A Building’s Sustainability Already Begins When Choosing Construction Materials.

May 26, 2020 Read time: approx. MinutesMinute

Certified Alternative

More and more architects and property developers are incorporating ecological aspects into their design specifications – such as the source of the building materials to be used. In VINNAPAS® eco dispersible polymer powders (formerly VINNECO®), WACKER is now offering polymers that are based on acetic acid derived from scrap timber.

Last year, the consulting firm A.T. Kearney asked a 1,500-strong representative sample of the German population to identify the measures they thought would be most effective at reducing the average citizen’s CO2 emissions. They were given seven options to choose from. Just four percent selected the right answer: building insulation.

Modern external thermal insulation composite systems (ETICS/EIFS) consist of a base coat, an insulating material such as expanded polystyrene or mineral wool, and a finishing plaster. These systems are ideal for retrofitting buildings and slashing their energy consumption. A secure permanent bond between the insulation panel and an existing building envelope can be achieved with a WACKER VAE (e.g. vinyl acetate-ethylene copolymer) dispersible polymer powder content of less than four percent.

Attaching an exterior insulation and finish system to a facade. The adhesive mortar to which the actual insulation is fitted needs vinyl acetate-ethylene dispersions if it is to produce the necessary adhesive strength.

Because of their high bonding strength and great flexibility, VINNAPAS® VAE dispersible polymer powders from WACKER are the leading brand in many building applications. They are just as likely to be found in adhesive mortars for insulation panels as they are in wall paints and dry-mix mortars used as binders in tile adhesives, self-leveling flooring compounds and plastering mortars. Until recently, the constituent raw materials – ethylene and the acetic acid precursor needed for producing the vinyl acetate – would have been obtained exclusively from natural gas and crude oil, i.e. fossil sources.

A number of European countries have, however, already issued environmental declarations on construction materials that are influencing architects’ choices of materials during the planning stage. This is a trend that the European Union and national legislators are likely to try and reinforce over the next few years. End consumers, including many a DIY enthusiast, are also becoming increasingly fussy about where the raw materials in their tile adhesives and interior paints come from.

The timber on which the VINNAPAS® eco product line is based comes from certified woodland located no further than 500 kilometers away from the Burghausen production site.

Construction-Sector Market Research

A 2019 market research poll commissioned by WACKER shows that European manufacturers of building materials are responding to this market need. The researchers asked procurement and research departments at construction-sector companies to name the areas where they would like to advance innovations in collaboration with WACKER. Some 41 percent of respondents cited sustainability.

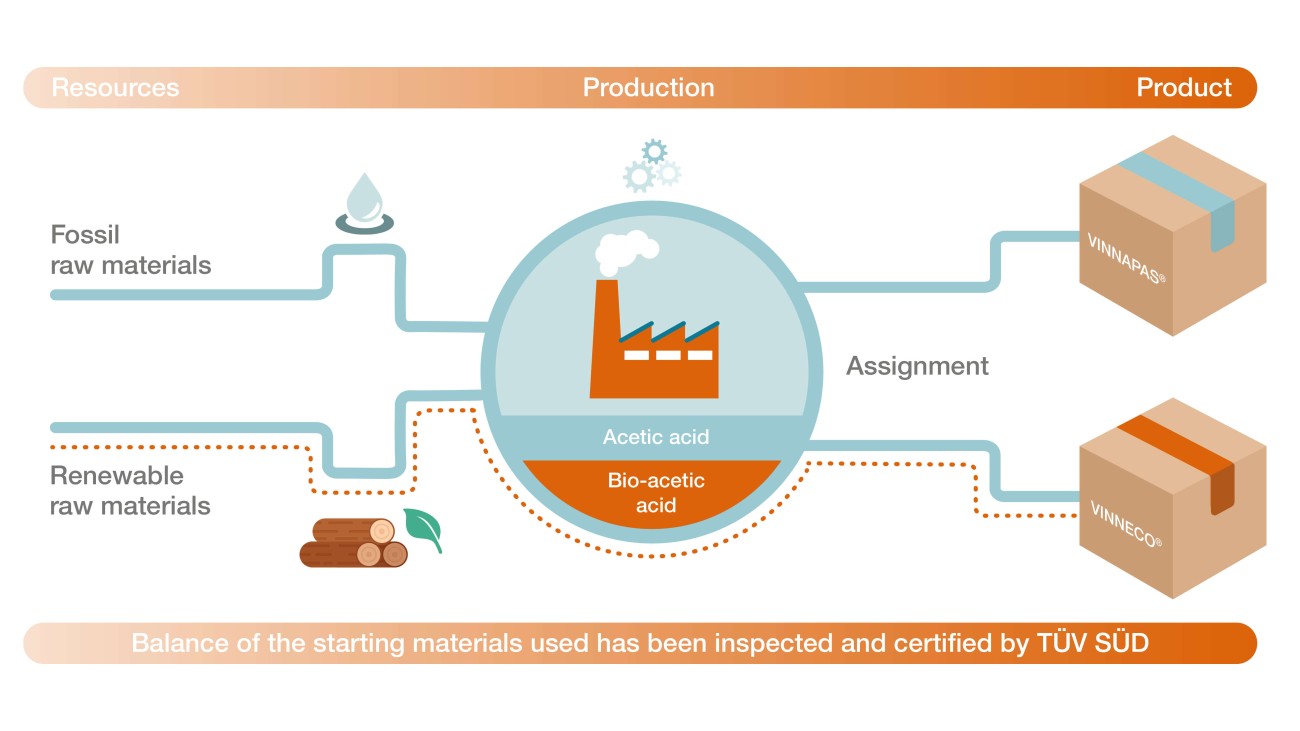

Accordingly, WACKER is now pursuing a new path as regards VAE dispersible polymer powders. Its customers are now being offered an alternative to VINNAPAS® 5044 N, one of its most popular sales products. Mathematically, this alternative is made entirely from renewable raw materials. What this means is that bio-acetic acid will be used in such quantities in the production of the VAE dispersible polymer powders that, in the mass balance, it will be accounted for as offsetting the fossil-based constituents, which will continue to be used in the production of VINNAPAS® eco 5044 N, the “green” alternative.

Bio-based acetic acid is a byproduct of woodworking industries such as the cellulose industry. The wood itself is sourced from sustainably managed forests within a 500-kilometer radius of WACKER’s Burghausen site, and the resulting bio-based acetic acid has been certified according to the PEFC® (Programme for the Endorsement of Forest Certification) standard. In addition to keeping CO2 emissions low, this also minimizes transportation and logistics outlay.

“Mass balance accounting has nothing to do with ‘greenwashing’ or simply sticking a ‘green’ label on products.”

– Frank Reichle, Director of Construction Polymers Western Europe

“Every customer who buys VINNECO® 5044 N (today VINNAPAS® eco 5044 N) will help to increase the content of renewable raw materials in the dispersible polymer powders produced at WACKER,” says Frank Reichle. Mass balance accounting is a way of calculating the proportion of VAE dispersions produced from renewable and thus non-fossil raw materials.

And verifiably so, stresses Reichle’s colleague, sales manager Claudia Mauritz: “The internationally recognized testing and certification body TÜV Süd has certified that our mass balance accounting method meets the criteria of the global CMS 71 standard.”

Everything In a Single Plant

The two grades, VINNAPAS® 5044 N and VINNAPAS® eco 5044 N, are produced on the same line in Burghausen. Separate production with fossil raw materials on one hand and renewable resources on the other would not be economically viable at the moment. “However, that might change over the long term, especially if there is strong enough demand for VINNECO® (today VINNAPAS® eco) from our customers,” notes Reichle.

By the way, customers who have hitherto been using VINNAPAS® 5044 N do not have to make any changes to recipes or processes when switching over to the bio-based grade VINNAPAS® eco 5044 N. The two dispersible polymer powders are chemically identical and possess the same properties.

However, anyone buying VINNAPAS® eco has the certainty of making a certified contribution to reducing the ecological footprint of dispersible polymer powders production at WACKER. And because marketing is about not just doing something good, but also talking about it, manufacturers of construction materials may also use the TÜV Süd certificate for their own certification. “This means that they in turn can tell their customers that the VAE polymers in their products come from renewable raw materials,” Mauritz explains.

The VINNECO® brand (today VINNAPAS® eco), which stands for products based on renewable raw materials, was launched for (liquid) dispersions over a year ago. In launching VINNAPAS® eco 5044 N, WACKER is now pioneering biobased grades of dispersible polymer powders. “As a top-seller, VINNECO® 5044 N (today VINNAPAS® eco 5044 N) is ideal for external thermal insulation composite systems, its main application,” she adds. “But if our customers so wish, in addition to 5044 N, we can, with a few months’ lead time, offer further VINNECO® (today VINNAPAS® eco) grades based on acetic acid sourced from renewable resources.”

One plant for two feedstocks: One and the same plant manufactures not only VINNAPAS® and VINNAPAS® eco, but also BELSIL® and BELSIL® eco products. The mass balance method is used to calculate mathematically the amount

based on renewable raw materials. Chemically speaking, both products are absolutely identical.