Orthotics & Prosthetics

WACKER RTV-2 Systems Make All the Difference

ELASTOSIL® P and SILPURAN® room-temperature-vulcanizing (RTV) silicone elastomers and gels are specially designed to meet specific prosthetic and orthotic demands. Orthotics focus on properties such the ability to cushion shock and vibration, and to apply gentle, comfortable compression. Prosthetics is a highly sensitive area of application. The aim is to make prostheses and epitheses that fit perfectly, are comfortable to wear, and are barely noticeable.

ELASTOSIL® P and SILPURAN®’s exceptional set of properties allow customized production of:

Benefits of ELASTOSIL® P and SILPURAN® silicone elastomers:

Do I have to invest a lot to manufacture orthotic and prosthetic parts?

No, due to the 1:1 mixing ratio, low viscosity and long pot life at room temperature, silicone elastomers in the ELASTOSIL® P series can easily be manually dosed, mixed and molded. Production time can be reduced by curing at high temperatures, for example at 120°C. There are cost-effective mixing and metering systems for processing ELASTOSIL® P upward of specific production volumes. Please contact us for details of suitable equipment suppliers.

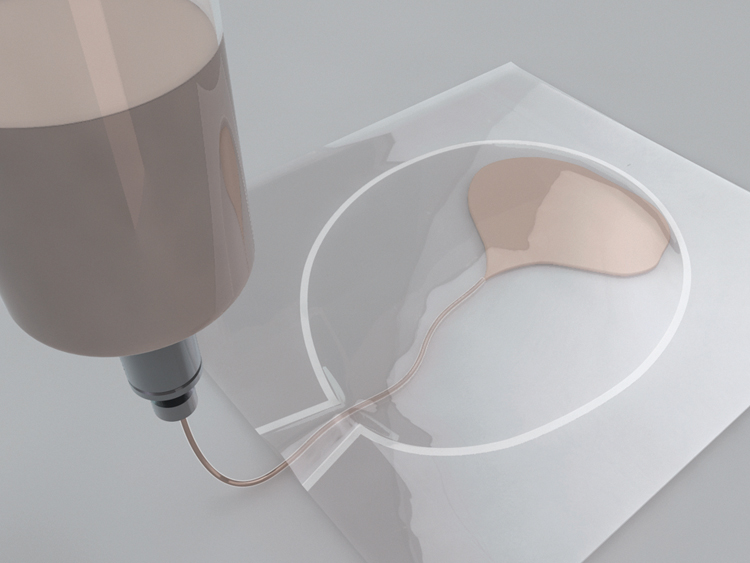

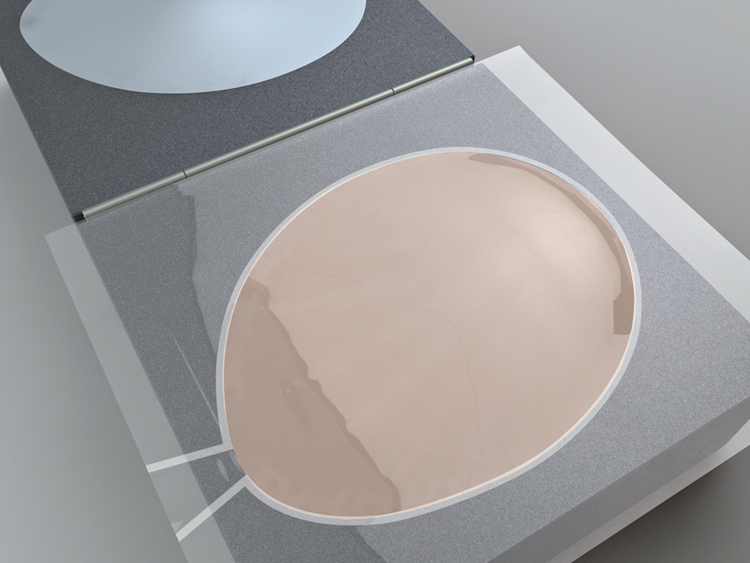

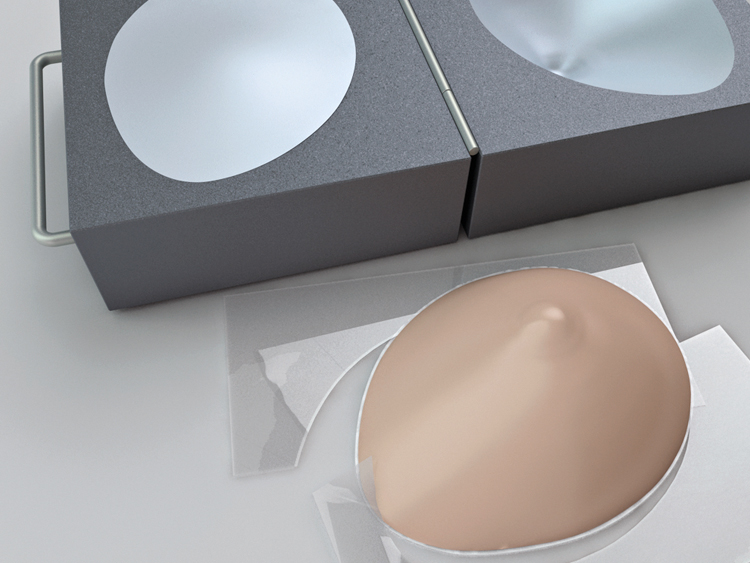

Are there any lightweight filling materials for external mammary prostheses?

Thanks to its low density, lightweight ELASTOSIL® P 7630 gel can reduce the weight of the prosthesis by more than a third compared to conventional silicone gels.

Do the gel materials used in prostheses adhere well to polyurethane film in order to avoid the separation of outer skin and filling material?

Yes, ELASTOSIL® P gels adhere well to polyurethane film.

Are there any silicone elastomers that can be used to produce prosthetic liners?

The ELASTOSIL® P 768x series is ideal for casting prosthetic liners with good durability and excellent mechanical properties. You can choose from a broad range of hardness levels from soft (sh00 25) through medium to hard (shA 12 / sh00 60). Low viscosity enables a fast and simple casting process with the end product exhibiting excellent mechanical properties.

Can I achieve good damping properties with silicone rubber compounds for pelottes, pads and insoles?

ELASTOSIL® P 7600 and the P 767x series contain silicone rubber compounds with excellent damping properties to reduce and cushion shocks and vibrations. Several grades of hardness are available and all the products are easy to process due to their low viscosity.