A Molecule Makes History

Inventions in chemistry are rarely based on a raw material alone. They usually require a mixture of chance, curiosity, persistence and boldness. Vinyl acetate is a perfect example of this. 100 years ago, it was initially admired as a “test-tube curiosity.” Today, VAM is an important building block for success for WACKER and numerous industries that use vinyl acetate copolymers and terpolymers.

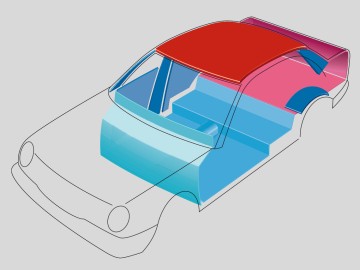

Application Range of Polymer Binders

WACKER POLYMERS is the Group’s second largest business division. It is the market leader in dispersible polymer powders and a leader in vinyl acetate-ethylene dispersions (the chart shows approximate percentages for 2020).

Vinyl Acetate – a Raw Material for Many Industries

Whether in construction materials, paints, nonwovens, carpets, packaging, composites, plastics or road surfaces – polymer binders and additives from WACKER find use in the most diverse of industries. Production requires only two starting materials: acetic acid and ethylene. These can react to form vinyl acetate monomer (VAM) – one of the key raw materials for almost all of the products sold by WACKER POLYMERS.

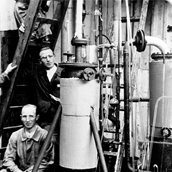

1921: an Interesting Discovery

This success story began in 1921 at the “Consortium für elektrochemische Industrie,” WACKER’s R&D facility founded in 1903. There, while working on experiments on the thermal synthesis of diacetate, Dr. W. Haehnel discovered how vinyl acetate can be manufactured in an economically feasible manner. An interesting discovery – but how to make use of it? With the exception of Bakelite, synthetic polymers were virtually unknown back then. Hence, the discovery was not considered to be economically promising at that time.

1921 forecast:

Industrial manufacture of vinyl acetate will never exceed 1.5 metric tons per month.

2021 fact:

WACKER now produces well over 150,000 metric tons per year at its Burghausen site.

1924: the First Polyvinyl Acetates

Surprisingly, this research persisted at the Consortium. Fritz Klatte at Griesheim-Elektron had already discovered that vinyl acetate is “easy” to polymerize in 1912. However, the process was so uncontrolled and "explosive" that the experiments and any associated patents, also for PVC, were abandoned. In 1924, Dr. W.O. Hermann succeeded in making polymerization safe enough for a full-scale plant by separating the reaction phases. Constructed in Burghausen in 1928, this plant produced the first polyvinyl acetates in 1930: VINNAPAS® solid resins.

Go to productsIndispensable to This Day: VINNAPAS® Solid Resins

VINNAPAS® solid resins are still indispensable in many applications and industries. Polyvinyl acetates are thermoplastic, homogeneous, colorless, tasteless and odorless, and pose no known physiological risks.

1935: Manufacture of Polyvinyl Chloride (PVC)

Over the following years, Dr. H. Berg developed the suspension polymerization process for polyvinyl chloride, for which WACKER submitted a patent application in 1935. VINNOL® vinyl chloride copolymers and terpolymers are still classics in WACKER’s product range today.

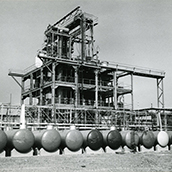

More about VINNOL® resins1957: a New Method

The big breakthrough for VINNAPAS® copolymers began after the Second World War. The construction industry, in particular, discovered the benefits of polymer dispersions in mortars, plasters and paints. However, manufacturing based on calcium carbide was rather expensive. In 1957, chemists at the Consortium succeeded in producing acetaldehyde from ethylene – which was much cheaper – for the first time. This so-called 2nd WACKER Process remains a milestone to this day and features in all organic chemistry textbooks. At WACKER, it laid the foundation for our present-day integrated ethylene production system. In 1960, the world’s first full-scale production plant went on-stream at WACKER’s Cologne site. The plant in Burghausen followed in 1978. As of 2020, 5 million metric tons of vinyl acetate monomer have been produced here.

Leaders in Many Industries: VINNAPAS® Dispersions and Dispersible Polymer Powders

WACKER’s portfolio contains many polymer dispersions, including PVAc homopolymers and vinyl acetate-ethylene (VAE) copolymers and terpolymers. Dispersible polymer powders are produced by spray drying, which was first developed at WACKER by Dr. M. Ivanovits in 1953. These powders have played a key role in the success of the dry-mix mortar industry.

More about VINNAPAS® dispersions More about VINNAPAS® dispersible polymer powders2022: VINNAPAS® eco Based on Acetic Acid Sourced from Renewable Resources

After 100 years, a new age is dawning for vinyl acetate (VAM) production. Consistent with the sustainable development goals of the Paris Agreement, WACKER has set itself the goal of achieving carbon neutrality by 2050. To this end, it needs a new raw-materials base for production.

A first step has already been taken in this direction: since 2018, WACKER has already been able to supply various polymers produced using the biomass balance method – up to 100% of the required fossil raw materials are replaced by renewable resources in the supply chain.

Go to productsMilestones of Vinyl Acetate Chemistry

1921:

Dr. W. Haehnel discovers a method of economically producing vinyl acetate for the first time

1924:

The first VAM pilot plant starts operation at the Consortium

1928:

The first large production plant for VAM is completed in Burghausen

1930:

Start of polyvinyl acetate production

1953:

Dr. M. Ivanovits begins developing dispersible polymer powders based on polyvinyl acetate dispersions

1957:

The 2nd WACKER Process enables the manufacture of acetaldehyde from petrochemical-based ethylene

1960:

At the new WACKER site in Cologne, acetaldehyde is produced from ethylene on an industrial scale for the first time worldwide

2018:

With VINNAPAS® eco (formerly VINNECO®), WACKER offers polymer binders produced with bio-based acetic acid