Biopolymers That Stand Up to Everyday Demands

The future belongs to bioplastics – a term referring to biopolymers that are either manufactured from renewable raw materials or that are biodegradable. When it comes to their mechanical properties, however, these two groups often cannot compete with conventional plastics. A new additive blend from WACKER for biodegradable polymers aims to change that.

VINNEX® and GENIOPLAST® – a Winning Combination

Addition of VINNEX®, a performance additive based on poly(vinyl acetate), along with silicone-based GENIOPLAST® substantially improves the mechanical characteristics of thermoplastic bioplastics – from better flow properties to a versatile end product.

Two Additives – One Powerful Combination

Increased scrub resistance makes surfaces smooth and free of scratches

Better mechanical properties, such as improved tensile strength and flexibility

No negative impact on adhesion and improved heat-sealing performance on a wide range of surfaces

No impact on transparency – packaging and films remain as transparent as desired

Thermoplastic molding compounds are easier to produce and process – enhanced compatibility, reduced torque and better melt flow properties

Putting Two Bioplastics to the Test

In the following test series, we studied two materials as examples of how bioplastics behave in combination with VINNEX ® and GENIOPLAST® additives:

- Poly(lactic acid) or PLA, a bioplastic consisting of polymerized lactic acid, is made from corn starch and biodegrades in industrial composting processes. Because it is highly transparent and strong, it is popular for use in packaging.

- Poly(butylene succinate) or PBS is a fossil-based bioplastic that is likewise biodegradable. Typical applications include packaging, plastic mulch and medical products.

We would be happy to test additional bioplastic combinations for you.

Test Result 1:

Efficient Processing

The use of VINNEX ® and GENIOPLAST® blends makes thermoplastic bioplastics noticeably easier to process. Their addition prevents extrusion die drool, enables reduced nozzle pressure and decreases torque, for example.

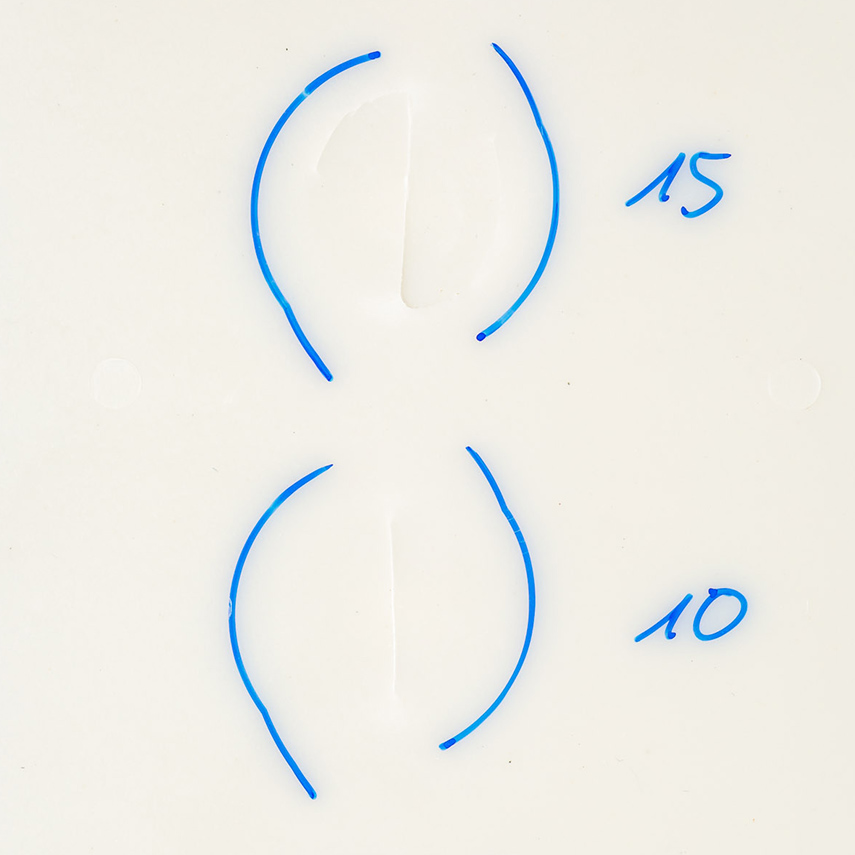

Injection molded plaques:

PLA IngeoTM Biopolymer 4043 (unfilled) and BioPBSTM FZ91PM +15% CaCO3 (filled)

When VINNEX® is incorporated at a concentration of 10 to 15%, a 1% dosage of GENIOPLAST® Pellets is enough to significantly reduce the coefficient of friction (middle and final bars).

PLA IngeoTM 4043, unfilled

BioPBSTM FZ91PM +15% CaCo3, filled

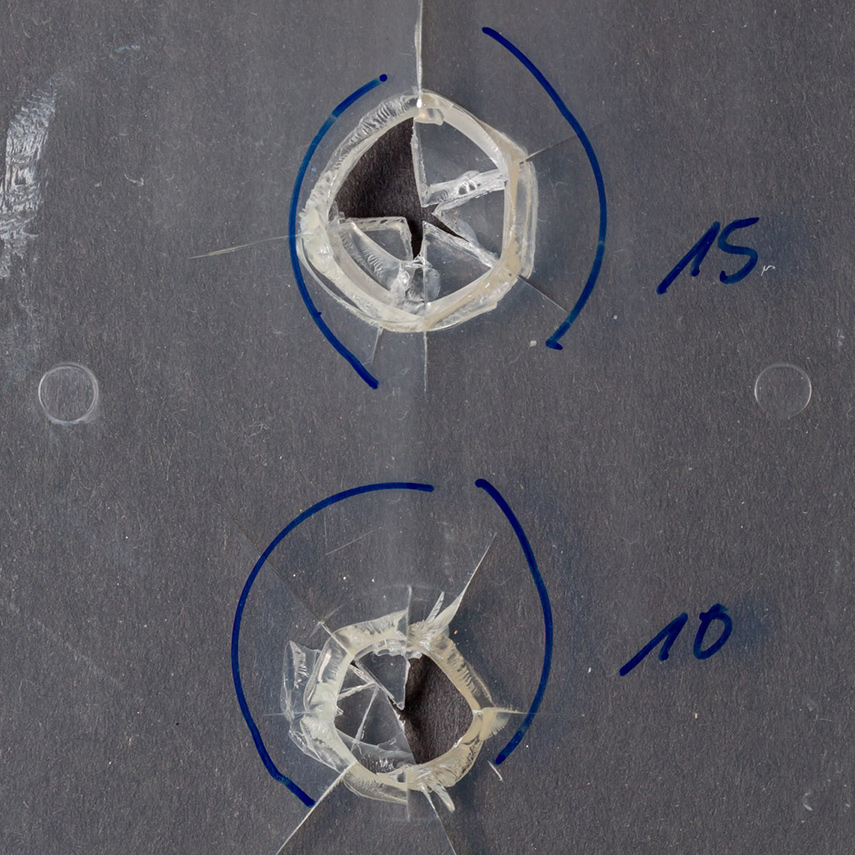

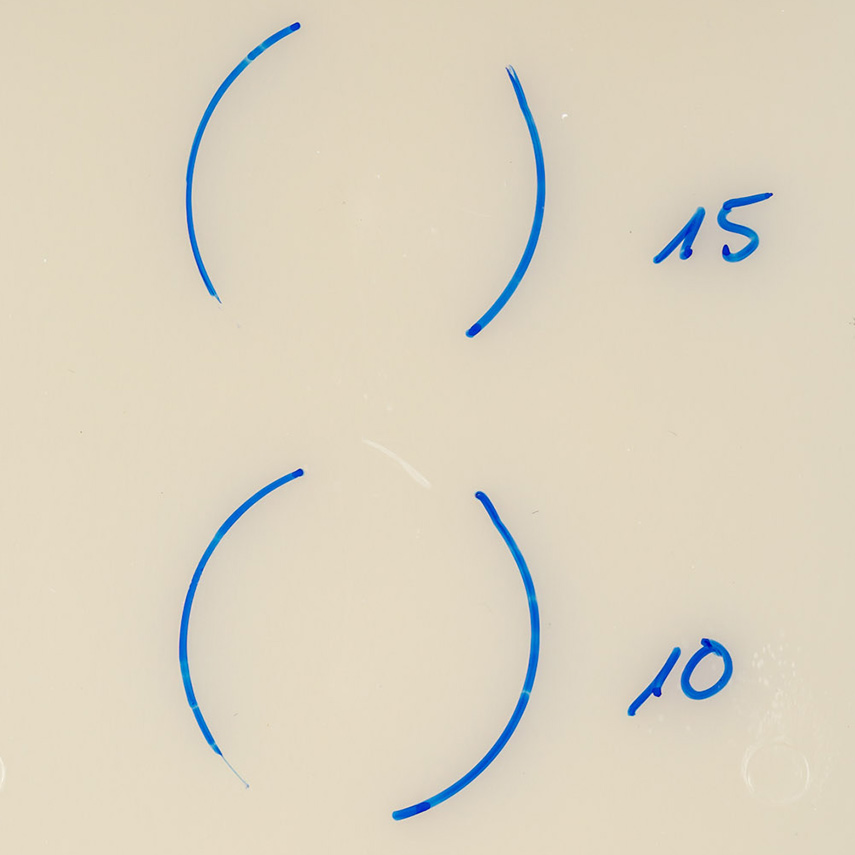

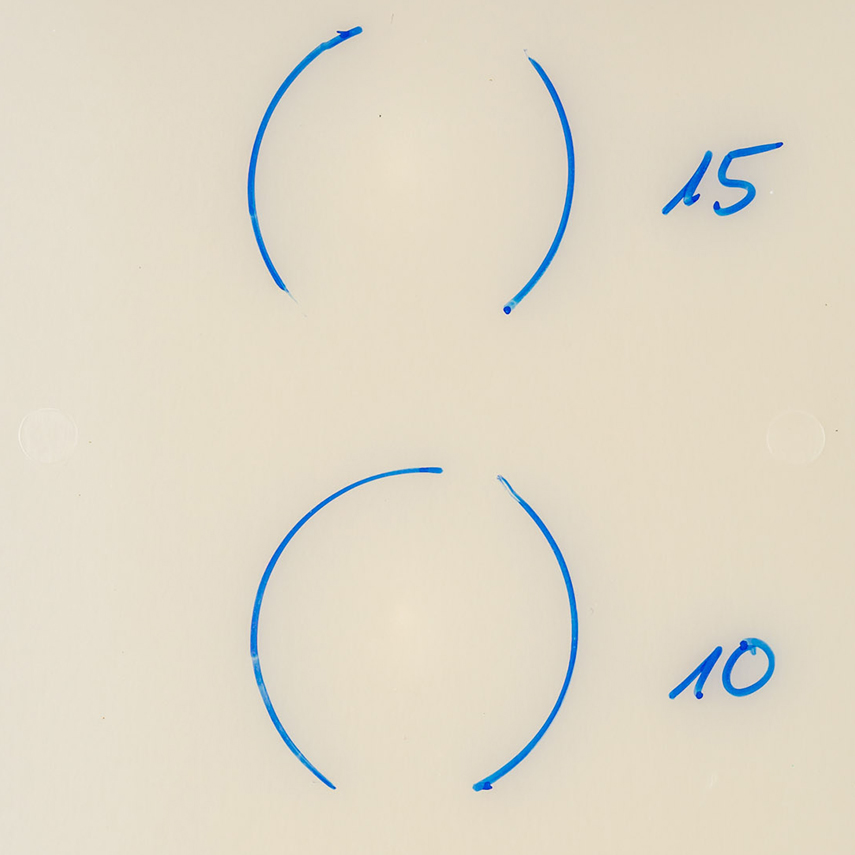

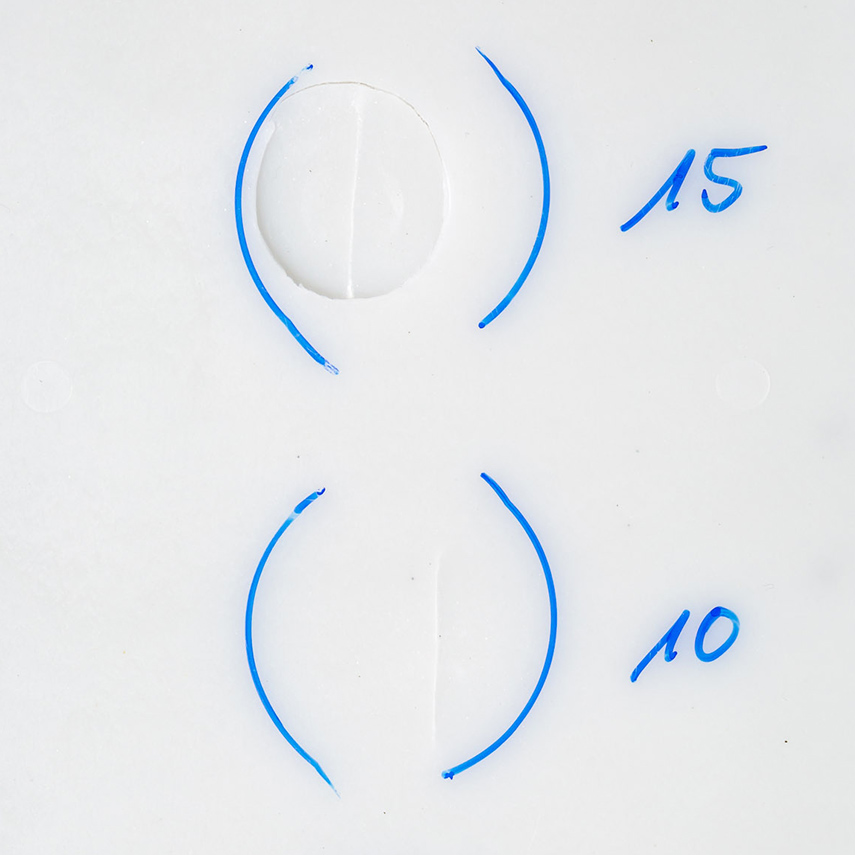

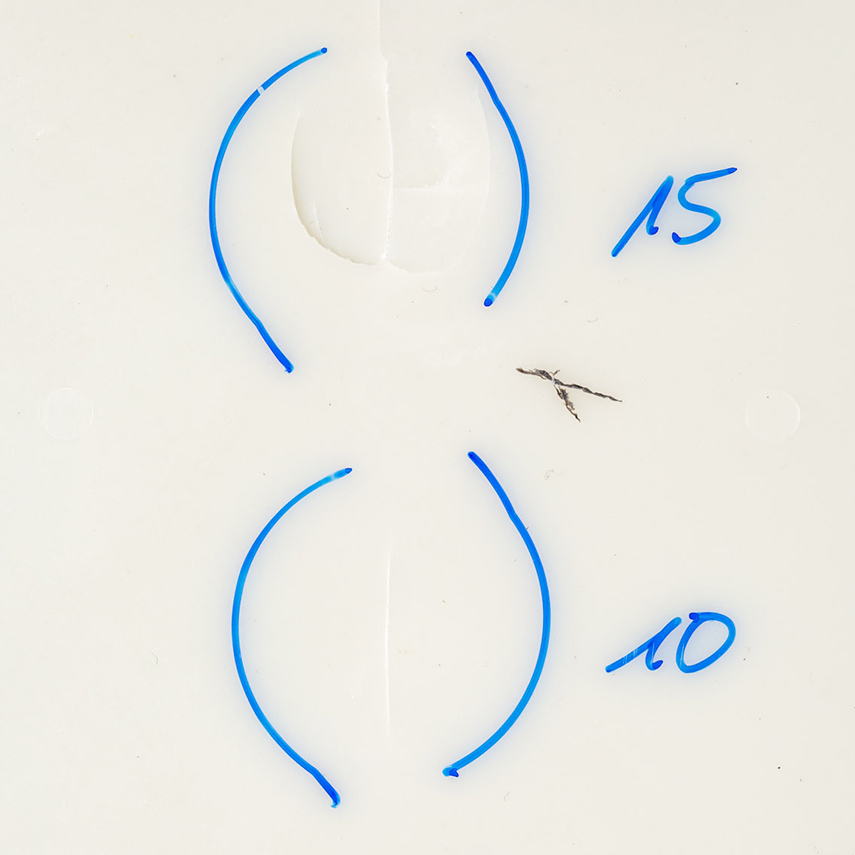

Test Result 2:

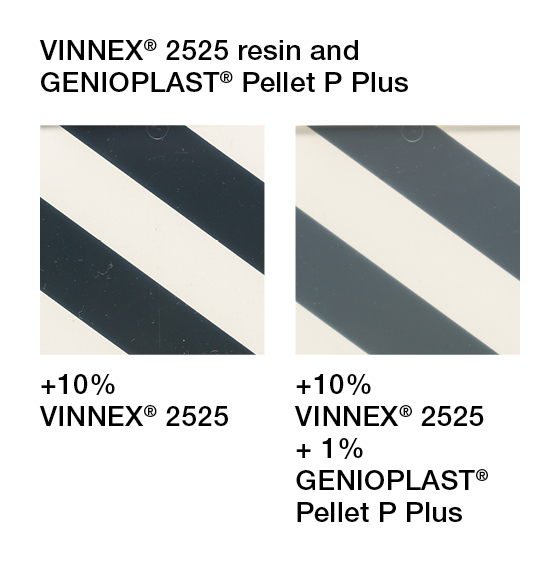

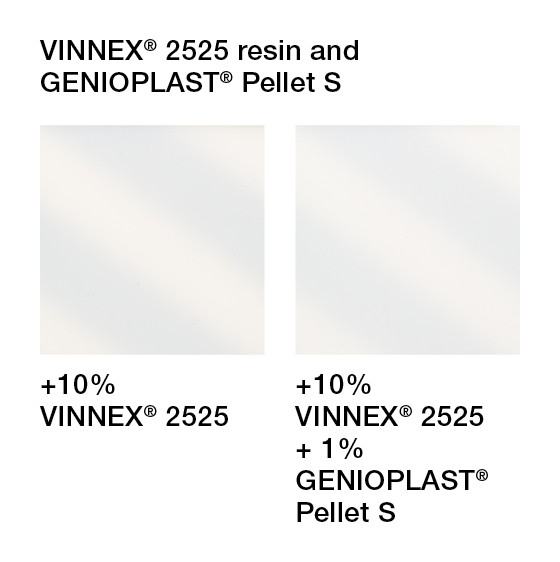

Transparent Through and Through

Biodegradable plastics must compete with many conventional plastics, and a particularly important property for food packaging is transparency. VINNEX® poly(vinyl acetate) resins and GENIOPLAST® Pellets are performance additives that can help packaging and films retain the desired degree of transparency. At the same time, they also noticeably improve the mechanical properties of the materials.

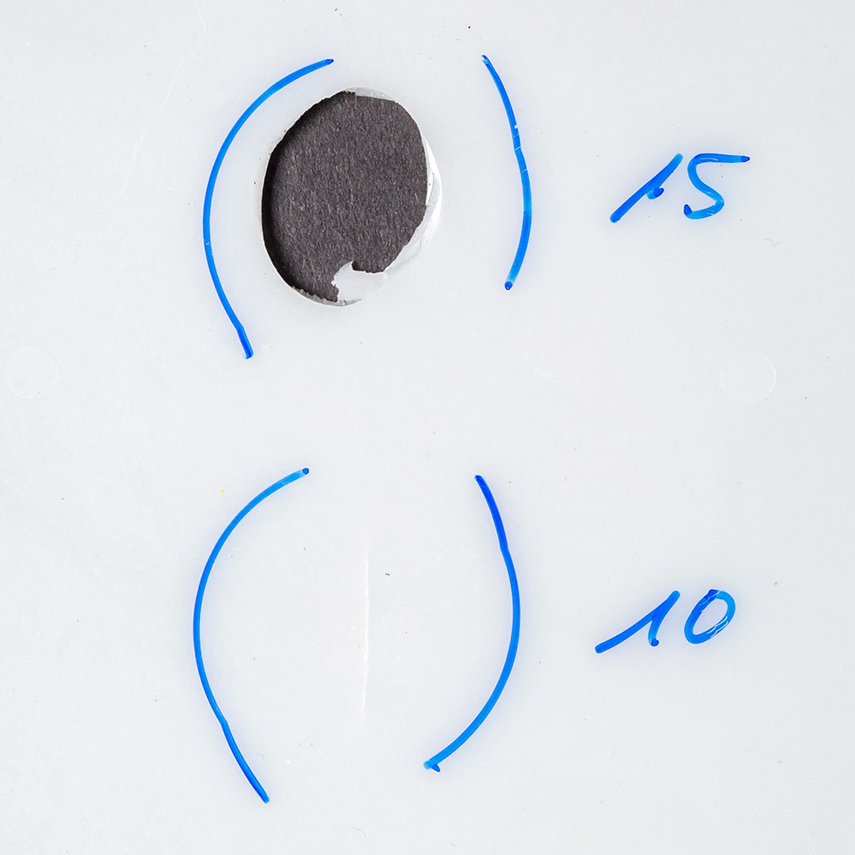

Transparency:

PLA IngeoTM Biopolymer 4043 (unfilled) with 15% CaCO3, filled

For these tests, we worked with a standard dosage of 10 to 15% VINNEX® and 1% GENIOPLAST® Pellets. As the photos show, this blend had no negative impact on the transparency of filled and unfilled bioplastics.

Material A: PLA IngeoTM Biopolymer 4043 D, unfilled

Material B: BioPBSTM FZ91PM, filled

Test Result 3:

Resistant to Scratches

Combining VINNEX® and GENIOPLAST® additives greatly increases resistance to scratching and abrasion in bioplastics, thereby reducing the risk of damage during shipping or storage.

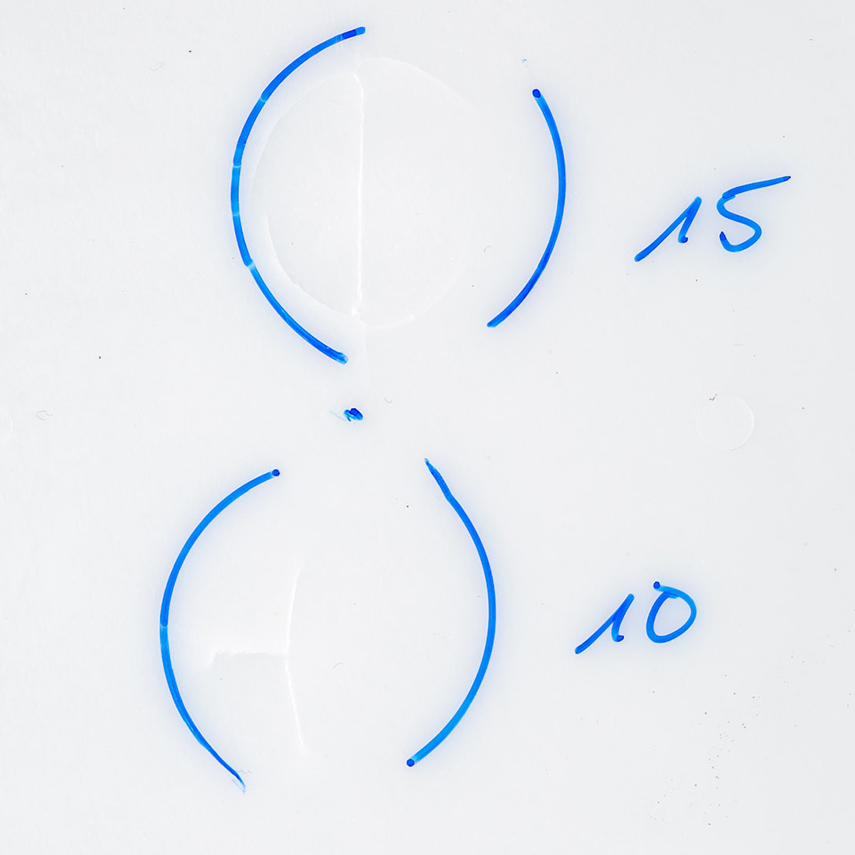

Scratch resistance:

PLA IngeoTM Biopolymer 4043 (unfilled) and BioPBSTM FZ91PM +15% CaCo3 (filled)

When VINNEX® is incorporated at a concentration of 15%, a 2% addition of GENIOPLAST® is enough to make thermoplastics significantly less susceptible to scratching. Scratch depth is many times less than that of biopolymers modified purely with VINNEX® (see middle and final bars).

PLA IngeoTM 4043 D, unfilled

BioPBSTM FZ91PM +15% CaCo3, filled

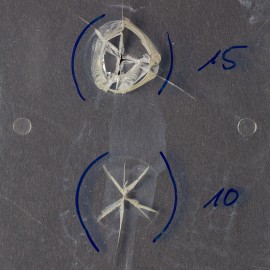

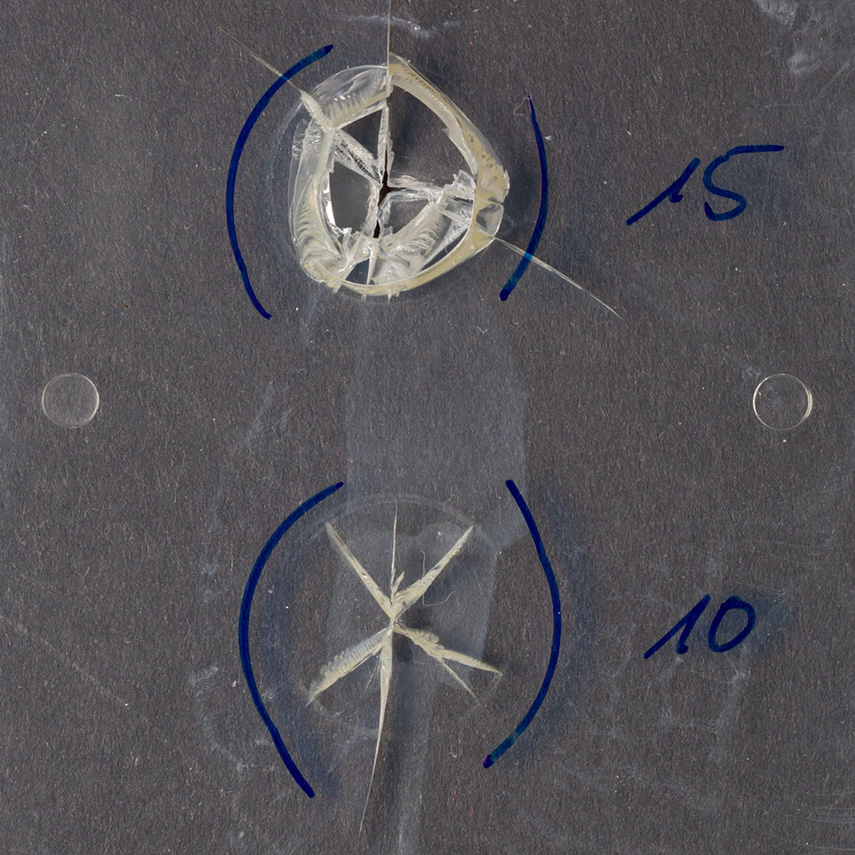

Test Result 4:

Impact Resistance

Surface stability of biopolymers can be significantly improved through the use of VINNEX® and GENIOPLAST®. Their effects on impact strength are particularly beneficial, as they allow the material to do a better job of absorbing the energy from shocks and impacts.

Impact strength:

PLA IngeoTM Biopolymer 4043 (unfilled) and BioPBSTM FZ91PM +15% CaCO3 (filled)

In combination with silicone-based GENIOPLAST®, VINNEX® significantly increases impact strength of thermoplastic biopolymers. When VINNEX® is incorporated at a concentration of 10 to 15%, a 1% dosage of GENIOPLAST® Pellets is enough to produce significant effects.

Material A: PLA IngeoTM Biopolymer 4043 D, unfilled

Material B: BioPBSTM FZ91PM, filled

What Property Set Do You Need?

We would be happy to test more combinations of bioplastics for you and determine the property set that’s right for you. Simply contact our technical services.

Contact