WACKER Launches New Dispersion for Economical and Eco-Friendly Coatings with Mid-to-High Pigment Volume Concentrations

Shanghai, Nov 28, 2016

WACKER launches a new vinyl acetate-ethylene copolymer (VAE) dispersion developed specially for the Chinese interior coatings market. VINNAPAS® EP 618 provides excellent overall performance, in particular significantly improved scrub and chalking resistance. The low-odor dispersion further enables the formulation of paints and coatings with a low volatile-organic-compound content (VOC). As less binder is needed, VINNAPAS® EP 618 is ideal for the formulation of coatings with mid-to-high pigment volume concentrations (PVC) and a high cost-performance ratio.

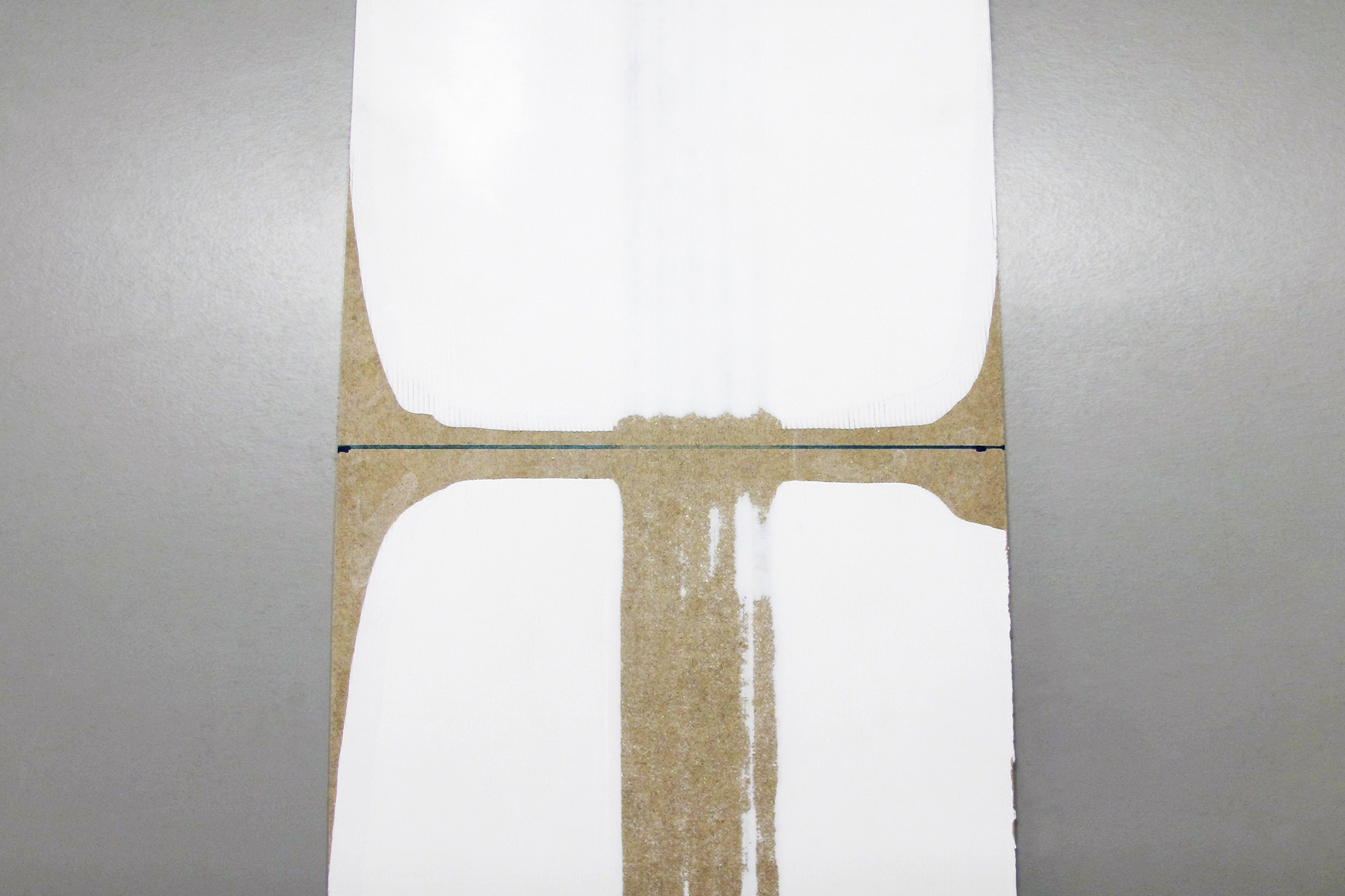

VINNAPAS® EP 618 combines the typical advantages of VAE technology, such as low VOC, low odor and outstanding film formation, with significantly improved mechanical properties, such as excellent scrub and chalking resistance. According to WACKER tests, in a 66% PVC coating recipe, VINNAPAS® EP 618 can reach 5000 scrub cycles, while in a 70% PVC coating recipe, it exhibits a better scrub resistance than standard VAE binders and a significantly better scrub resistance than standard vinyl-acrylate binders. Compared with standard styrene-acrylate binders, a similar performance level is achieved.

In mid-to-high PVC formulations, VINNAPAS® EP 618 shows broad formulation capability as well as high whitening/hiding power. Other notable advantages include outstanding over-paintability (touch-up properties) and good alkaline hydrolysis resistance. The excellent overall performance of VINNAPAS® EP 618 greatly enhances its cost performance ratio, and enables the formulation of coatings with mid-to-high PVC and low binder content.

Typically, vinyl and styrene acrylics with a higher glass transition temperature (Tg) need solvents or coalescing agents to lower the minimum film-forming temperature (MFFT) to values enabling proper film formation. Due to VAE technology, VINNAPAS® EP 618 has a lower MFFT than standard grades and thus needs less film-forming agent to achieve the required performance. In addition to lowering raw-material costs, this also leads to a reduction in VOC and odor levels compared with standard acrylic-based, higher Tg binders. VINNAPAS® EP 618 thus allows for low-VOC formulations that comply with such standards as HJ2537-2015 (VOC < 50 g/l) and JG/T481-2015 (VOC ≤ 20 g/l). Furthermore, the dispersion is produced without using alkylphenol ethoxylates (APEOs), which makes it an ideal choice for coatings manufacturers who pay special attention to environmental standards.

Contact

Wacker China

Media Relations & Information

Jessica He

Phone:+ 86 21 6130 2588

Email jessica.he@wacker.com

Send Message