Our system has noticed that you are based in , but the current country setting is . Select country

COMPAMED 2025

COMPAMED 2025, the world’s leading trade fair for cutting-edge medical technology, will take place in Düsseldorf from November 17 – 20.

Visit us in hall 8A at booth no. G04.

Next-level silicones. Designed for health care.

Whether you’re developing advanced wound care systems, transdermal drug delivery technologies, or high-performance MedTech equipment — we have something new for you.

Selection of applications for WACKER’s health care silicones:

New: Medical skin adhesive SILPURAN® eco 2114

At COMPAMED 2025, we will present SILPURAN® eco 2114. It is a medical silicone skin adhesive developed using a certified mass balance method. By incorporating bio methanol as the alternative raw material, the product delivers a demonstrably lower Product Carbon Footprint (PCF) compared to its conventional fossil-based equivalent.

This certified product is identical to its fossil counterpart in terms of specifications, quality and performance. Customers do not need to alter their formulations in any way.

With SILPURAN® eco 2114 customers replace its fossil counterpart SILPURAN® 2114 seamlessly.

New: Transdermal drug delivery from silicone gel adhesives

If transdermal delivery is a topic for you: Meet us! Our experts from the WACKER Health Care Competence Center in Ann Arbor, USA have conducted a product development study.

Transdermal patches are increasingly being used for non-prescription and cosmetic applications. WACKER therefore focused on developing silicone gels that can be used for administering the most common substances.

The goal was to achieve maximum and tailored release properties while maintaining the structural integrity of the adhesive coating. The active compound was embedded to a silicone gel matrix that is a maximum 300 micrometers thin.

More than 20 active ingredients have been tested:

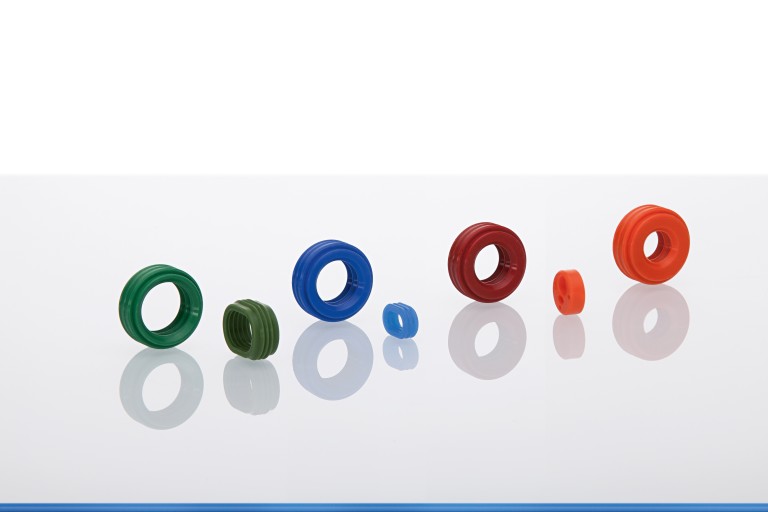

Self-Adhesive ELASTOSIL®

Thanks to patented self-adhesion technology, our liquid silicone rubber bonds reliably with polycarbonate, polysulfone and other high-performance thermoplastics without time-consuming pre-treatment. This is ideal for the cost-effective large-scale production of multicomponent medical-technology parts such as respiratory masks, drug delivery systems or devices for minimally invasive surgery.

ELASTOSIL® for medical technology

Applications range from seals, valves, septa, filters and membranes (such as those in syringe seals or membranes for needle-free injection systems), to respirators and respiratory bellows, handles for equipment and instruments or mats for sterilization trays.

Extrudable solid silicone rubber compounds are extremely tear resistant, highly elastic and remarkably resilient at the same time. They are used in numerous pharmaceutical and medical tubing applications, such as drainage, breathing and feeding tubes, urinary catheters and tubes for fluid transfer or in peristaltic pumps.

Questions about our presence at COMPAMED or our product portfolio?

Reserve your online ticket for COMPAMED 2025!

Register for COMPAMED 2025, November 17 – 20, 2025, and reserve your online ticket.

Q&A silicones for medical applications

2. How can I achieve longer wear time on the skin with soft silicone adhesives?

WACKER SILPURAN® skin adhesives may not achieve the same adhesive strength as aggressive acrylic adhesives, but wear times can be impressively long compared to commercially available “sensitive” acrylic systems, depending on individual conditions and the type of dressing. Wear time can be prolonged by selecting a strong silicone adhesive like SILPURAN® 2114 or SILPURAN® 2122.

3. Can wearables attached with silicone adhesives be cleaned and reused? How do I apply silicone adhesives to my device?

Yes, wearables attached with SILPURAN® silicone adhesives be cleaned and reused. For easy-to-handle products, we recommend separating the fixation element from the medical device in the product design. This makes it very easy to clean the product and replace the adhesive elements.

4. Are there High Consistency Rubber types especially suited for “Pharma Tubing“?

Our ELASTOSIL® R plus 4305 series is perfectly suited for the extrusion of tubes used in the production of pharmaceutical products. The addition curing material shows very good mechanical properties and is biocompatible. ELASTOSIL® R plus 4366 is the material of choice, where reduced friction is required to make the end application easier, e.g. where silicone slides over another surface. Therefore, it is especially suited for peristaltic pump hoses. Another grade targeted for the use in peristaltic pump hoses is ELASTOSIL® R plus 4360 with high rebound resilience and low compression set.

5. Why is ELASTOSIL® LR 3078 ideal for the 2K-production of medical multicomponent parts?

ELASTOSIL® LR 3078 enables considerable advantages when it comes to the large-scale production of multicomponent medical-technology parts: first, the material bonds reliably with polycarbonate, polysulfone and other high-performance thermoplastics in 2K production process. Second, our self-adhesive technology makes pretreatment unnecessary.

6. Is there self-adhesive liquid silicone rubber that reliably bonds with polycarbonate, polysulfone or other high-performance thermoplastics?

Yes, our ELASTOSIL® LR 3078 easily bonds with above mentioned high-performance thermoplastics, even without pretreatment. That’s a huge benefit, especially in cost-effective large-scale production of medical-technology parts such as respiratory masks, drug delivery systems or devices for minimally invasive surgery.

Related: