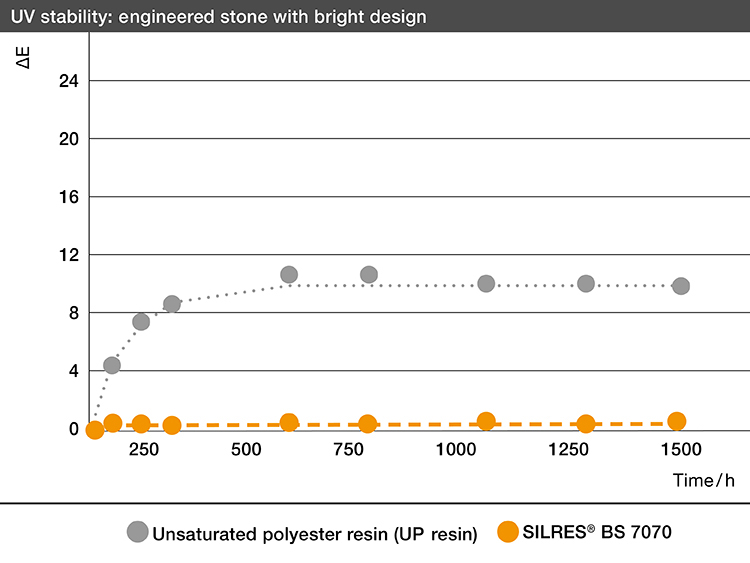

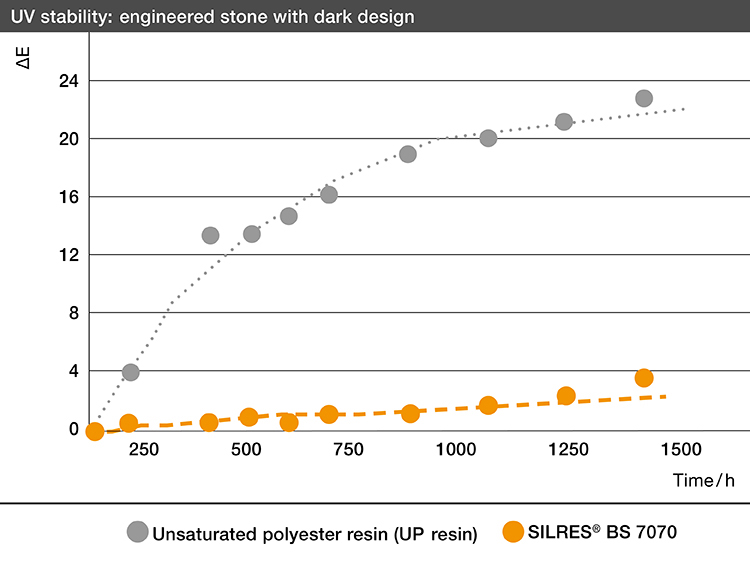

UV-resistant engineered stone for exterior applications? Silicone resin is what makes it possible. Replacing unsaturated polyester resins with a high-quality silicone resin binder makes engineered stone usable in exterior applications. Yellowing or fading as a result of direct sunlight is no longer an issue.

Advantages:

Applications:

The UV resistance of products based on SILRES® BS 7070 is outstanding.