- Home

- Products & Services

- Applications

- Renewable Energies

- Solar Energy

Solar Energy

As a leading manufacturer of polysilicon and a pioneer in silicones, WACKER has been an important partner of the solar industry since its beginning. Today the company offers the solar industry a portfolio of future-proof products along the entire solar value chain.

Manufacture of Solar Cells

WACKER is a world market leader in polysilicon, with production sites in Burghausen, Nünchritz and Charleston and an annual production capacity of up to 80,000 metric tons. WACKER has a long history of producing polysilicon, ensuring high and consistent quality.

- Outstanding purity (no other material in the world is produced on an industrial scale with this level of purity)

- Certified according to ISO 9001, ISO 14001, OHRIS and OHSAS

- Complete spectrum of polysilicon products

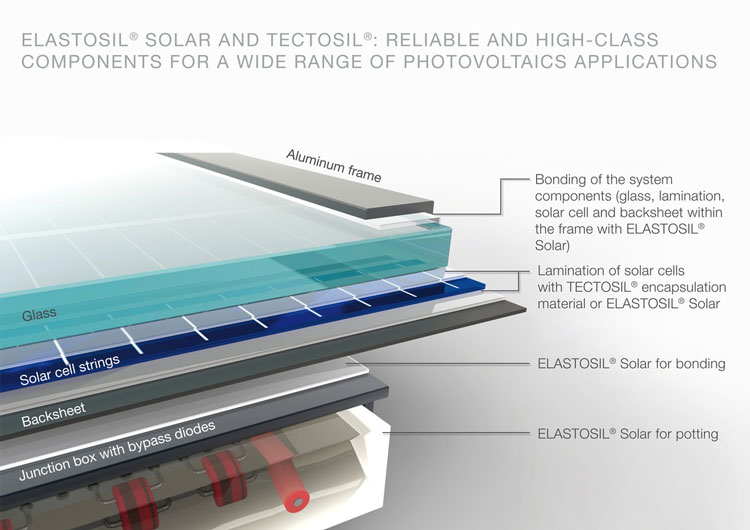

Bonding of Photovoltaic Components

ELASTOSIL® solar silicone rubber grades are optimal for bonding solar-cell laminates into an aluminum frame. They also perform outstandingly in applications in which components such as connection boxes need to be fixed to a backing.

Reliable and high-class components for a wide range of photovoltaic applications

Benefits:

- Adhesion to typical substrates (glass, aluminum, Tedlar®, EVA, etc.)

- Neutral crosslinking

- Long-term resistance to weathering and UV

- Easy processing

Encapsulation of Solar Cells

ELASTOSIL® Solar comprises low-viscosity, fast-curing silicone rubber grades that are ideal for encapsulating flexible and rigid solar modules.

Benefits:

- Adhesion to typical substrates

- Very high transparency

- Rapid curing

- Long-term resistance to weathering and UV radiation

- No yellowing

Connector Encapsulation

In the ELASTOSIL® Solar range, specific materials are especially designed for the potting of junction boxes. The two-part grades are low viscous, pourable, and ready to use.

Benefits:

- Low viscosity and rapid curing

- Low modulus for reducing thermomechanical stress

- Protection of bypass diodes against moisture penetration

- Improved heat dissipation

Production of CPV Modules

ELASTOSIL® Solar silicone elastomers make CPV module production efficient and reliable and are used in various ways of applications.

Applications:

- Molding of SOG (silicone on glass) Fresnel lenses panels (primary optics)

- Bonding of the secondary optical element to the solar cell

- Effective heat management by bonding the solar chip to the heat sink unit

- Glueing the primary optics and the back panel with the frame

Benefits:

- Excellent adhesion to typical substrates (glass, aluminum, multiple junction cells, etc.)

- Neutral crosslinking

- Long-term resistance to weathering and UV

- No yellowing

- Easy processing and rapid curing

- Outstanding heat resistance

Solar Thermal Energy

Self-adhesive ELASTOSIL® Solar silicones ensure permanent bonding between the glass cover and the collector housing.

Benefits:

- Outstanding heat and weathering resistance

- Long-term stability to UV radiation

- Particularly suitable for applications involving harsh conditions

Concentrated Solar Thermal Energy

HELISOL® silicone fluid is the key heat transfer medium in concentrated solar power (CSP) plants. It features a very high heat resistance and durability and enables efficiency levels in solar thermal power plants that can’t be achieved with conventional heat-transfer media.

Schematic draw of a parabolic trough plant.

HELISOL® heat transfer fluids allow for a significant power block efficiency increase in large-scale applications and raise the temperature limit up to 425 °C. Moreover, HELISOL® heat transfer fluids have a significantly reduced hydrogen formation during operation compared to organic thermal oils.

Benefits of HELISOL® heat transfer fluids

- Exceptional thermal stability

- Highest max. working temperature: 425 °C

- Very broad temperature range: -40 to 425 °C

- Low pour point: < -40 °C

- Lower hydrogen formation

- Low fouling potential