Innovative silicone resin binders make it possible to use injection molding to manufacture mechanically and thermally stable molded plastic parts

Read time: approx. MinutesMinute

Heat-Resistant up to 220 Degrees Celsius

Innovative silicone resin binders from WACKER open up the door to mechanically and thermally stable molded plastic parts manufactured using injection molding – truly uncharted waters for the company.

You can hear a touch of pride in the voice of Dr. Jens Lambrecht from WACKER Technical Service: “Our new material solution is taking us into truly uncharted waters,” the electrical engineer says. It is true, of course, that not only industrial manufacturers, but also self-employed builders and decorators already use silicone resins to make molded parts that are stable and mechanically robust even at extremely high temperatures, while also exhibiting electrically insulating properties. Sophisticated molded parts like these are needed in electrically insulating technology for future innovative applications currently under development – in order to protect hub motors in electric vehicles, for instance.

Up to now, processors would first produce semi-finished parts by laminating starting products with silicone resin binders and would then finish them later to create the final shape. “Preparing laminates from a silicone resin and glass or carbon fiber, pressing them and then processing them mechanically – that’s quite a labor-intensive process and it produces a lot of scrap, a lot of waste,” as Lambert knows.

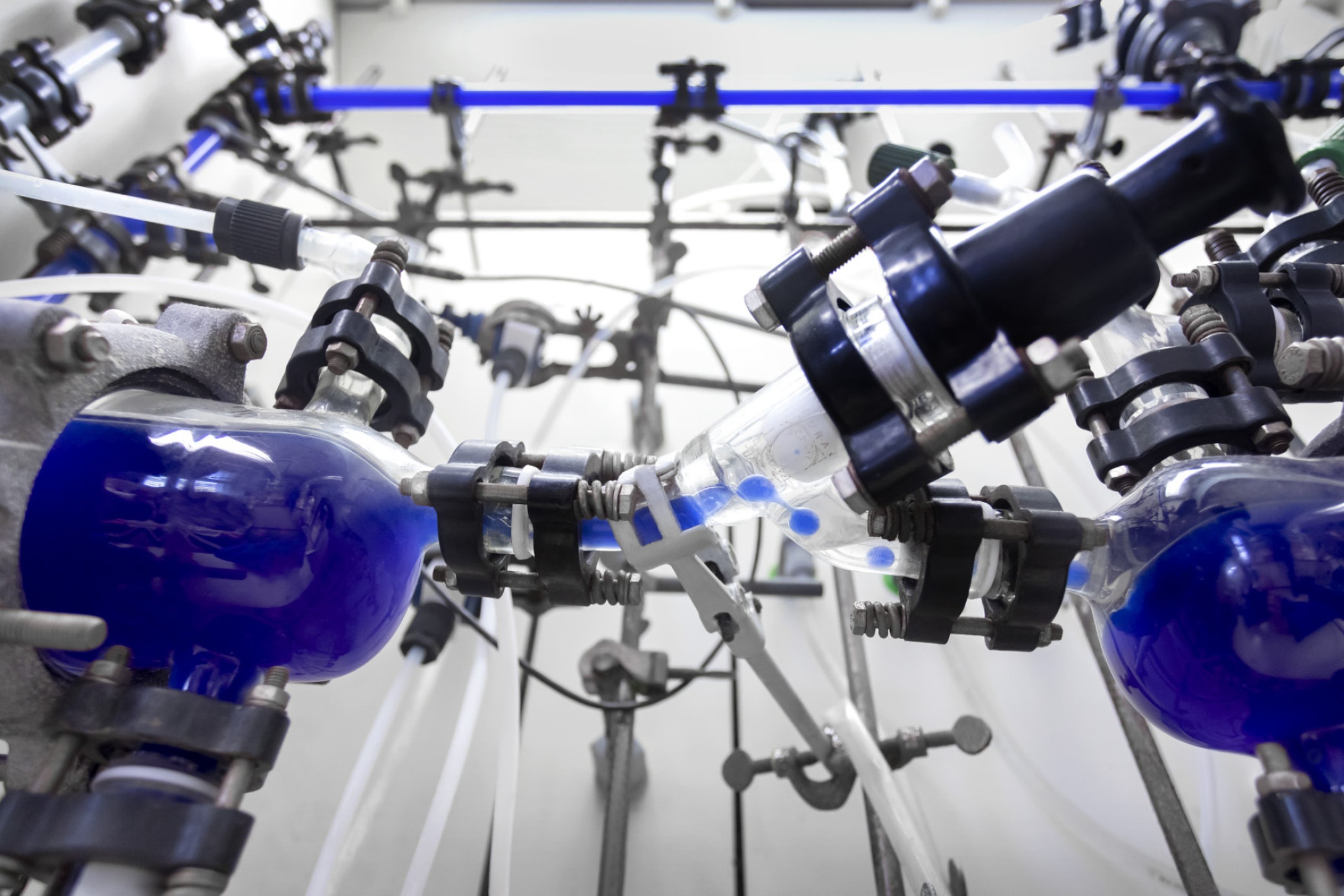

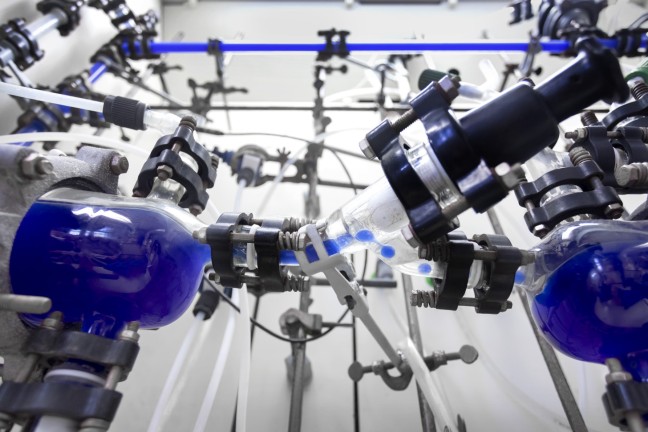

Glass circulating reactor: WACKER has developed a continuous manufacturing process for resin binders at a technical service lab at its Burghausen production site.

“The previous process produced a lot of scrap, a lot of waste.”

Dr. Jens Lambrecht, electrical engineer, WACKER Technical Service

Up to now, direct, less complex processes such as injection molding have failed, both for lack of suitable binders and because the mechanical properties of the cured silicone resin compound are unsatisfactory. And competing materials in a similar heat-resistance class – such as PTFE (polytetrafluoroethylene), otherwise known as Teflon™, and PEEK (polyether ether ketone) – either make processing complicated or lack the thermoset properties needed.

SILRES® LR 700 and POWERSIL® Resin 700 now put efficient, cost-effective processing within reach, even for molded parts that remain stable at high temperatures. “Introducing these two silicone resins will put materials on the market that are as easy to process as, say, polyurethane or epoxy resins – plastics that are very commonly used in the production of components subject to much lower thermal stresses,” Lambrecht points out.

Dr. Frank Sandmeyer, a WACKER chemist responsible for developing the underlying silicone resin, discovered an ingenious way of incorporating phenyl groups into the polysiloxane backbone, thus making the cured silicone components significantly less brittle. “What we needed was an easy-to-handle liquid silicone resin that would be both exceptionally heat resistant as well as relatively reactive,” says Sandmeyer, recalling the specifications he was given during the development phase.

Appropriate fillers provide considerable mechanical strength. Dr. Lambrecht worked with technology manager Dr. Markus Winterer on numerous series of experiments with pyrogenic silica, quartz and glass fibers to develop an initial optimized filler blend. The liquid silicone resin, this filler blend and a peroxide as crosslinker are the ingredients that make up compounded POWERSIL® Resin 710 – a product for customers who would prefer a ready-to-use material solution.

The new silicone resin technology is an advantageous alternative to high-temperature-resistant polymers like PTFE and PEEK. Injection molding cannot be applied with PTFE, for instance, which has to be compressed or sintered at temperatures of over 360 °C. Temperatures are similarly high for PEEK injection molding. The silicone resin in POWERSIL® Resin 710, by contrast, crosslinks at only about 160 °C.

“This innovation is our answer to rising industry demand for polymers that resist high temperatures,” Lambrecht explains. Because technical systems are growing increasingly powerful even as they become smaller, they now release more heat per unit volume. Again, motors in electric vehicles are a good example of this trend. Electrically insulating polymer components located in or near sources of heat like these need to work perfectly for many years, retaining their properties at the resulting

high temperatures.

“We’ve incorporated a phenyl group into the polysiloxane backbone of the silicone resin, which makes the cured silicone components significantly less brittle.”

Dr. Frank Sandmeyer, chemist specializing in WACKER silicone resins

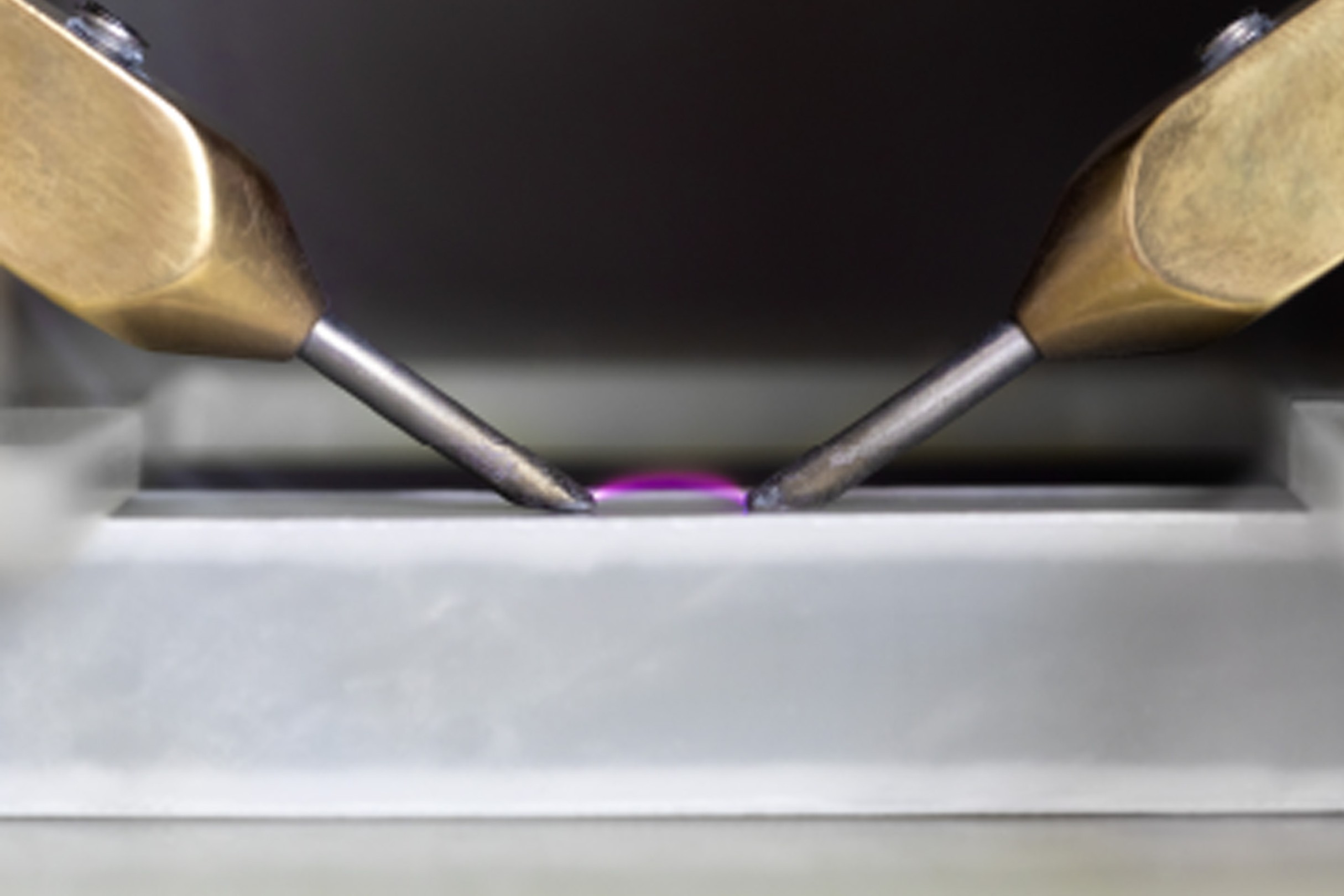

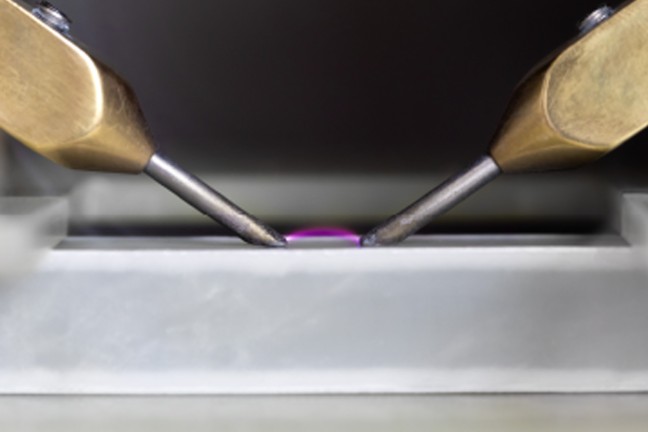

Making a good impression, even at high temperatures: plastic molded parts made from WACKER’s new silicone resin undergoing IEC 61621 testing.

Tests Demonstrate Thermal Resistance of the Silicone Resin

Samples of molded parts made from POWERSIL® Resin 710 were stored at a variety of temperatures in order to determine their thermal resistance. WACKER technicians then measured the percentage change in the binder

mass over time as a function of storage temperature. Using a standardized mathematical method, they then extrapolated the insulation

class as a measure of the long-term service temperature. The result of this accelerated thermal aging process is that the molded parts made from these silicone resins met the criteria for insulation class R, which means they will withstand temperatures of up to 220 °C.

WACKER also tested the behavior of POWERSIL® Resin 710 samples that underwent frequent deformation. Each of these samples – strips eight centimeters long, one centimeter wide and four millimeters thick – were affixed only by their ends. The mandrel of a test instrument then repeatedly pressed down on the middle of the strips with a defined force. The result: the material withstood several hundred cycles of severe deformation and tens of thousands of cycles of modest deformation.

The new binders contain reactive double bonds that form crosslinking ethylene bridges

in the presence of a catalyst. Some customers may want to use the new liquid silicone resin binders to establish their own in-house technology for making molded parts. Alongside peroxide curing, these users may also wish to consider what is known as an addition-curing process, which is typically used for liquid silicone rubber.

“This innovation is our answer to rising demand for polymers that resist high temperatures.”

Dr. Jens Lambrecht, electrical engineer, WACKER Technical Service

As Lambrecht notes, “That kind of processing technology offers two advantages,” which the WACKER developer then goes on to name: “It can be applied at relatively low temperatures, and the curing speed of the resin can be adjusted by varying the temperature.”

As is always the case with product developments like this, chemists and engineers begin with batch production on a laboratory scale in order to create initial samples for internal tests and for potential customers. Given the highly positive feedback, both internal and external, that the developers received for the outstanding property profiles of the two silicone resin binders, the challenge now was to develop a continuous production process as quickly as possible.

At WACKER SILICONES, this job, i.e. scaling up the process, is the responsibility of Technology Management, and in this particular case the challenge is being taken on by the Alkoxy/P-Resins Laboratory managed by Dr. Georg Lössel. The focus of this development stage is now on a continuous process – both for phase separation and product washing – that will enable efficient production. Measured in kilograms produced per hour, mass throughput of a continuous process is far greater – by a factor of five to ten – than that of batch production, which means that future customers likewise stand to benefit from this kind of neatly scaled-up process. “What we’ve done is create a foundation that will allow us to scale up the current process for manufacturing these silicone resins in three stages – from the lab through to our WACKER SILICONES pilot plant and the industrial-scale process,” says Lössel.