Gaskets

WACKER silicone rubbers possess excellent sealing and adhesive properties, are resistant to heat and fluids, and have excellent durability. This functional reliability helps to keep the occupants safe. Especially in the engine compartment, our silicone grades seal reliably under demanding conditions, such as high temperatures, constant vibration, and contact with fluids. Silicones are also an integral part of solid gaskets with their rugged multi-layer structure.

Fiber Gaskets

Solid gaskets face enormous challenges in combustion engines, where the sealing materials are pushed to their limits by high temperatures, high pressure, and extreme compressive loads. Fluid-resistant specialty grades from WACKER meet these challenges with aplomb. They ensure that the combustion chamber is safely insulated from the oil and coolant circuits, are easy to process by the usual methods and are suitable for all kinds of multi-layer solid gaskets.

Benefits:

- High heat stability

- Very good resistance to fluids

Applications:

- Cylinder-head gaskets

- Impregnation of substrate materials (whether or not they contain sulfur)

- Gasket contour can be screen printed

- Topcoats for surface sealing

Molded Seals

High-quality silicone rubber from WACKER enables you to produce all kinds of seals economically by injection molding. Seals are chiefly made with silicone whenever they are required to withstand high/low temperatures or aggressive chemicals without suffering damage. The comparatively low viscosity of WACKER liquid silicone rubbers allows very fine structures to be created in any color.

Benefits:

- Fuel, oil and chemical resistance

- Oil-bleeding

- Flame resistant

- Heat resistance over a wide temperature range (from -90 °C to +300 °C).

Applications:

- Molded Seals

- Engine gaskets

- Oil-pan seals

- Coolant-system seals

- Sealing mats used in multipin plugs and for single-wire and radial seals

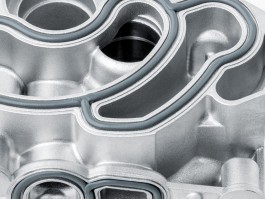

Cured-In-Place Gaskets (Dry Assembly)

CIPG (also known as “dry assembly”) is a sealing technique in which a bead of non-slump silicone is first applied to one of the parts to be sealed. The bead is then allowed to cure and the parts are assembled. The seal is created via the compressive load. CIPG sealing technology therefore requires silicone grades that will not deform when subjected to high compression for an extended period of time and have a particularly low compression set.

Benefits:

- Highly versatile processing

- Simple processing

- High cost-efficiency

- Nondestructive disassembly possible

- Integrated gasket

Applications:

- Radiator gaskets

- Sealing of water pumps and oil pumps

- Housing seals

- Sound and heat insulation

- Shock and vibration decoupling

Formed-In-Place Gaskets (Wet Assembly)

In the FIPG technique (also known as “wet assembly”), the parts to be sealed are assembled before the silicone rubber cures. The gasket material therefore adheres to both surfaces after curing. This makes the seal more reliable, but rules out any possibility of subsequent disassembly.

Unlike inserted gaskets, FIPGs do not require the mating surfaces to have high dimensional accuracy. In addition, the cured gasket material remains securely in place without the need for additional fixing. These two aspects allow wider part tolerances and lower the cost of parts development.

Benefits:

- Effective bonding

- Highly stable joint

- Uniform stress distribution and perfect stress relaxation

- Versatility

- High cost-efficiency

Applications:

- Oil-pan gaskets

- Gearbox seals

- Headlamp bonding

- Sealing housings against moisture and the effects of weathering